Thermal radiation prevention and flame retardance knitted fabric and manufacturing method

A technology of knitted fabric and production method, which is applied in the directions of knitting, weft knitting, fabric surface trimming, etc., can solve the problems of bulky, uncomfortable, and operator injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

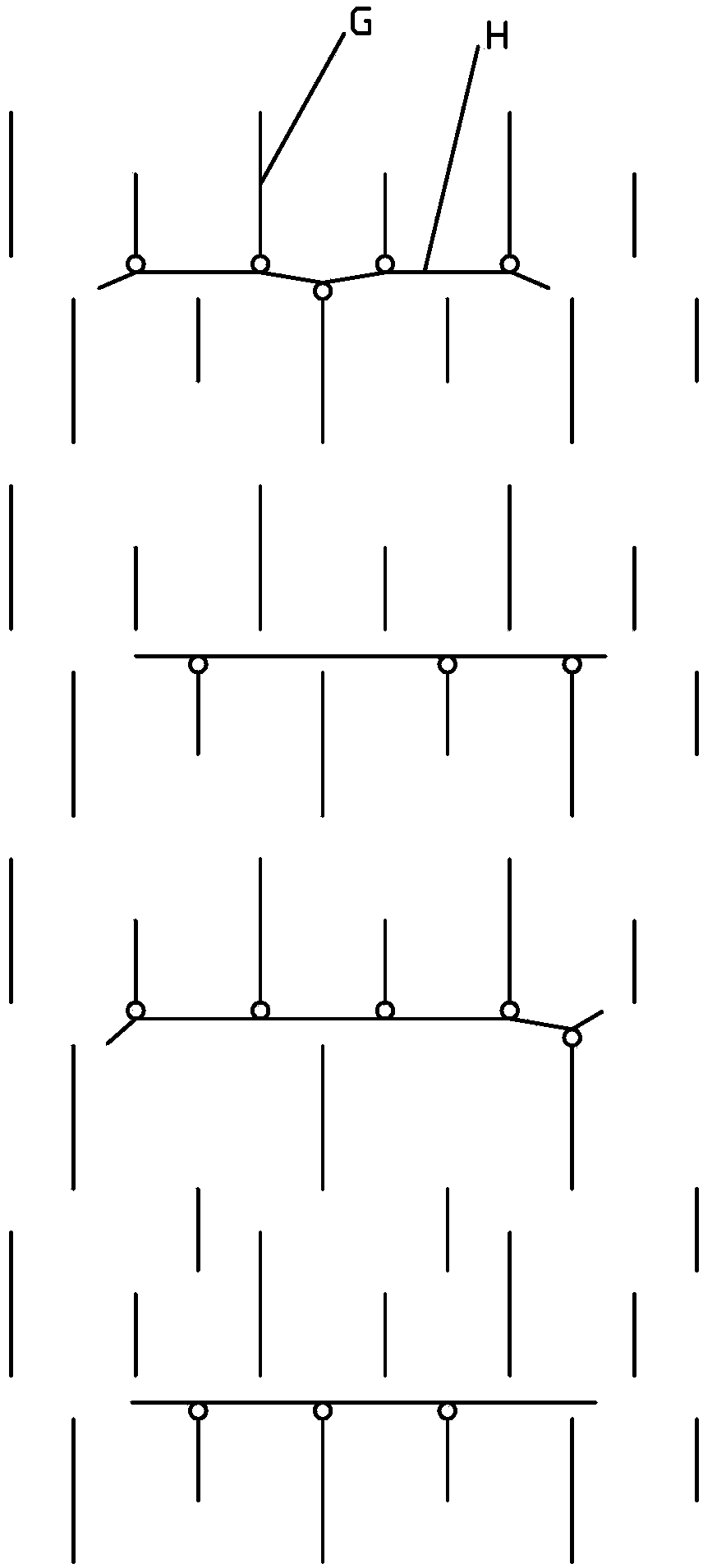

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] The embodiment of the present invention describes a heat radiation and flame-retardant knitted fabric, one side of the fabric is woven with silver-plated fiber filaments to form a silver fiber surface; wherein, the silver-plated fiber is made of nylon The filament is used as a carrier, and the silver is arranged on its surface by electrolysis or infiltration; the other side of the fabric is woven from Lenzing thermal protection fiber filaments to form a flame-retardant fiber surface, wherein the The flame retardant fiber surface is based on the Lenzing thermal protection fiber filament as the carrier, and the flame retardant medium is set on the surface by soaking. Wherein, the contents of silver-plated fiber and Lenzing thermal protection fiber in the fabric are 10%-40% and 60%-90% respectively. The Lenzing thermal protection fiber filament is 9.7tex; the silv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com