High-content steel slag grouting material

A grouting material with a large amount of mixing technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of low interface strength and poor durability, and achieve good fluidity, high strength, steel slag mixed The effect of a large amount of input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

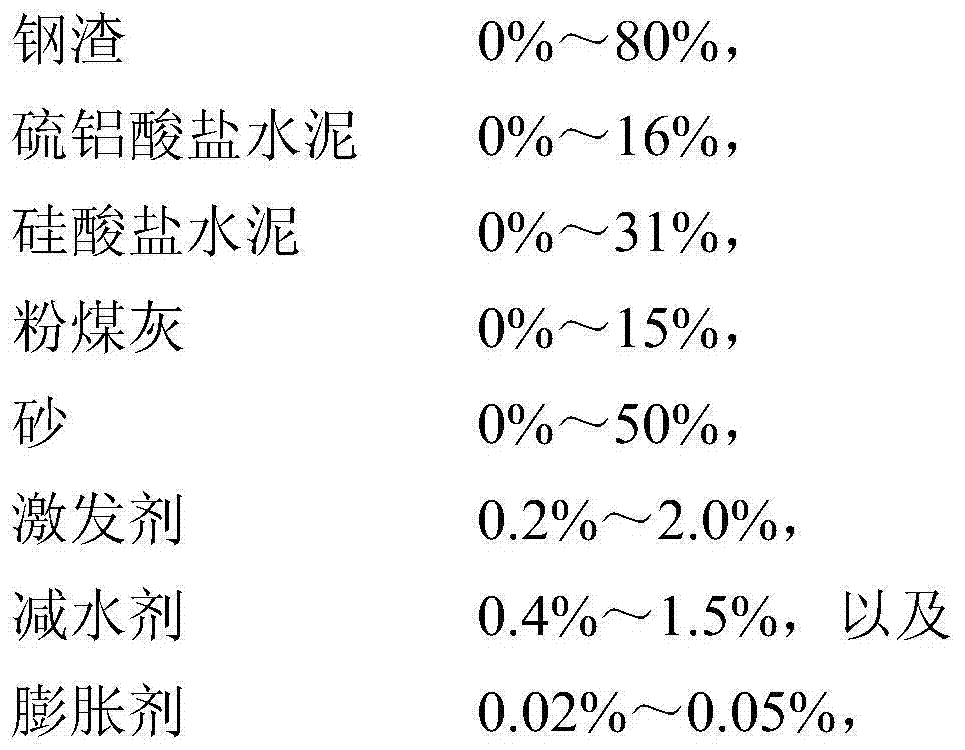

[0039] Each component is uniformly mixed according to the following ratio to prepare the large-volume steel slag grouting material of the present invention:

[0040]

