A fuel injector that can control the timing and quantitative injection of fuel for the engine

A timed quantitative, fuel injector technology, applied in engine components, machines/engines, fuel injection devices, etc., to achieve good sealing effect, improve economy, and reduce harmful emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the scope of the described embodiments.

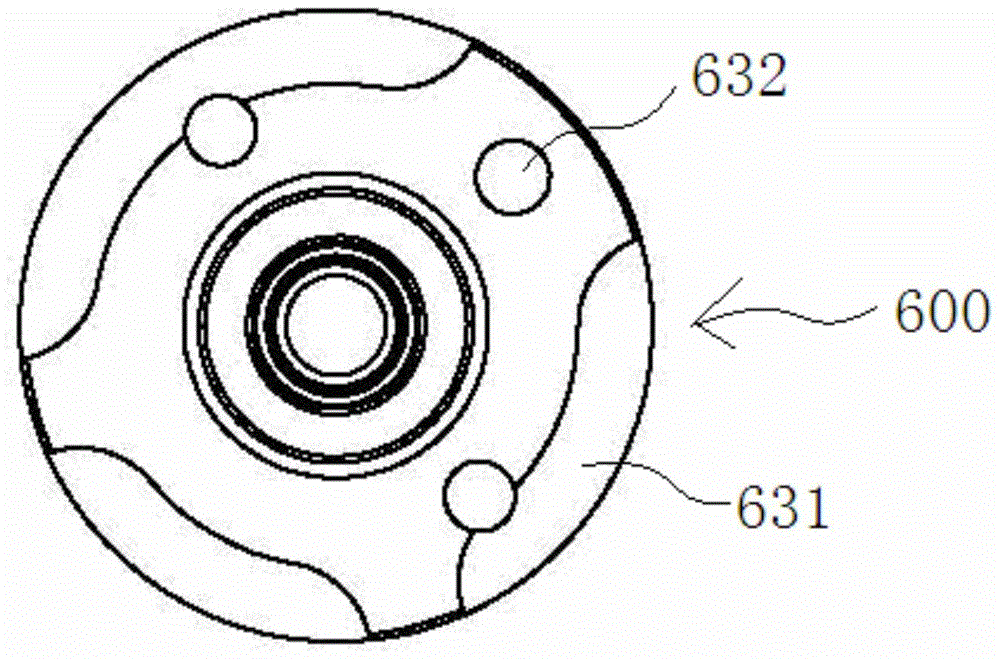

[0039] see figure 1 , a fuel injector that can be controlled to provide timing and quantitative injection of fuel for the engine is shown in the figure, including a fuel injector body 100, and in the center of the fuel injector body 100, there are steps arranged in a stepped manner from top to bottom. coaxial mounting holes 111, 112, 113, 114, and an oil distribution hole 120 parallel to the coaxial axis of the mounting holes 111, 112, 113, 114 is also provided in the injector body 100, and the oil distribution hole 120 is axially penetrating through the entire fuel injector body 100 . In addition, a high-pressure oil inlet joint installation hole 131 and an oil inlet hole 132 are arranged at the upper position of the middle part of the injector body 100. The high-press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com