Apparatus and method for preparing liquid droplets present in the gas phase

A droplet and gas phase technology, applied in the field of manufacturing equipment for droplets and liquid marbles in the gas phase, can solve the problems of liquid marbles failing to achieve large-scale industrial applications, achieve high output and reduce usage , good wrapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

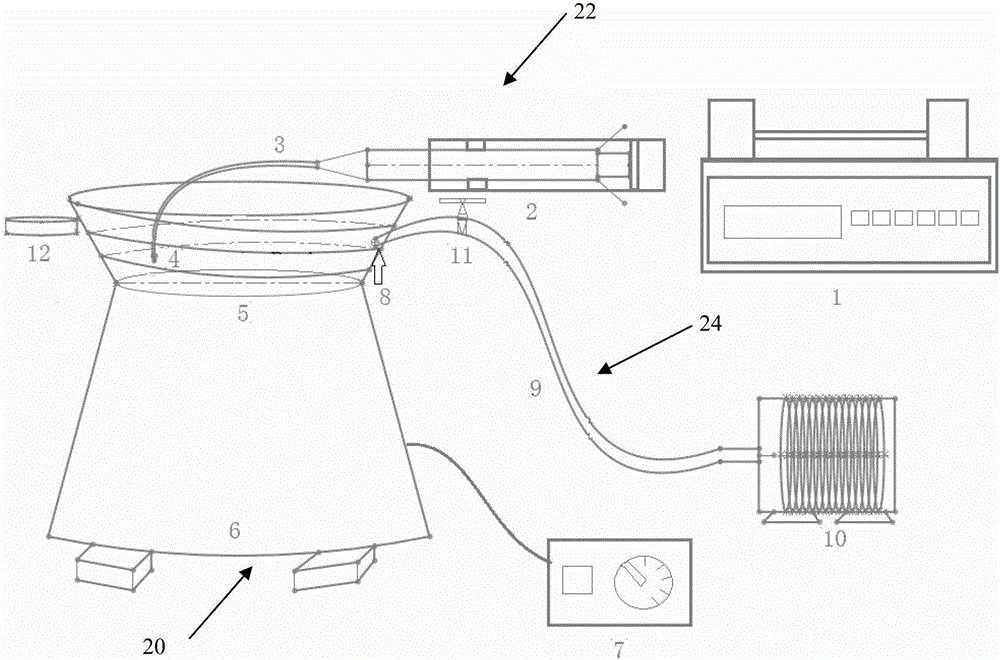

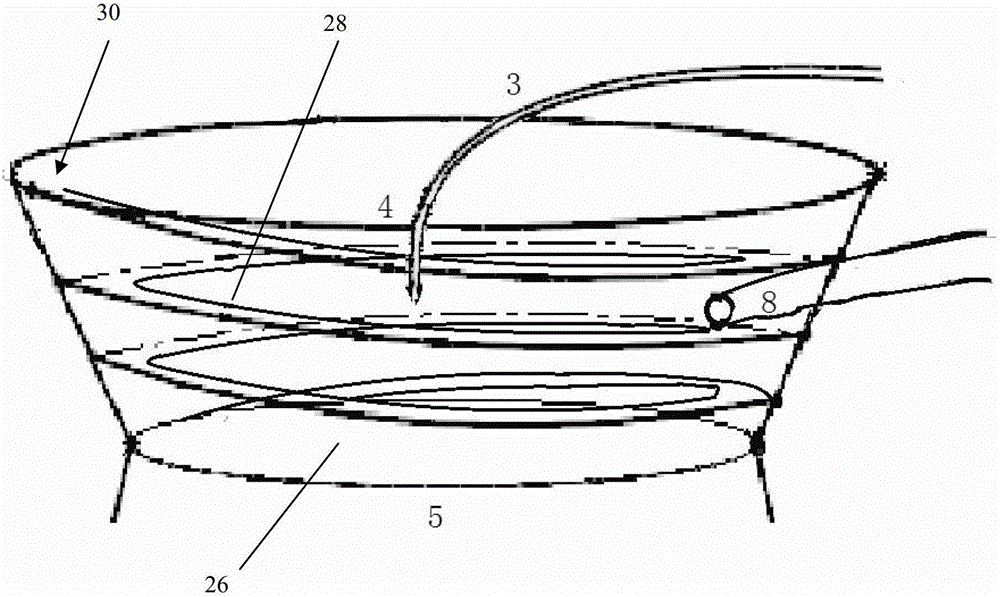

[0038] The method for preparing liquid marbles (or other macroscopic liquid droplets existing in the gas phase) of the present invention will be described below with reference to the accompanying drawings. First, optionally, waxing or other hydrophobic treatment can be performed on the inner surface of the top plate 5 of the vibrating plate feeding device 20; the highly hydrophobic solid particles (powder) 13 are laid on the bottom, and the surface is covered at a certain height with a covering device. These solid particles (powder) cover up.

[0039] Next, the capillary glass tube 4 of the droplet generating device is inserted into the first opening of the covering device, preferably the end of the capillary glass tube 4 is no more than about 3 inches from the bottom of the vibrating plate top plate 5 (or the solid particles (powder) are laid on it). cm. Prior to this, the steps of preparing the droplet generating device 22 can also be carried out, such as injecting the liqu...

example 1

[0044] Combine below Figure 4 -5 describes an example of manufacturing the liquid marble of the present invention.

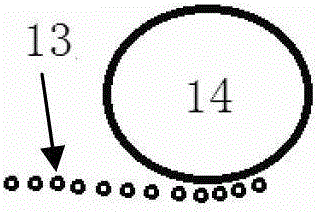

[0045] In this example, the liquid marble 15 is basically produced by the method described above. Wherein, the surface of the top plate is coated with wax so as to have certain hydrophobicity. And the above-mentioned highly hydrophobic solid particles (powder) are hydrophobic smoky silica gel powder, and the liquid solution is roughly a sodium alginate solution with a concentration of 4% (weight), and these sodium alginate solutions preferably have blue methylene blue . And the liquid droplets are produced by the liquid generating means to be less than or equal to about 2.5mm, and in this example the droplets are also substantially larger than about 2mm. In addition, in this example, the top plate of the vibrating plate feeding device can make the hydrophobic aerosol silica gel can have a peak vibration rate of at least about 300 mm / s and a vibration frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com