Time grating linear displacement sensor

A technology of linear displacement and sensors, applied in the direction of instruments, measuring devices, electrical devices, etc., can solve the problems of high cost and achieve the effects of low cost, improved resolution and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

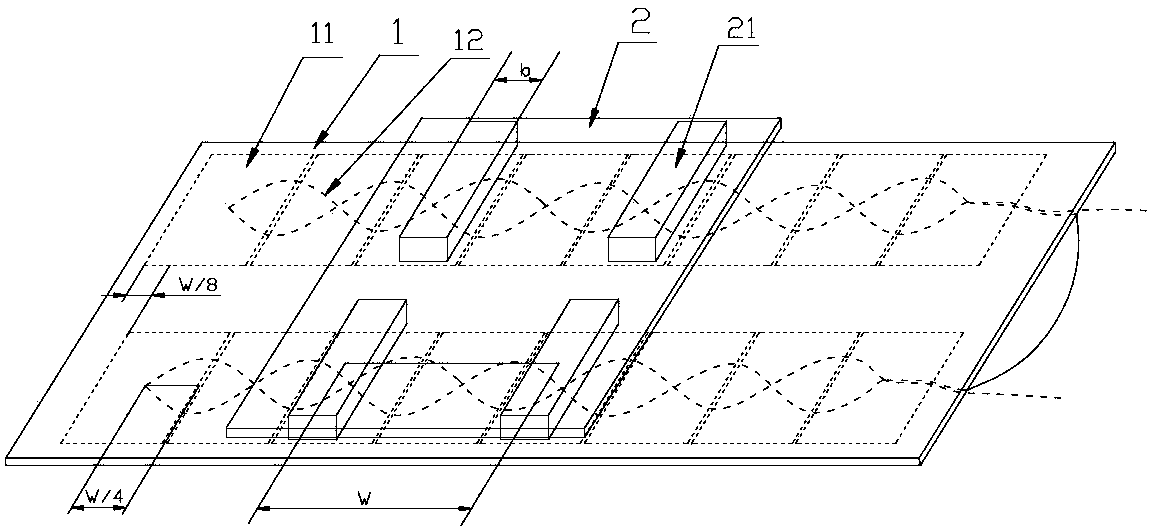

[0023] Embodiment 1: as figure 1 , Figure 4 , Figure 5 The time grating linear displacement sensor shown includes fixed scale 1 and moving scale 2.

[0024] The fixed length 1 is composed of a rectangular parallelepiped fixed length substrate and two identical and parallel sensing units arranged on the upper and lower parts of the fixed length substrate. The fixed length substrate adopts the printed circuit board substrate, and the length of the fixed length substrate is The side direction is the measurement direction, and each sensing unit includes an excitation coil 11 and an induction coil 12 .

[0025] The excitation coil 11 is composed of four positively wound planar rectangular spiral excitation coils 111 and four reversely wound planar rectangular spiral excitation coils 112 arranged alternately along the measurement direction, and arranged on the same wiring layer. The forwardly wound planar rectangular spiral excitation coils 111 and The size of the anti-winding ...

