Preparation method of tiny hole type multihole clay heterogeneous material

A clay and heterogeneous technology, which is applied in the field of preparation of microporous porous clay heterogeneous materials, can solve the problems that the adsorption effect is difficult to meet the practical requirements, and achieve the effects of reducing indoor health risks, enhancing adsorption capacity, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Mix 180g ethyl orthosilicate and 60g diphenyldiethoxysilane evenly to form 240g mixed liquid, mix 2g organic bentonite and 40g dodecylamine, stir at 50°C for 30min, then add 240g mixed liquid, stir at 35°C for 12h ; The solid obtained after suction filtration was air-dried naturally; the muffle furnace was programmed to heat up to 600°C at 2°C / min, and kept for 4 hours to obtain a microporous PCH material, which was designated as PCH25.

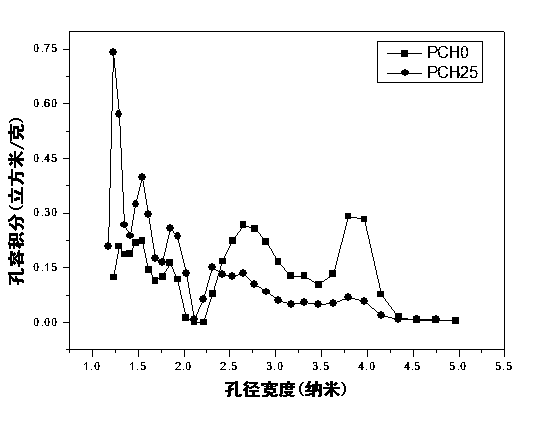

[0019] as table 1, figure 1 As shown, the specific surface area and micropore specific surface area of PCH25 are larger than that of PCH0; compared with PCH0, the micropore content of PCH25 is significantly increased, and the mesopore content is significantly reduced, indicating that the adsorption potential of PCH25 is significantly stronger than that of PCH0.

[0020] Table 1 Specific surface area and micropore specific surface area of different PCH adsorption materials

[0021] Adsorbent material Specific surface are...

Embodiment 2

[0023] Mix 120g ethyl orthosilicate and 120g diphenyldiethoxysilane evenly to form 240g mixed solution, mix 2g organic bentonite and 40g dodecylamine, stir at 50°C for 30min, then add 240g mixed solution, stir at 35°C for 12h , to obtain the precursor solution; the solid obtained after suction filtration of the precursor solution was naturally air-dried; the muffle furnace was programmed to heat up to 600°C at 2°C / min, and kept at 600°C for 4 hours to obtain the microporous PCH material.

Embodiment 3

[0025] Mix 60g ethyl orthosilicate and 180g diphenyldiethoxysilane evenly to form 240g mixed solution, mix 2g organic bentonite and 40g dodecylamine, stir at 70°C for 30min, then add 240g mixed solution, stir at 35°C for 12h , to obtain a precursor solution; the solid obtained after suction filtration of the precursor solution was dried at 70°C; the muffle furnace was programmed to heat up to 600°C at 2°C / min, and kept at 600°C for 4 hours to obtain a microporous PCH material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com