Regeneration field mixed asphalt and preparation method thereof

A kind of asphalt and waste asphalt technology, which is applied in the field of asphalt mixing and its preparation in the recycling field, can solve the problems of low cost and pollution of milling asphalt waste stacking, achieve low cost, realize regeneration and recycling, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

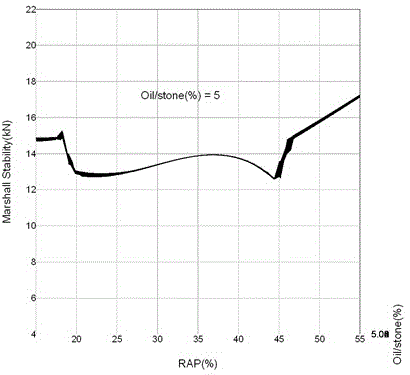

Embodiment 1

[0033] Example 1: A kind of mixed asphalt in a recycling plant, the percentage of each raw material is: waste asphalt pavement material 15.00%, new aggregate 85.00%, oil stone ratio 4.32%, mineral powder 5.25%, crude oil 11.34%, catalytic cracking slurry 9.04, 12.00% lubricant dispersant. The Marshall stability in the air is 17.12kN, and the flow value is 2.71mm.

Embodiment 2

[0034] Example 2: A kind of mixed asphalt in a recycling plant, the percentages of each raw material are: waste asphalt pavement material 25.35%, new aggregate 74.65%, oil stone ratio 6.68%, mineral powder 7.36%, crude oil 10.86%, catalytic cracking slurry 10.00%, lubricant dispersant 10.45%. The Marshall stability in the air is 16.08kN, and the flow value is 2.32mm.

Embodiment 3

[0035] Example 3: A kind of mixed asphalt in a recycling plant, the percentage of each raw material is: waste asphalt pavement material 21.06%, new aggregate 78.94%, oil stone ratio 5.21%, mineral powder 6.79%, crude oil 20.00%, catalytic cracking slurry 5.90%, lubricating oil dispersant 10.76%. The Marshall stability in the air is 12.51kN, and the flow value is 2.38mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com