Multistage plunger super-long-stroke oil well pump

An ultra-long stroke, multi-stage column technology, applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of easy resistance, no development, discomfort of rod pumping units, etc., to reduce wear, Small gap, solve the effect of plunger stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

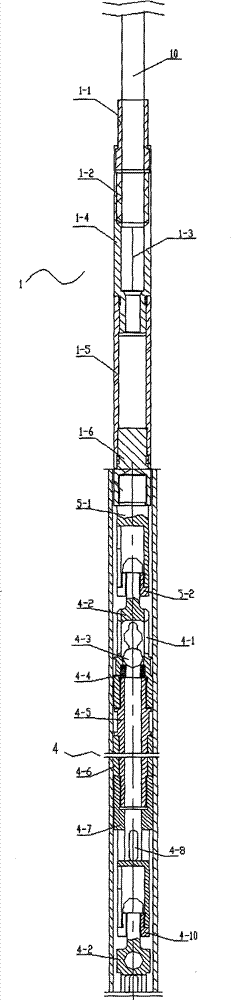

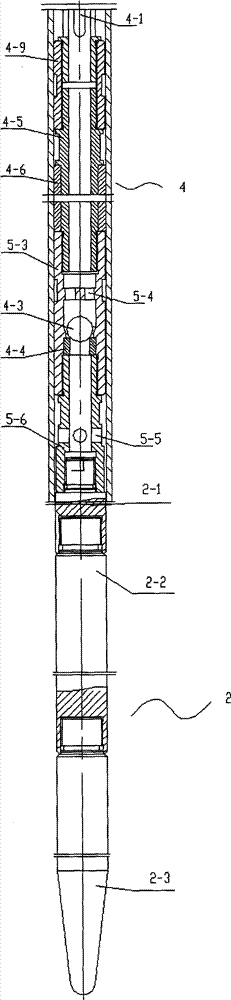

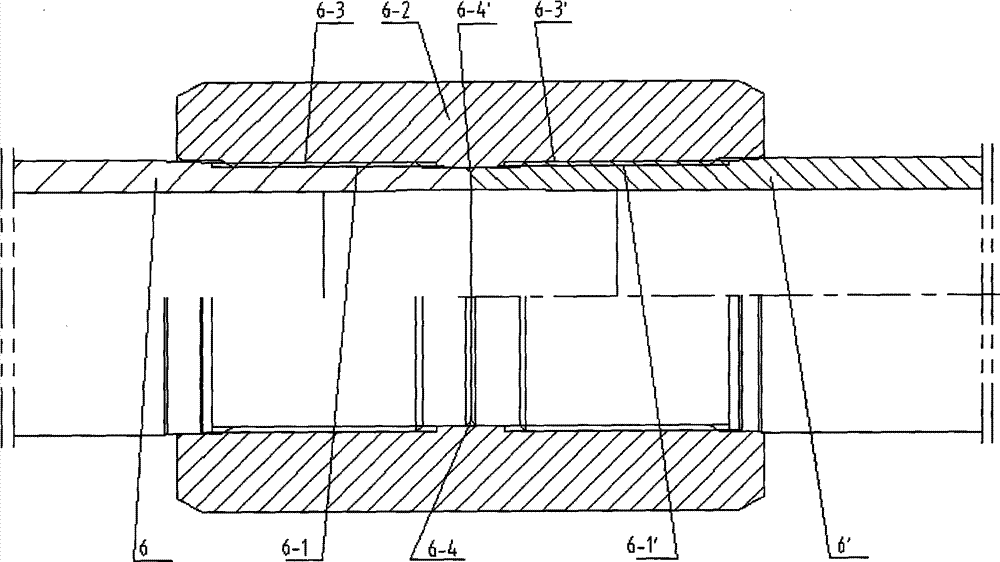

[0014] see Picture 1-1 , Figure 1-2 , image 3 , a multi-stage plunger ultra-long stroke oil well pump is composed of a steel body multi-stage plunger 9 and an ultra-long pump barrel 11; the steel body multi-stage plunger 9 is placed in the ultra-long pump barrel 11; the steel body multi-stage plunger 9 is composed of a sealing cavity part 1, a weight part 2 and a plurality of steel-body single-stage plungers 4 connected in series; a sealing gland 1-1, a sealing glue 1-2 and a pressure rope head 1-3 seal the wire rope 10 The upper section 1-4 of the chamber is compressed, the sealing gland 1-1, the upper section 1-4 of the sealing chamber, the sealing chamber 1-5, and the upper variable diameter 1-6 are threaded in turn, and the sealing ring is sealed to form the seal of the plunger. Cavity part 1; the number of serially connected weighting rods 2-2 is determined by the need for counterweight, and the lower variable diameter 2-1, multiple weighting rods 2-2, and the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com