Method for treating heavy metal wastewater by superconductive HGMS (high gradient magnetic separation)-FeOOH coupled technique

A heavy metal and waste water technology, applied in the field of resources and environment, can solve the problems of high consumption and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

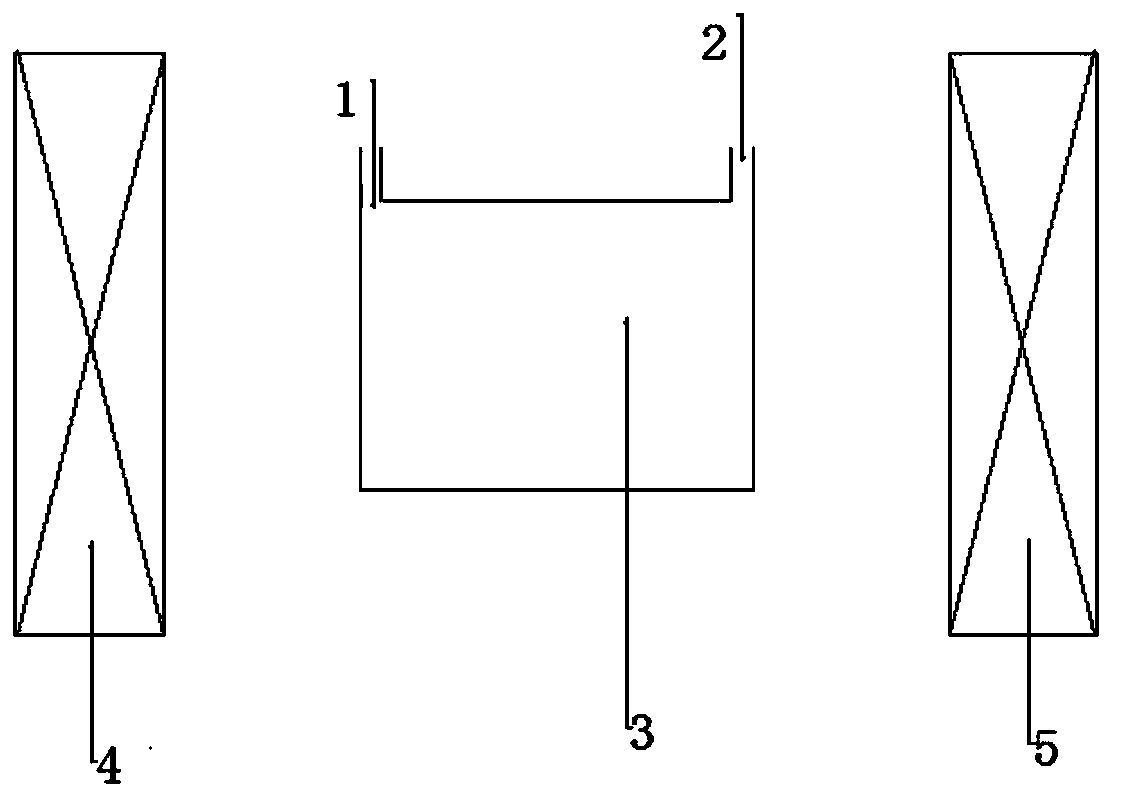

Method used

Image

Examples

Embodiment 1

[0024] Take a certain amount of heavy metal wastewater, add 0.1g / ml FeOOH, inject it into the reaction tank of the magnetic field through the peristaltic pump with flow control, and let it stand in the 5T magnetic field for 3 minutes. The diameter of the reaction tank d / the distance i between the magnetic field generator and the reaction tank wall is 5. Measure the arsenic ion concentration in the treated water sample. The concentration of arsenic particles after treatment was 3506.5mL / L, reaching 29.03%.

Embodiment 2

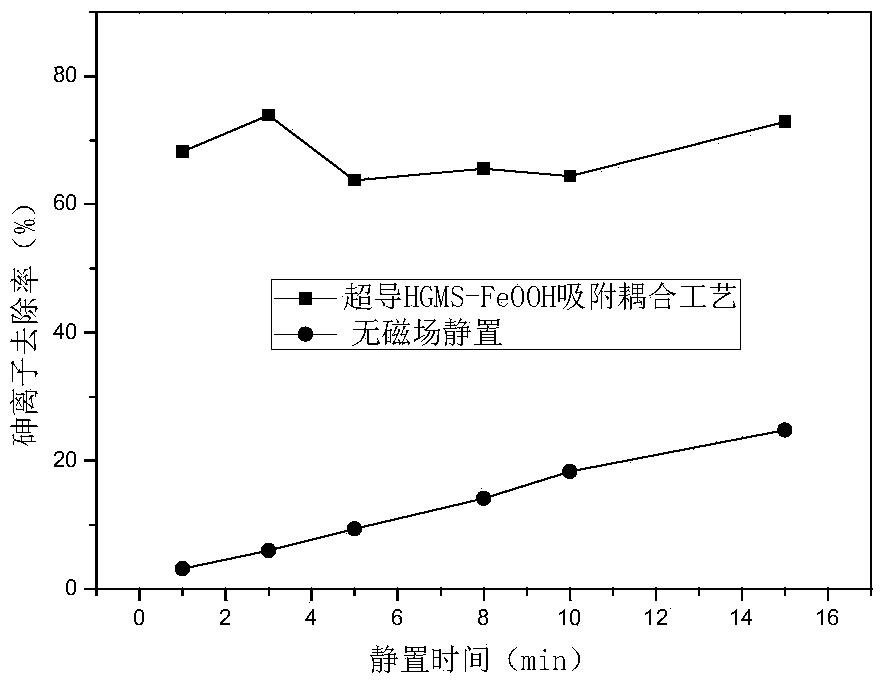

[0026] Take a certain amount of heavy metal wastewater, add 0.6g / ml FeOOH, inject it into the reaction tank of the magnetic field through the peristaltic pump with flow control, and let it stand in the 5T magnetic field for 15 minutes. The diameter of the reaction tank d / the distance i between the magnetic field generator and the reaction tank wall is 3. Measure the arsenic ion concentration in the treated water sample. After treatment, the concentration of arsenic particles was 1130.3mL / L, reaching the best 77.12% (such as figure 2 shown).

Embodiment 3

[0028] Take a certain amount of heavy metal wastewater, add 0.8g / ml FeOOH, inject it into the reaction tank of the magnetic field through the peristaltic pump with flow control, and let it stand in the 5T magnetic field for 8 minutes. The diameter of the reaction tank d / the distance i between the magnetic field generator and the reaction tank wall is 4. Measure the concentration of arsenic ions in the treated water samples. The concentration of arsenic particles after treatment was 1284.6mL / L, reaching 74%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com