Edible film coating fresh-keeping agent and preparation method and use method of edible film coating fresh-keeping agent

A film-preserving agent and weight fraction technology, which can be used in food preservation, coating protective layer to preserve eggs, applications, etc., can solve the problems of destroying the antibacterial protection of eggshell membranes, endangering the health of eaters, and poor fresh-keeping effects. Achieve the effects of inhibiting breathing and physiological activities, prolonging shelf life, and preventing the loss of flavor substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

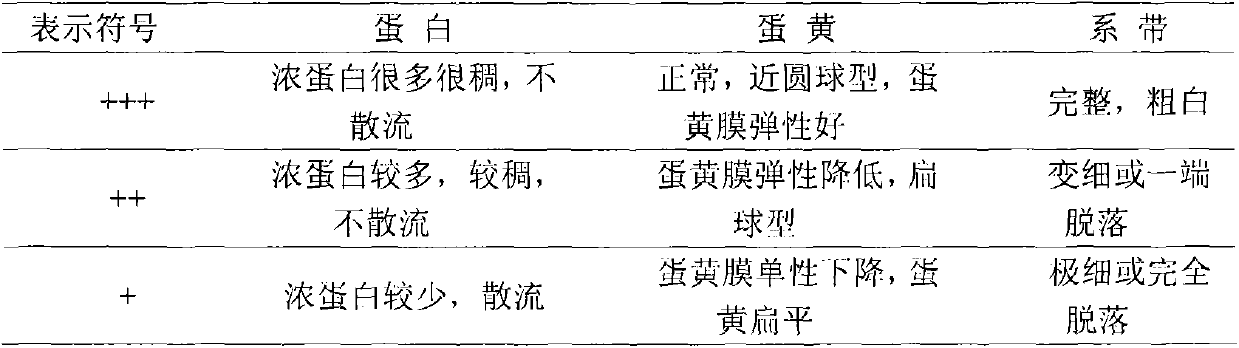

Image

Examples

Embodiment 1

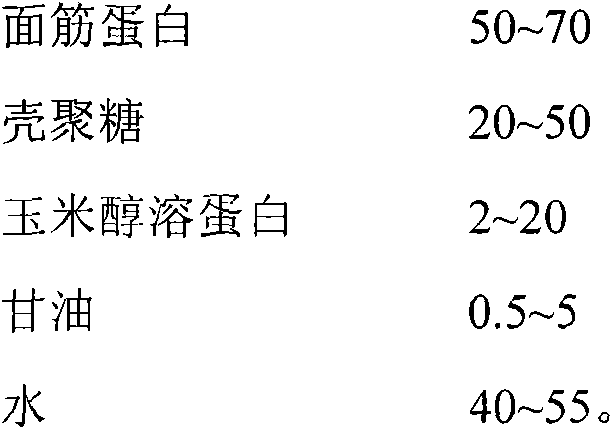

[0035] An edible film preservative, the raw material of the film preservative contains gluten, chitosan, zein and glycerin, the weight of the gluten, chitosan, zein and glycerin The score ratio is:

[0036]

[0037] Further, the raw material of the coating preservative also contains whey protein isolate and soybean protein isolate, and the weight fraction ratio of the whey protein isolate and soybean protein isolate is:

[0038] Whey protein isolate 2-5

[0039] Soy protein isolate 2-5.

[0040] Further, the raw materials of the coating preservative also contain pectin polysaccharides, and the weight fraction ratio of the pectin polysaccharides is:

[0041] Pectin polysaccharide 2-10.

[0042] Further, the molecular weight of the pectin polysaccharide is 5000-10000 Daltons.

[0043] The preparation method of described film preservative comprises the following steps:

[0044] 1) Add glycerin to water according to the above weight fraction ratio, stir at 50-60°C for 10-2...

Embodiment 2

[0056] This embodiment is a preferred solution on the basis of embodiment 1. The quality of the raw materials used is the same as that of embodiment 1, and the same part as embodiment 1 will not be repeated. Please refer to embodiment 1.

[0057] The raw material of described edible coating preservative is gluten protein, chitosan, zein and glycerin, and the weight fraction ratio of described raw material is:

[0058]

[0059] The preparation method of described film preservative comprises the following steps:

[0060] 1) Add glycerin to water according to the above weight fraction ratio, stir at 60°C for 20 minutes to fully dissolve glycerin, and then cool to room temperature;

[0061] 2) adding the gluten, chitosan, and zein into the solution obtained in step 1), and ultrasonically mixing to form a uniform mixed solution, to obtain the edible preservative for coating .

[0062] Further, the processing time of the ultrasonic mixing described in step 2) is 10 min, and the...

Embodiment 3

[0100] This embodiment is a preferred solution on the basis of embodiment 1. The quality of the raw materials used is the same as that of embodiment 1, and the same part as embodiment 1 will not be repeated. Please refer to embodiment 1.

[0101] The weight fraction ratio of the raw material gluten protein, chitosan, zein, glycerol, whey protein isolate and soybean protein isolate of the edible film preservative is:

[0102]

[0103] The edible coating film preservative can be used for the preservation of poultry eggs, and the use method comprises the following steps:

[0104] 1) Disinfection treatment: after treating the poultry eggs in water at 100° C. for 5 seconds, drain the water to obtain the poultry eggs after disinfection treatment;

[0105] 2) Preservation treatment: immerse the sterilized poultry eggs in the edible coating film preservative for 2 minutes, take them out and drain, and form a thin film on the surface of poultry eggs to obtain fresh poultry eggs;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com