Dual-mode drawing die structure

A mold and water tank drawing technology, applied in the direction of metal drawing forming tools, wire drawing dies, metal wire drawing, etc., can solve the problems of shrinking, broken wire, uneven deformation of drawing steel wire, etc., to achieve convenient circle diameter, reduce The effect of precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

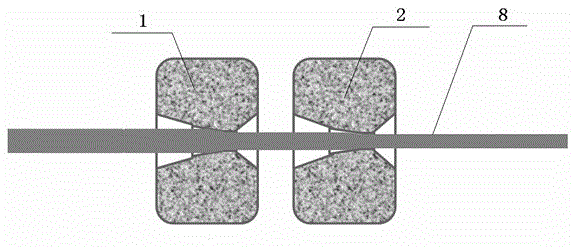

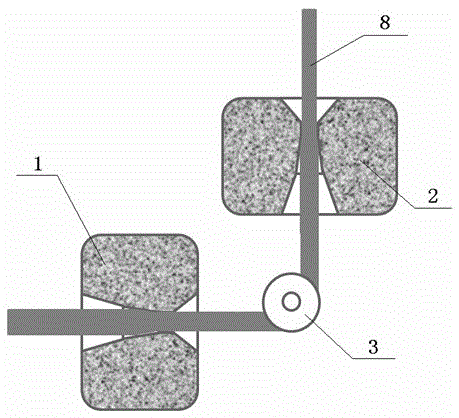

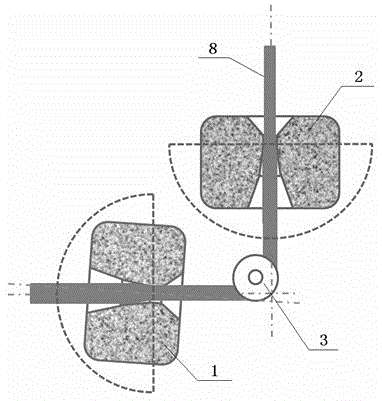

[0030] Embodiment one: see figure 2 , image 3 , Figure 4 with Image 6 Shown, a kind of double mold drawing die structure comprises front mold 1 and back mold 2, and a guide wheel 3 is arranged between front mold 1 and back mold 2; Described front mold 1 and back mold 2 all can be in Rotate at an angle of 0 to 10° in the spherical arc surface centered on the respective sizing belts; the front mold 1 and the rear mold 2 are respectively fixed in the grooves of the mold frame 4 through the mold mouth 6, and the outer mold mouth 6 The thread cooperates with the internal thread of the groove of the mold base 4 to fix the front mold 1 or the rear mold 2 arranged in the groove of the mold base 4; the mold base 4 is arranged on the support 5, the bottom of the mold base 4 is a spherical arc surface, The adjusting screw 7 is fixed to the support 5 , and the support 5 is provided with a mating surface that matches the spherical arc surface at the bottom of the formwork 4 to make ...

Embodiment 2

[0031] Embodiment two: see Figure 5 with Image 6 As shown, it is the same as the first embodiment, the only difference is that three guide wheels 3 are arranged between the front mold 1 and the rear mold 2 . This structure can be kept before and after double-mode drawing, and the steel wire 8 is still on the same straight line, that is, with figure 1 The wire routing of the conventional dual-mode is consistent, which is convenient for the winding and routing of the front and rear reels (or tower pulleys) of the dual-mode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com