Cable for power transmission to aircraft and manufacturing method thereof

A cable and aircraft technology, which is applied in the field of cables for power transmission to aircraft and its manufacturing, can solve the problems affecting the localization process of airport construction and the inability to obtain technical information, etc., and achieve excellent drag resistance, good flexibility, and tensile strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings.

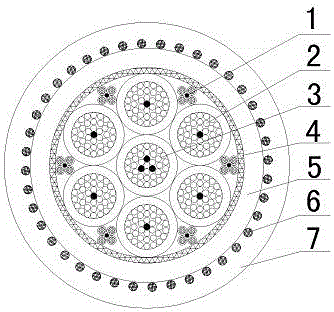

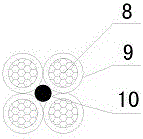

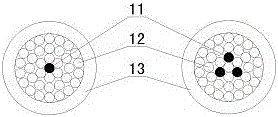

[0048] see figure 1 : This cable includes a cable core and a polyester mesh tape wrapped reinforcement layer 4, an inner sheath layer 5, an aramid wire mesh braided reinforcement layer 6, and an outer sheath layer 7 that are wrapped around the cable core from the inside to the outside in sequence; The cable core includes a three-phase power cable core and a control cable core 1, the three-phase power cable core is used to transmit three-phase 400Hz intermediate frequency power to the aircraft, and the control cable core is used to transmit control signals; the three-phase power cable core There are 7 insulated wire cores in the cable core, one of which is the neutral wire core 3, which is arranged in the center, and the remaining 6 are phase wire cores 2, which surround the periphery of the neutral wire core 3 and are evenly distributed in the circumferential direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com