Guide barrel constitutive structure used for installation of tread brake

A tread brake and guide cylinder technology, which is applied in locomotive design and manufacturing fields, can solve problems such as the side beam structure is greatly affected, and the installation structure is complicated to bear the force, so as to ensure the installation space and reduce the shear force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

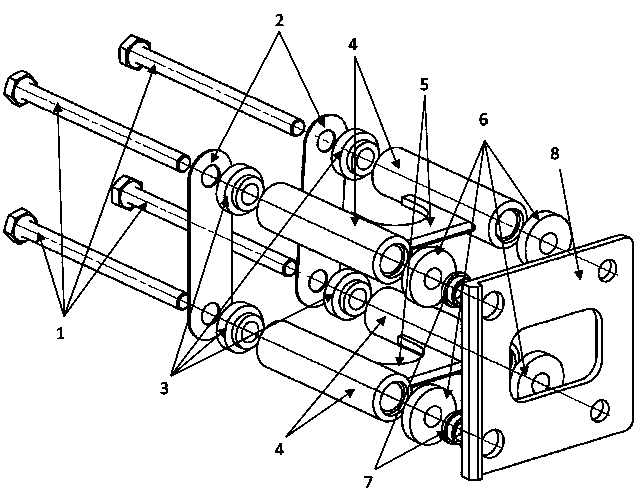

[0018] A guide cylinder composition structure for tread brake installation, such as figure 1 As shown, the structure of the guide cylinder is connected with the frame side beam vertical plate through the guide cylinder 4, and connected with the tread brake through the bolt 1. The outer socket 3 and the inner socket 6 are respectively installed on both sides of the guide cylinder, and the outer safety gasket 2 is passed through The bolt 1 is connected with the outer socket 3 and the guide cylinder 4, the inner safety gasket 8 is connected with the inner socket 6 and the guide cylinder 4 through the bolt 1, and a fastening pin 7 is installed at the far end of the inner safety gasket 8 .

[0019] The above-mentioned embodiments should be understood that these embodiments are only used to illustrate the present invention more clearly, and are not intended to limit the scope of the present invention. After reading the present invention, those skilled in the art will understand the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com