Production method of continuous casting tundish combined turbulence controller

A technology of turbulent flow controller and continuous casting tundish, which is applied in the field of continuous casting refractory production technology, which can solve the problems of complex preparation process, poor overall assembly quality, and complex tire mold design, so as to reduce the cost per ton of steel and improve assembly quality , The effect of simplifying the tire mold design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

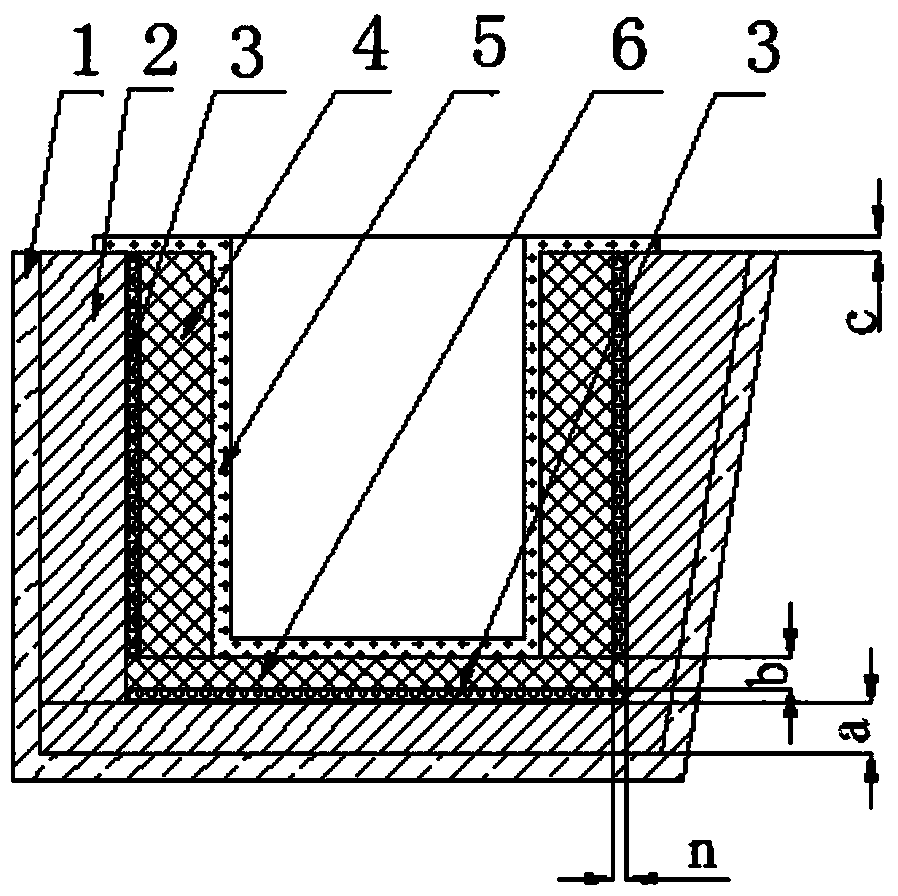

[0038] A compound turbulence controller for continuous casting tundish, the structure is as follows figure 1 , including a shell 2, a bottom plate 6, a sleeve core 4, an expansion joint 3, and an anti-oxidation coating 5. The bottom plate 6 is positioned on the bottom of the inner cavity of the shell 2, the bottom of the sleeve core 4 is positioned on the bottom plate 6, and the sleeve core 4 The longitudinal centerline coincides with the longitudinal centerline of the inner cavity of the casing 1, and an expansion joint 3 is provided between the casing 2 and the bottom plate 6, and between the casing 2 and the sleeve core 4, and an anti-oxidation coating 5 is applied on the outer surface of the sleeve core 4.

[0039] The casing 2 of the composite turbulence controller is cast and molded with magnesium castables. The bottom plate 6 of the composite turbulence controller is built with machine-pressed MT-14 magnesia-carbon bricks, and its length, width, and height are 300mm, 15...

Embodiment 2

[0053] Embodiment 2, as described in Embodiment 1, the difference is:

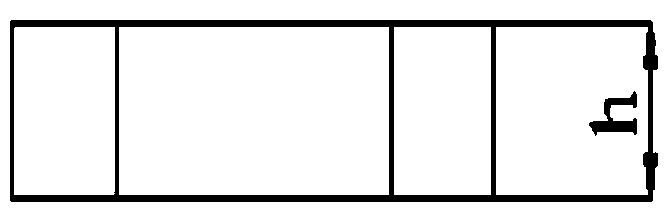

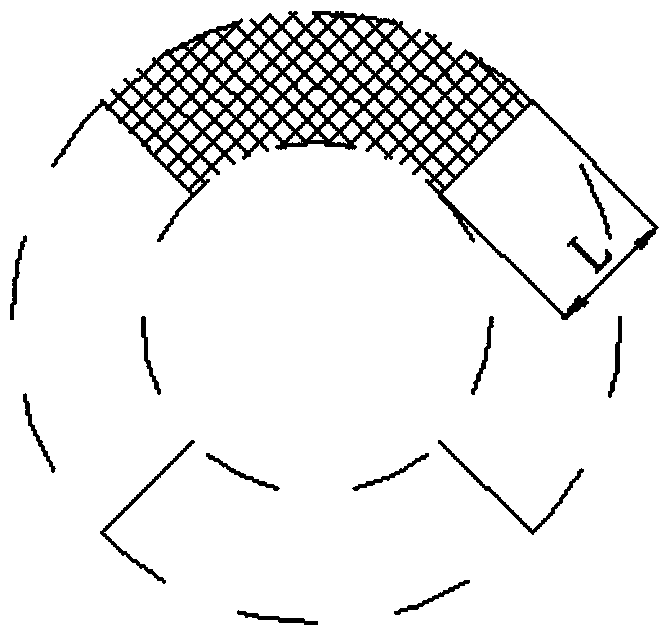

[0054] The thickness b of the bottom of the composite turbulence controller is 65 mm; the sleeve core 4 of the composite turbulence controller adopts machine-pressed "fan-shaped" magnesia-carbon bricks to build the side wall of the sleeve core 4, which is divided into upper and lower parts. Ring magnesia-carbon brick masonry, the height h of the "fan-shaped" magnesia-carbon brick is 100mm, and the thickness L of the "fan-shaped" magnesia-carbon brick is 100mm; the material used as the expansion joint is refractory asbestos cloth, and the thickness n is 2.0mm; The anti-oxidation coating is made of an anti-oxidation magnesia-chromium carbonaceous smear material, and the thickness c is 15mm.

[0055] The preparation method of the compound turbulence controller of the continuous casting tundish comprises the following steps:

[0056] (1) The tire mold 1 of the composite turbulence controller shell 2 is prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com