Nozzle Cleaning Fixture

A technology for cleaning jigs and jigs, applied in cleaning methods and utensils, cleaning methods using gas flow, chemical instruments and methods, etc. Good maintenance, avoid personnel waste and excessive time investment, optimize the effect of maintenance process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described with reference to the accompanying drawings. In the drawings of the specification, elements having similar structures or functions will be denoted by the same element symbols. The drawings are only for the convenience of illustrating various embodiments of the present invention, and are not intended to describe the present invention exhaustively, nor limit the scope of the present invention.

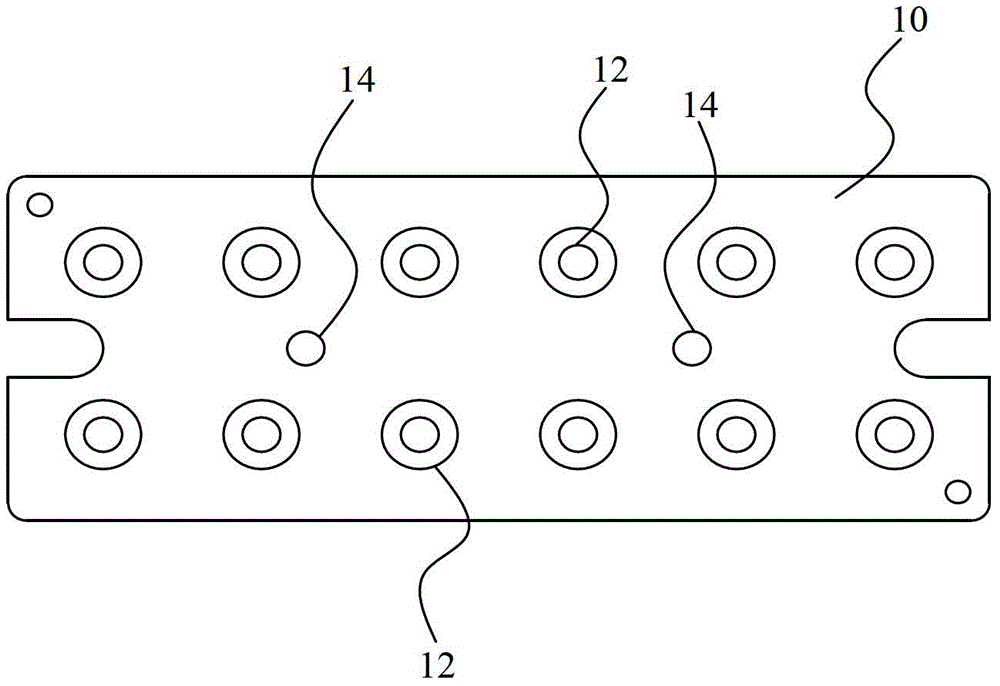

[0028] figure 1 The schematic structure of the base of the nozzle cleaning jig under a specific embodiment of the present invention is shown. In this embodiment, the nozzle cleaning jig includes a base 10 and a cover plate 20 (see figure 2 ), the base 10 is provided with a plurality of nozzle cleaners. The nozzle cleaner includes a cylindrical nozzle hole 12 for inserting the nozzle and cleaning it. Those skilled in the art can understand that the form of the nozzle cleaner is not limited, and can also be other structures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com