Control valve, hydraulic control system of winch brake and crane

A technology of hydraulic control system and control valve, applied in the field of hydraulic control system and crane, can solve the problems of secondary sliding of heavy objects and insufficient motor establishment, so as to avoid the hoisting and sliding, alleviate the hoisting and lifting jitter, and prolong the The effect of opening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The core of the present invention is to provide a hydraulic control system for a control valve and a hoist brake, and a crane. The hydraulic control system with the control valve can effectively avoid hoist vibration when controlling the hoist brake.

[0041] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

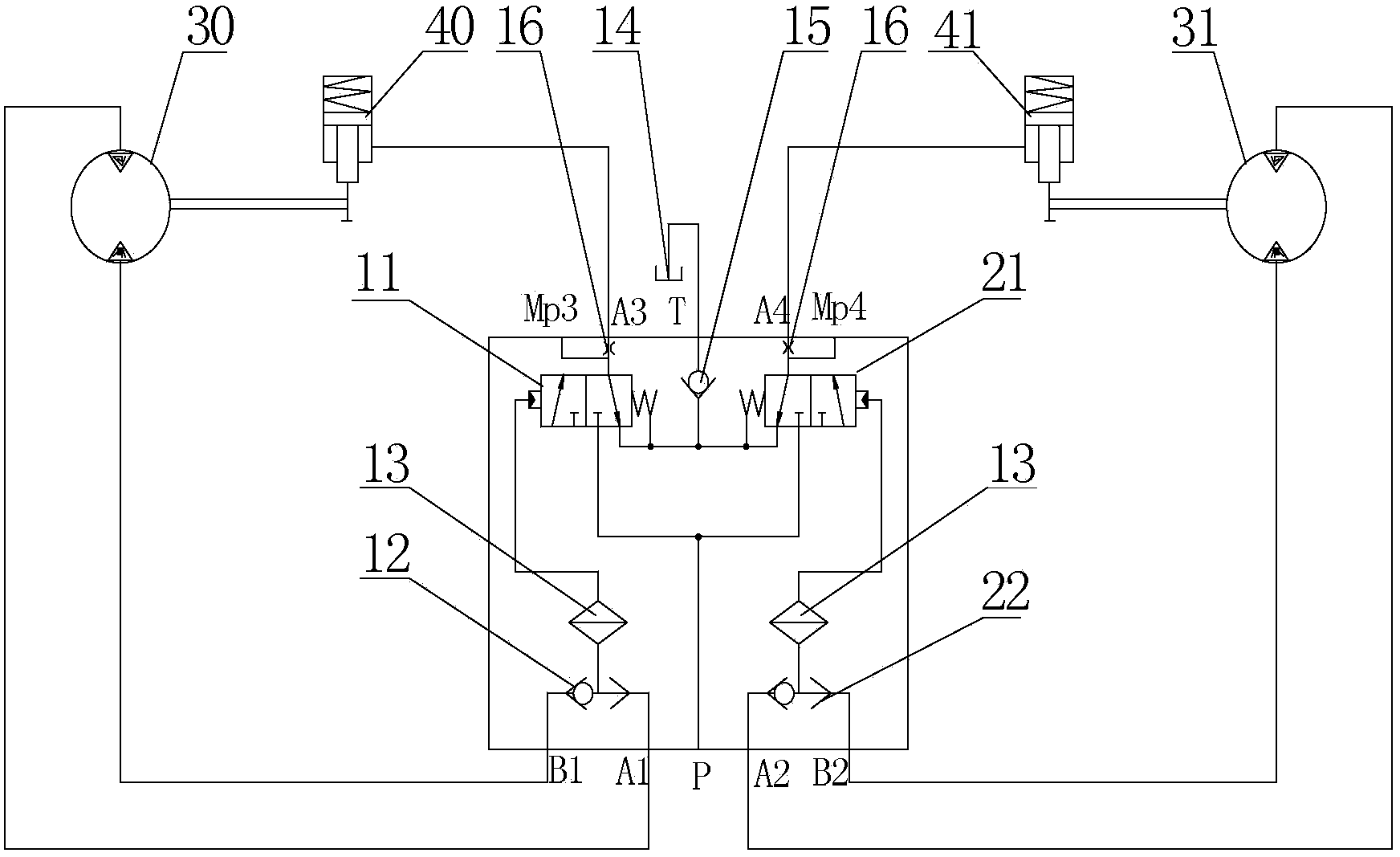

[0042] Please refer to figure 2 , figure 2 It is a schematic diagram of the working principle of the control valve in the first embodiment of the present invention.

[0043]The present invention provides a control valve for hoist brake, which includes a valve body, a first reversing valve 11 is integrated in the valve body, and a first oil port P, a second oil port T and a third oil port are arranged outside the valve body. Port A3; the first oil port P is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com