Application of compound type D-class dry powder extinguishing agent in fire disaster of lithium metal and derivative thereof

A dry powder fire extinguishing agent, composite technology, applied in fire protection equipment and other directions, can solve the problems of poor operability, scarcity of fire extinguishing agent, poor fire extinguishing effect, etc., and achieve the effect of fast fire extinguishing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

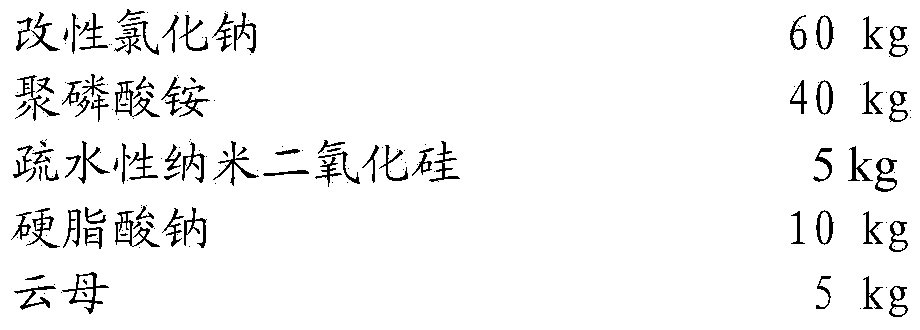

[0046] Raw material consumption

[0047]

[0048] The modified sodium chloride used is commercially available and is made of nano-SiO 2 Particles and surfactant F127 are coated with modified non-agglomerated sodium chloride particles, the core layer is sodium chloride particles with a particle size of 25-30 μm, and the coat layer is a coating material with a thickness of 5-200 nm; after modification, chlorine The monodispersity and fluidity of sodium chloride particles become better, the flow rate reaches 4-6mL / s, and the bulk density increases to 0.6-0.8g / cm 3 , decreased hygroscopicity. SEM, FT-IR, and hygroscopicity tests show that this preparation method improves the surface properties of NaCl particles, can effectively reduce its hygroscopicity and hard agglomeration, and improve fluidity and dispersion.

[0049] The ammonium polyphosphate used is commercially available, and the degree of polymerization n=1000 or more;

[0050] The hydrophobic silica used is commercia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com