Vacuum pulse-type gutta-percha extraction device

An extraction device and a technology of vacuum pulsation, applied in the field of vacuum pulsation type eucommia gum extraction device, can solve the problems of waste of eucommia gum resources, large mass transfer resistance, loss, etc., and achieve automatic control and drainage, realize condensation recovery, and purify exhaust gas. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

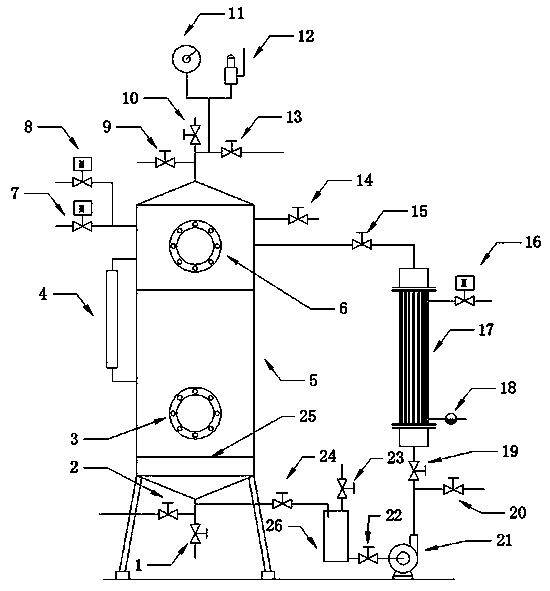

[0019] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0020] Such as figure 1 The shown vacuum pulsation type eucommia gum extraction device includes an extractor 5 and a heater 17. The extractor 5 is provided with a sieve plate 25, a discharge port 3, a feed port 6, and a solvent inlet valve 14. The sieve plate 25 is used to hold The material to be extracted; the extractor 5 is equipped with a vacuum condenser solenoid valve 7 and a vacuum breaking solenoid valve 8 to realize automatic control of vacuum connection and vacuum removal; the bottom of the extractor 5 is provided with a drain valve 1 and a steam inlet valve 2; The device 5 is also provided with a condenser valve 9, an emptying valve 10 and a compressed air valve 13; the lower end of the extractor 5 forms a loop with the upper end of the extractor 5 through a buffer tank 26, a pump 21, a heater 17; the upper end of the buffer tank 26 A decondenser valve 23 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com