Superconducting wire

A technology of superconducting wires and oxide superconducting layers, applied in the field of superconducting wires, can solve the problems of rising manufacturing costs and lowering yield of superconducting wires, and achieve the effects of high critical current, good surface smoothness, and high adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

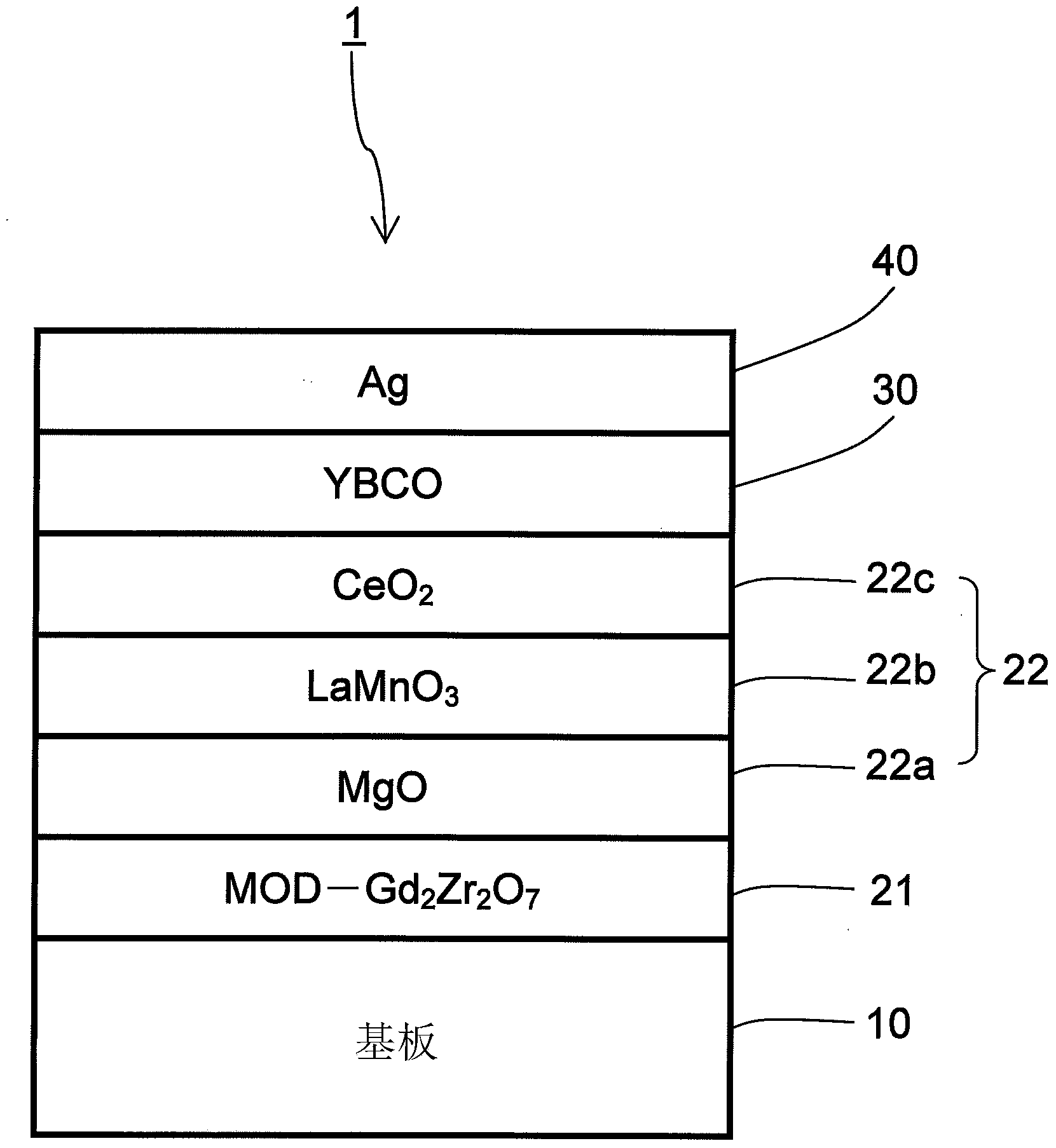

[0056] In order to study the maximum contour height Rz of the film-forming surface of the substrate 10, the arithmetic mean roughness Ra of the surface of the first intermediate layer 21, the adhesion strength between the first intermediate layer 21 and the substrate 10, and the critical current Ic of the superconducting wire 1 A plurality of samples of the superconducting wire 1 shown in Table 1 were fabricated.

[0057] [Table 1]

[0058]

[0059] >

[0060] The substrate 10 of these superconducting wires 1 was formed by rolling Hastelloy C-276 (registered trademark) to a width of 1 cm and a thickness of 0.1 mm. The maximum contour height Rz of the film-forming surface of the substrate 10 is summarized to 6nm-18nm (6nm, 9nm, 11nm, 14nm, 18nm) by selecting the surface roughness (for example, arithmetic mean roughness Ra) of the rolling roll, etc. Go to 5 groups of ).

[0061] The measurement of the maximum profile height Rz was performed in an area of X×Y=1.54 μm×1.54...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com