A double-gun co-spray composite film preparation process based on immiscible functional materials

A technology for composite films and functional materials, which is applied in spraying devices, liquid spraying devices, and devices for coating liquids on surfaces, etc., can solve the problems such as the inability to prepare mixed composite films, and achieve the realization of film fineness, process simplicity, experimental The effect of high success rate and low cost requirements

Active Publication Date: 2015-09-30

UNIV OF ELECTRONICS SCI & TECH OF CHINA

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The purpose of the present invention is to provide a process for preparing non-miscible material mixed composite films to solve the problem that mixed composite films cannot be prepared in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

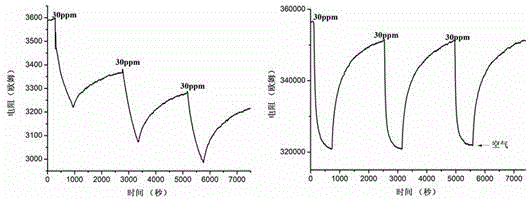

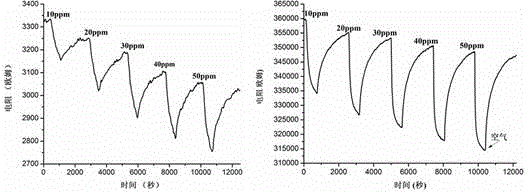

[0029] A composite film gas sensor of graphene aqueous solution and 3-hexylthiophene polymer (P3HT) chloroform solution was prepared by co-spraying method. A graphene aqueous solution with a concentration of 1 mg / ml and a P3HT chloroform solution with a concentration of 3 mg / ml were used.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

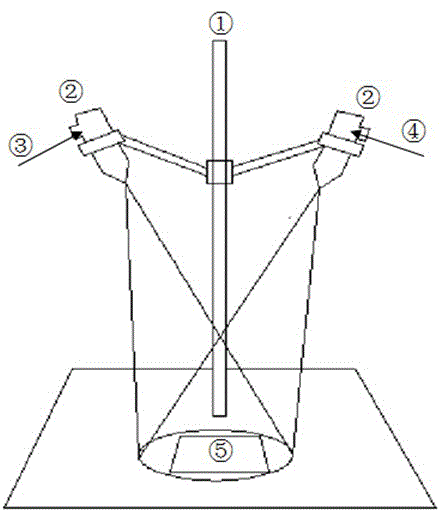

The invention discloses a double-gun jointly spraying composite film preparation technology based on immiscible function materials. Immiscible film material liquids are sprayed to the surface of the same target device by different spray guns respectively to form a composite film. The composite film preparation technology based on two immiscible function materials has the advantages that organic and inorganic materials which cannot be composited into a film with a conventional technology of film formation from solutions can be combined in a standard gaseous state and a dispersed state, so that an organic and inorganic material composite film is formed through deposition. The method can be used for preparing the organic and inorganic material composite film and can also be used for ordinary film formation, large-area film formation, film formation of a device with a complicated structure, film formation of a flexible material and various film formation forms such as chemical reaction film formation, physical deposition film formation and the like.

Description

technical field [0001] The invention relates to the field of thin film preparation technology, in particular to the thin film preparation technology of organic-inorganic composite materials. Background technique [0002] With the miniaturization, convenience and industrialization of electronic devices, thin film materials have become a trend in the preparation and application of electronic devices. Thin film materials are characterized by lightness, quickness and less consumables, and can be widely used in various fields, which is the trend of material development. With the development of thin-film materials, thin-film film-forming technology has become an important topic in the development of thin-film materials. Due to different material characteristics and device requirements, various thin-film film-forming processes have emerged. Each film-forming process has its own advantages. Each has its own characteristics and has made considerable progress in its respective fields...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B05B9/04B05B12/00B05B15/10B05D3/00

CPCB05D1/02B05D1/34

Inventor 太惠玲叶宗标袁震何应飞谢光忠蒋亚东

Owner UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com