Magnetic composite microsphere loaded with precious metal quantum dots and preparation method of magnetic composite microsphere

A technology of magnetic composite microspheres and precious metals, which is applied in the preparation of microspheres, the magnetism of organic materials/organic magnetic materials, and microcapsule preparations. It can solve the problems of decreased fluorescence intensity and difficulty in controlling the amount of adsorption of quantum dots, and achieves application prospects. The effect of broad, excellent magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of magnetic polymer microspheres

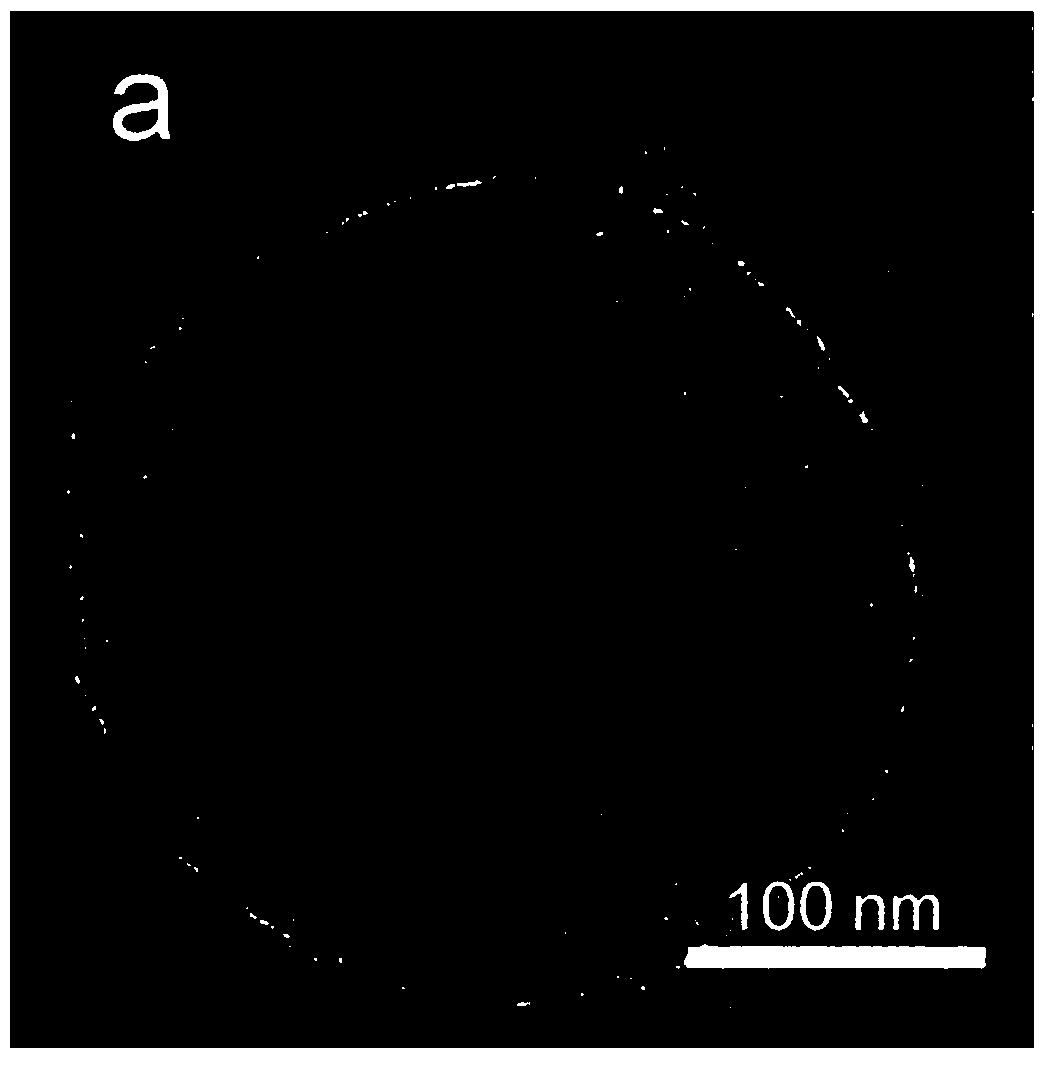

[0035] 40mg of isoalcohol diester maleate was dissolved in 40mL of deionized water, mechanically stirred for 2 hours, and 0.5g of Fe was added 3 o 4 , 3g styrene monomer, blow nitrogen, continue to stir for 12 hours, then add 30mg potassium persulfate and raise the temperature to 65°C to react for 24 hours to obtain a magnetic polymer microsphere emulsion with a core-shell structure. The structure of the obtained microspheres was characterized by transmission electron microscopy (TEM), as figure 1 , the overall size of the magnetic polymer microsphere is about 250nm, the size of the core layer is about 150nm, and the thickness of the shell layer is about 50nm; Fe 3 o 4 Contained inside the microspheres, the size is about 8nm.

[0036] (2) Loading of noble metal quantum dots

[0037] Take 1mL of the magnetic polymer microsphere emulsion in step (1) and dilute it to 10mL with deionized water; add 1mL of chloroauric a...

Embodiment 2~4

[0041] With the process of Example 1, the addition of the chloroauric acid aqueous solution in step (3) is changed to 0.5mL, 1.0mL, and 1.5mL, and the absorption wavelength of UV-vis is 530nm, 560nm, and 690nm, such as Figure 5 shown.

Embodiment 5~7

[0043] In the same process as in Example 1, the types of noble metal acid compounds in step (2) were changed to silver nitrate, chloroplatinic acid, and chloropalladium acid to obtain different types of composite microspheres. The results are shown in the following table:

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com