Embodiment 2

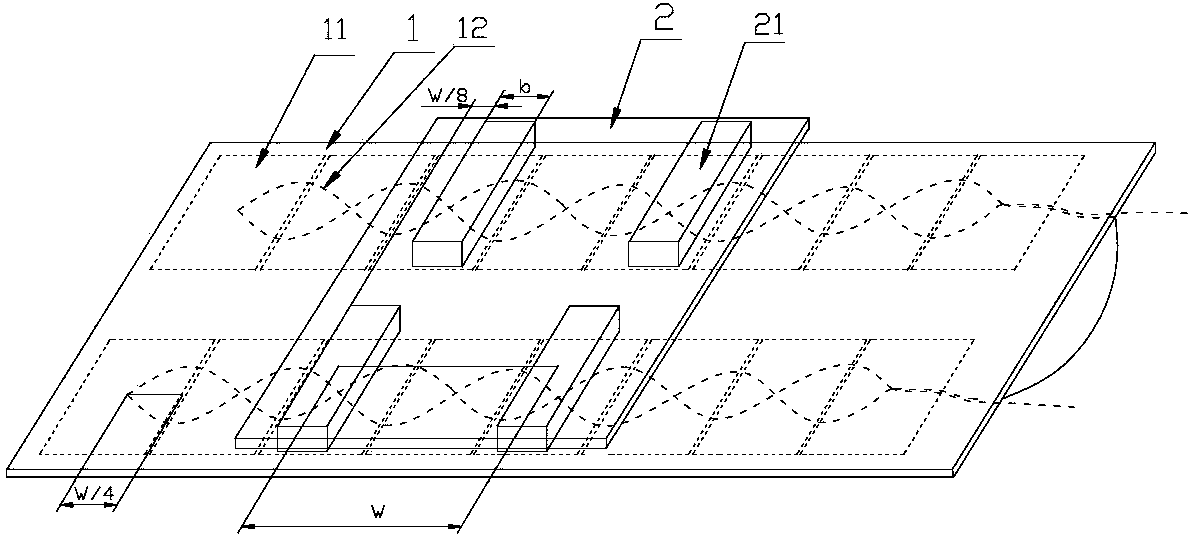

[0038] Embodiment 2: as figure 2 , Figure 4 , Figure 5 The structure of the time grating linear displacement sensor shown is mostly the same as that of Embodiment 1, except that the initial position of the sensing unit arranged on the upper part of the fixed-length base is the same as that of the sensing unit arranged on the lower part of the fixed-length base. The initial position is aligned, and the initial position of the magnetic conductor 21 embedded in the magnetic permeable unit at the upper part of the moving scale base is different from the initial position of the magnetic permeable body 21 embedded in the magnetic permeable unit at the lower part of the movable scale base

[0039] The excitation coils of the upper and lower sensing units of fixed length 1 are respectively connected with sinusoidal excitation currents with the same two-phase amplitude and a phase difference of 180°, and the induction coils of the upper and lower sensing units will respectively g...

Embodiment 3

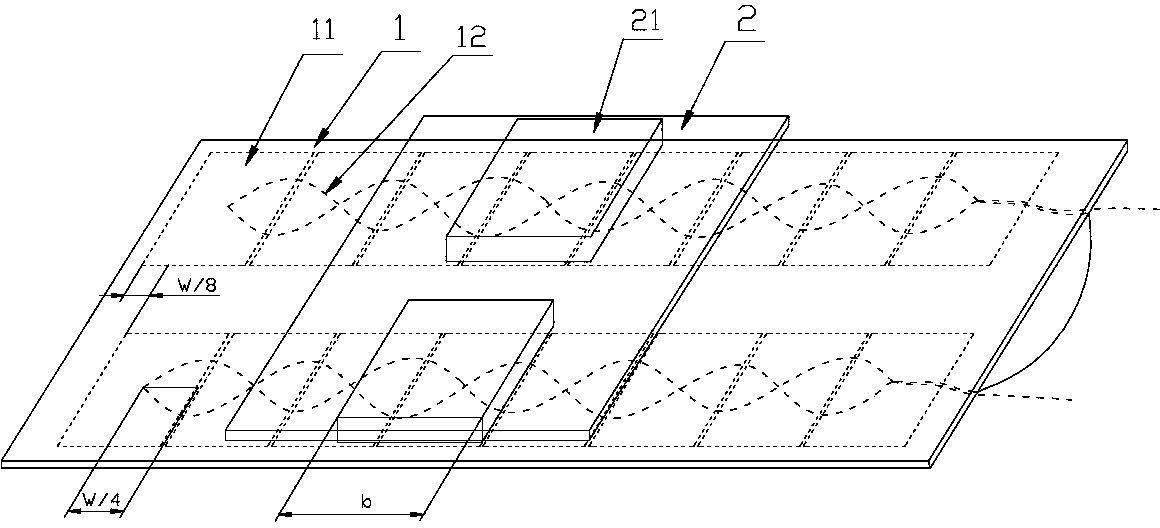

[0046] Embodiment 3: as image 3 , Figure 4 , Figure 5 The time grating linear displacement sensor shown, most of its structure is the same as that of embodiment 1, the difference is that: the magnetic conduction unit of moving ruler 2 is made of a rectangular parallelepiped magnetic conductor 21, and along the measurement direction, the magnetic conductor The width b of 21 is equal to

[0047] The excitation coils of the upper and lower sensing units of fixed length 1 are respectively connected with sinusoidal excitation currents with the same two-phase amplitude and a phase difference of 180°, and the induction coils of the upper and lower sensing units will respectively generate formula (7) And the induction signal of formula (8):

[0048] e 1 = K 3 sin 2 π t T sin ( 2 π ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com