Embodiment 2

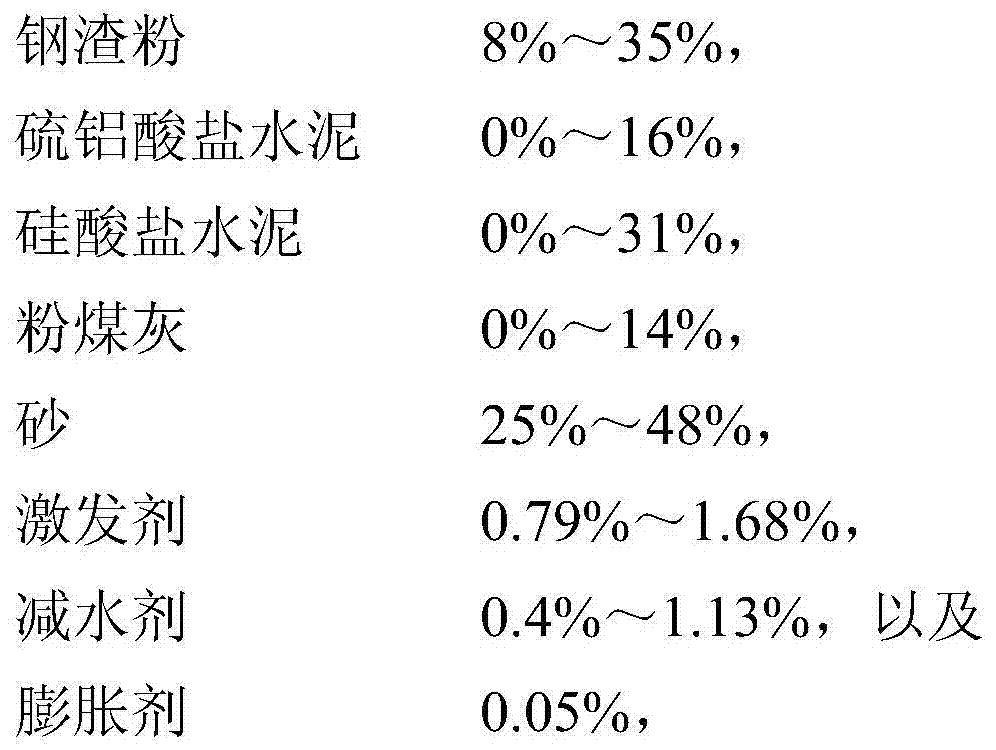

[0042] Each component is uniformly mixed according to the following ratio to prepare the large-volume steel slag grouting material of the present invention:

[0043]

[0044]

[0045] The large-volume steel slag grouting material prepared in Example 2 has a steel slag content as high as 79.6%, but its performance indicators meet the requirements of the "Technical Specifications for the Application of Cement-Based Grouting Materials" GB / T50448-2008. Fluidity can reach 330mm, compressive strength 1d≥40MPa, 3d≥50MPa, 28d≥62MPa.

Embodiment 3

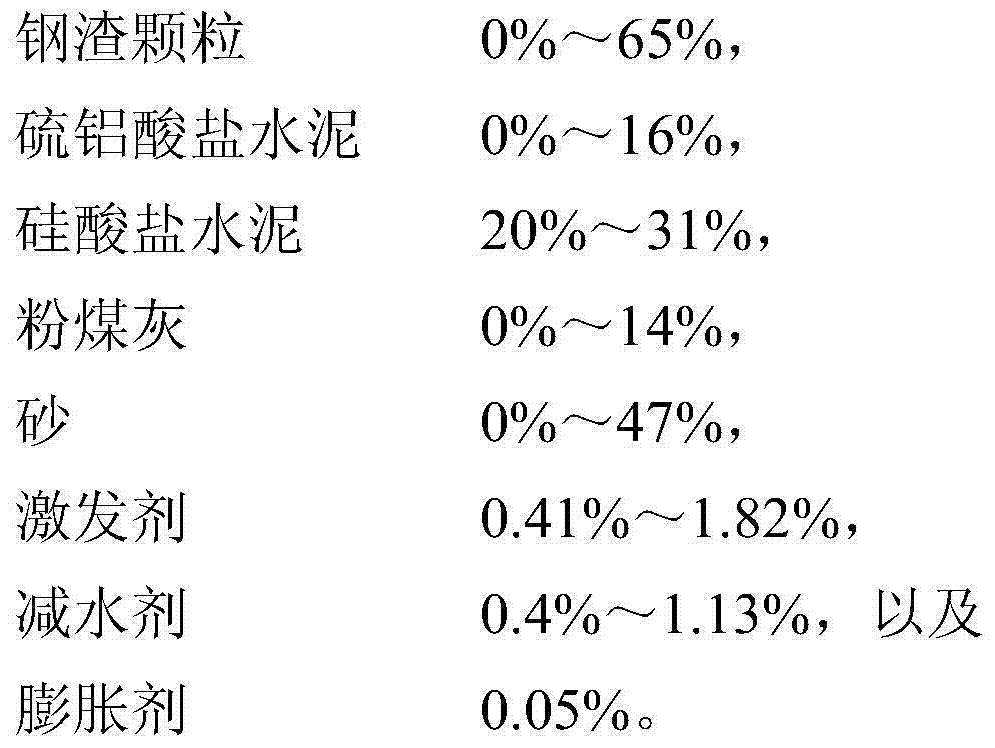

[0047] Each component is uniformly mixed according to the following ratio to prepare the large-volume steel slag grouting material of the present invention:

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com