Short intelligent-control hoist type lifting oil extraction system with ultra long stroke and working method

An ultra-long stroke, intelligent control technology, applied in the fields of fluid production, earth drilling, wellbore/well components, etc., which can solve the problems of high tubing processing cost, many consumables, and inconvenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

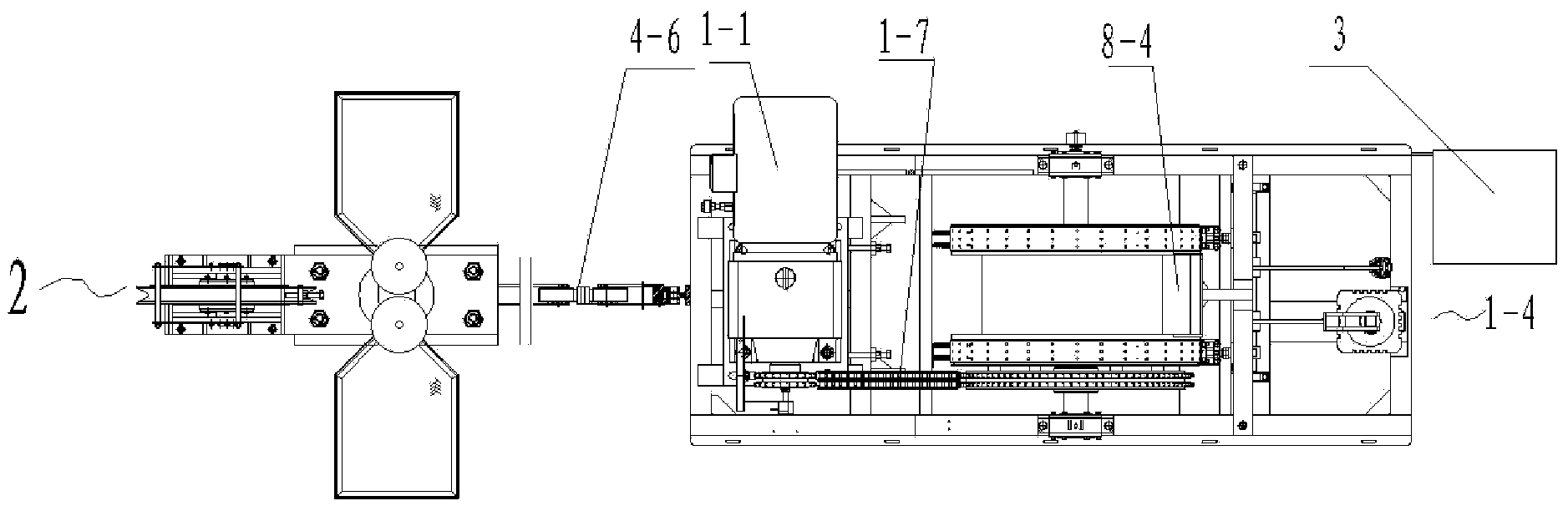

[0074] see figure 1 , figure 2 As shown in Fig. 5, a low-slung ultra-long-stroke intelligently controlled hoisting oil recovery system of the present invention includes: a power drive assembly 1, a fixed pulley assembly 2, a control assembly 3, a derrick assembly 4, and a sliding swing device 5. Rope pressure device 8, wellhead device 6, downhole pipe string 9, flexible oil rope 11, steel wire rope or sucker rod 10, and downhole multi-stage plunger ultra-long stroke oil well pump 7; power drive assembly 1 includes gear motor 1 -1, reel 1-2, brake assembly 1-4, the structure is: sprocket 1-3 and encoder 3-1 are housed on the output shaft of reduction motor 1-1; Reel sprocket 1- is housed on the shaft The drum 1-2 of 5 is installed on the drum base 1-6, and the drum base 1-6, the reduction motor 1-1, the brake assembly 1-4 are fixed on the ground base 1-8; the drum sprocket 1-5 and the sprocket 1-3 are located in the same plane and connected by the transmission chain 1-7;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com