Chicken essence and preparation method thereof

A chicken flavor and enzymatic hydrolysis technology, which is applied in the field of seasoning, can solve the problems of inability to satisfy chicken flavor, weak flavor of natural stewed chicken, and affecting the flavor of finished food products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

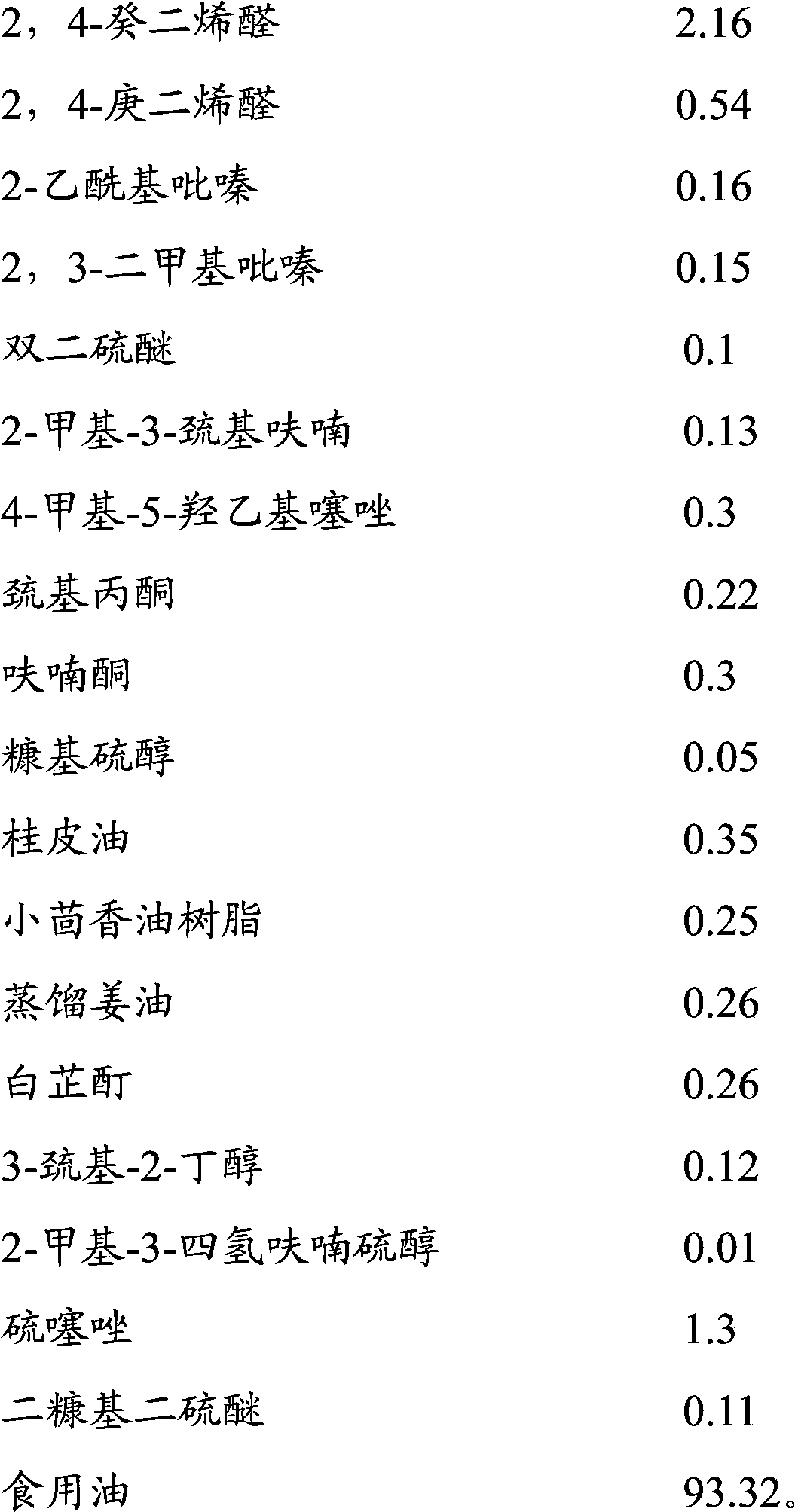

preparation Embodiment 1

[0026] S1, raw material pretreatment: take fresh chicken breast, remove tendons and fat, cut into pieces, and grind at high speed in a meat grinder to obtain minced meat;

[0027] S2, enzymatic hydrolysis: put minced meat and protease into a constant speed mixer, add deionized water, adjust the pH to 6 with 0.5mol / L sodium hydroxide solution; transfer to a constant temperature water bath at 120°C for enzymolysis reaction; , the enzyme-to-bottom ratio is 500u / g; the enzymolysis time of the enzymolysis reaction is 100min;

[0028] S3, Enzyme inactivation: Return the enzymatic hydrolysis solution of S2 to 20°C, then raise the temperature to 85°C, and keep for 15 minutes to inactivate the enzyme;

[0029] S4, Filtration: Centrifuge the solution after deactivating the enzyme in S3, wherein the centrifugation conditions for centrifugation are: centrifuge at a speed of 4500r / min for 25min, and collect the supernatant to be the hydrolyzate;

[0030] S5, drying the supernatant obtaine...

preparation Embodiment 2

[0034] S1, raw material pretreatment: take fresh chicken breast, remove tendons and fat, cut into pieces, and grind at high speed in a meat grinder to obtain minced meat;

[0035] S2, enzymatic hydrolysis: put minced meat and protease into a constant speed mixer, add deionized water, adjust the pH to 6.8 with 0.8mol / L sodium hydroxide solution; transfer to a constant temperature water bath at 100°C for enzymolysis reaction; , the enzyme-to-bottom ratio is 500u / g; the enzymolysis time of the enzymolysis reaction is 80min;

[0036] S3, Enzyme inactivation: Return the enzymatic hydrolysis solution of S2 to 20°C, then raise the temperature to 85°C, and keep for 15 minutes to inactivate the enzyme;

[0037] S4, filtration: the solution after S3 deenzyme is subjected to centrifugal treatment, wherein, the centrifugation condition of centrifugal treatment is: centrifuge centrifuges 25min with 3500r / min rotating speed, collects supernatant and is hydrolyzate;

[0038] S5, drying the ...

preparation Embodiment 3

[0042] S1, raw material pretreatment: take fresh chicken breast, remove tendons and fat, cut into pieces, and grind at high speed in a meat grinder to obtain minced meat;

[0043] S2, enzymatic hydrolysis: put minced meat and protease into a constant speed mixer, add deionized water, adjust the pH to 6.7 with 1.4mol / L hydrochloric acid solution; transfer to a constant temperature water bath at 110°C for enzymolysis reaction; The bottom ratio is 500u / g; the enzymolysis time of the enzymolysis reaction is 90min;

[0044] S3, Enzyme inactivation: Return the enzymatic hydrolysis solution of S2 to 20°C, then raise the temperature to 85°C, and keep for 15 minutes to inactivate the enzyme;

[0045] S4, Filtration: Centrifuge the solution after deactivating the enzyme in S3, wherein the centrifugation conditions for centrifugation are: centrifuge at a speed of 4000r / min for 25min, and collect the supernatant to be the hydrolyzate;

[0046] S5, drying the supernatant obtained in S4 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com