Production technology of 'zero-carbon emission' cement combined with industrial gypsum waste treatment

A technology for industrial waste gypsum and industrial gypsum, which is applied in the fields of waste treatment and utilization and environmental protection, can solve the problems of occupying land resources, high economic benefits, low process costs, etc., and achieves low process costs, high economic benefits, and reduced CO2 emissions. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

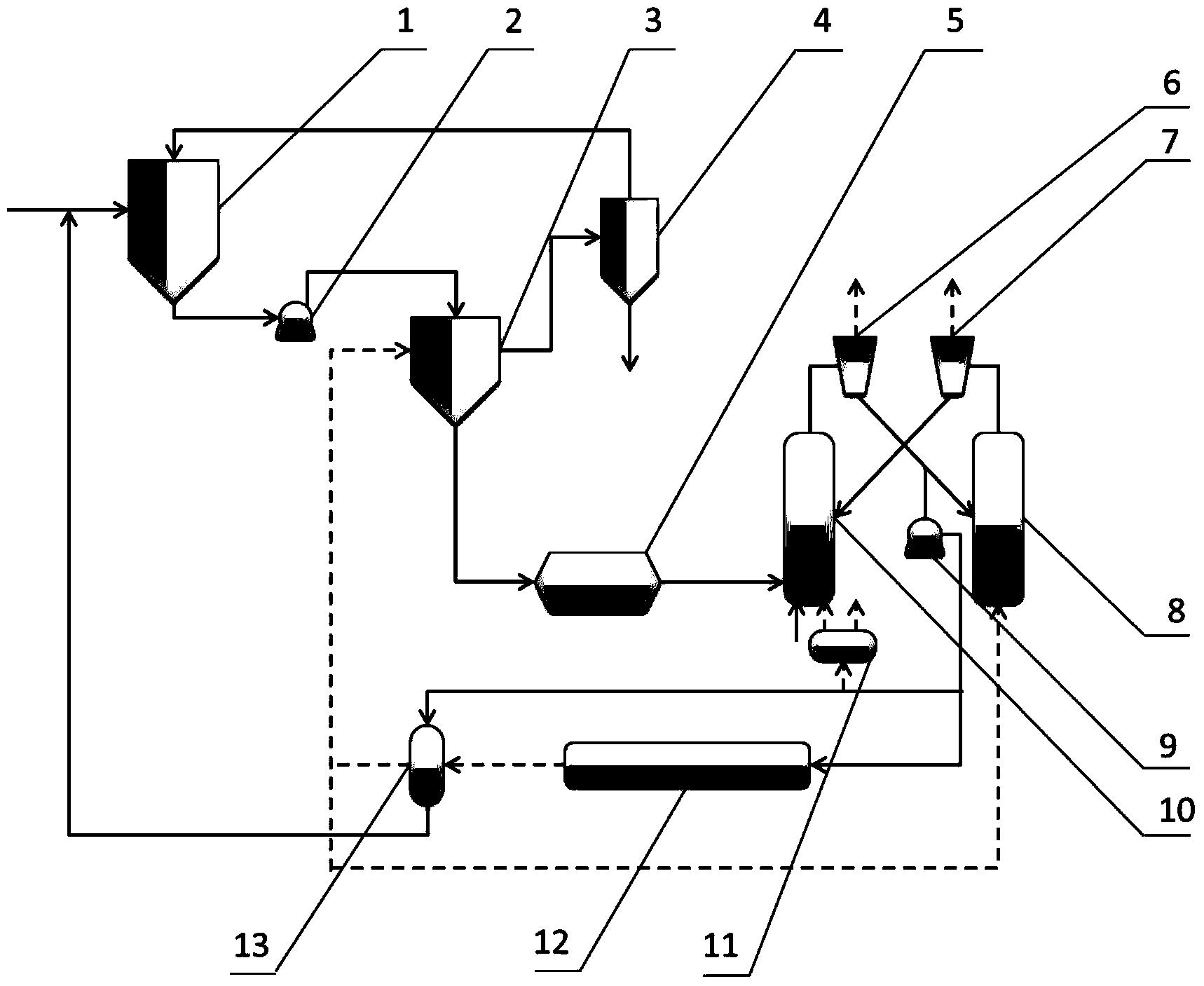

[0024] Attached below figure 1 The present invention is described in detail.

[0025] refer to figure 1 , this embodiment includes the following systems: industrial gypsum waste carbonation treatment system, obtained calcium carbonate molding processing system, calcium cycle CO 2 Capture systems, cement production systems. The gypsum waste from the industrial production process is fully mixed with a certain amount of water and ammonia solution in the slurry tank 1, and is transported to the carbonation tank 3 through the material pump 2 for carbonation with part of the desulfurized cement kiln tail gas. reaction, the main component obtained is CaCO 3 The solid product mixed with an appropriate amount of cement is sent to the particle forming machine 5 for molding processing, and the upper solution in the carbonation tank 3 is sent to the crystallization tank 4, and the ammonium sulfate obtained by crystallization can be used as agricultural fertilizer, and the excess ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com