Production method of 360-degree spiral stair with cambered box beams

A technology of spiral staircases and manufacturing methods, applied in the direction of stairs, etc., can solve the problems of wasting tire frame materials, difficulty in web plate assembly, and difficult correction, and achieve the effects of reducing energy, reducing production cycle and construction difficulty, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

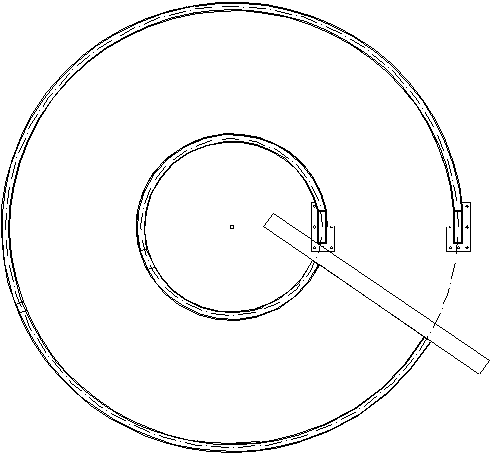

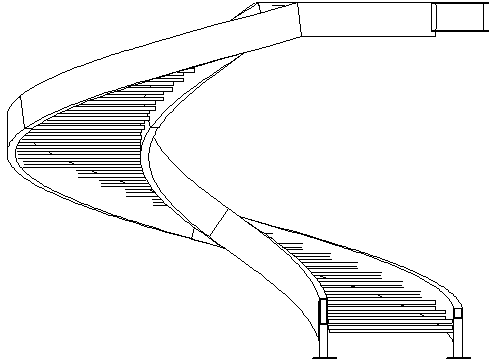

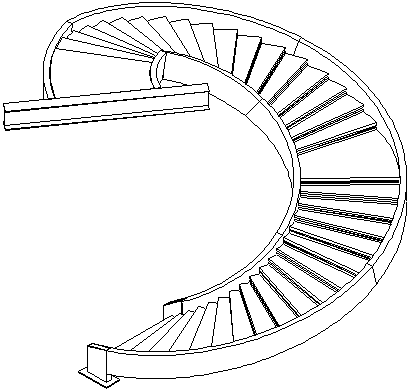

[0038] see figure 1 — image 3 , the present invention relates to a 360° revolving staircase with twisted box beam. The height of the staircase is about 6110mm, the maximum outer diameter is 8m, and the total weight is about 9 tons. 600×150×16×16, the material is Q345B. In addition, it also includes steps (patterned steel plate t=4.5) and 2 square columns. The staircase is welded by box-shaped ladder beams on both sides, steps, and bottom columns (the H-shaped steel at the top of the staircase does not belong to the staircase components). The specific steps of the manufacturing method are as follows:

[0039] (1) Stakeout material

[0040] Stake out the parts of the spiral staircase through the lofting software, and import the coordinates of each point in the three-dimensional space of the flange plate and the web of the twisted box beam in the actual design detail drawing and the XY coordinates of the two-dimensional plane expansion into the CNC cutting machine. material....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com