Load driving device

A load-driven and pulse-driven technology, which is applied to measuring devices, logic circuit connections/interface layouts, instruments, etc., can solve problems such as pulse drive circuit failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

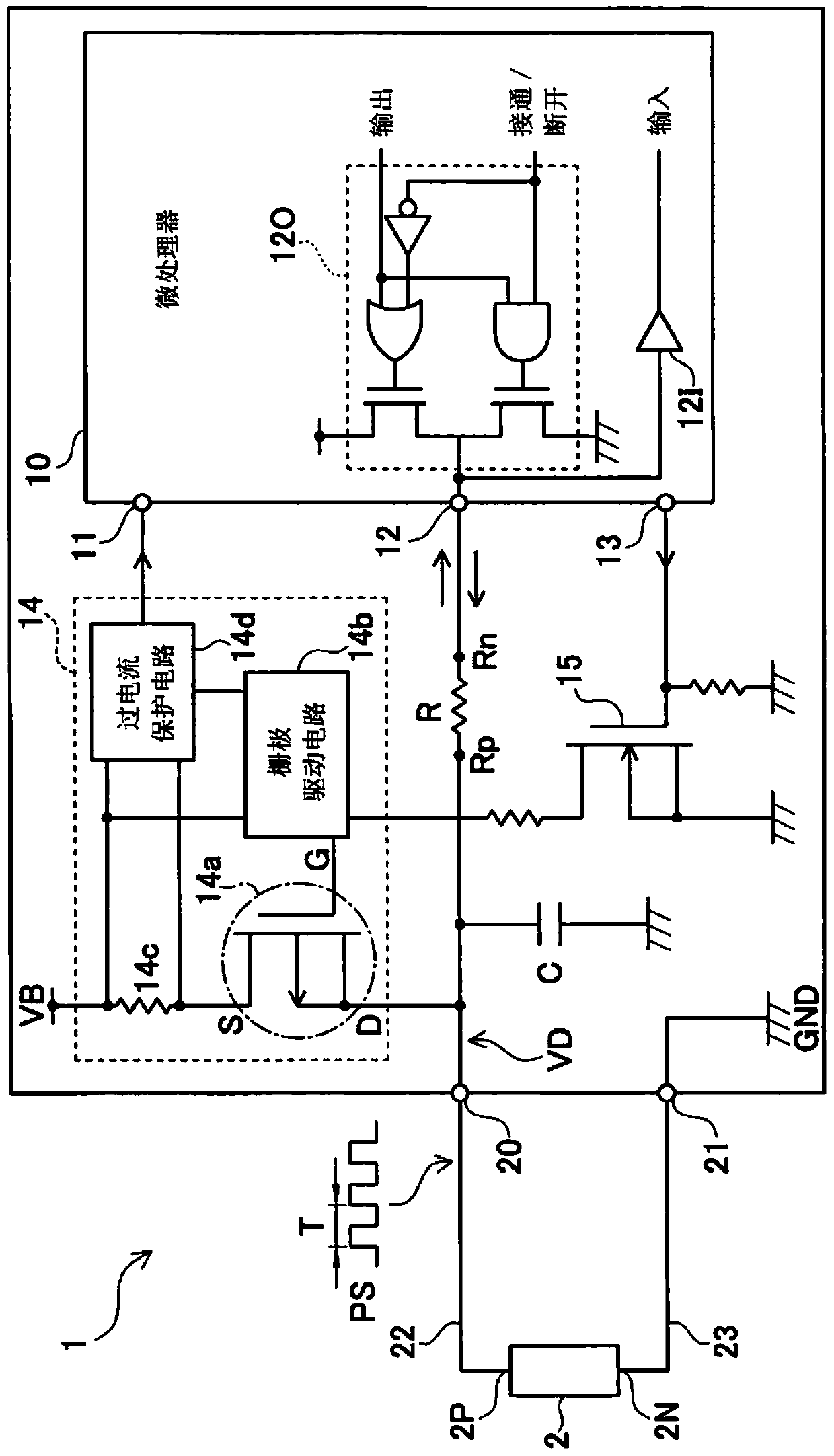

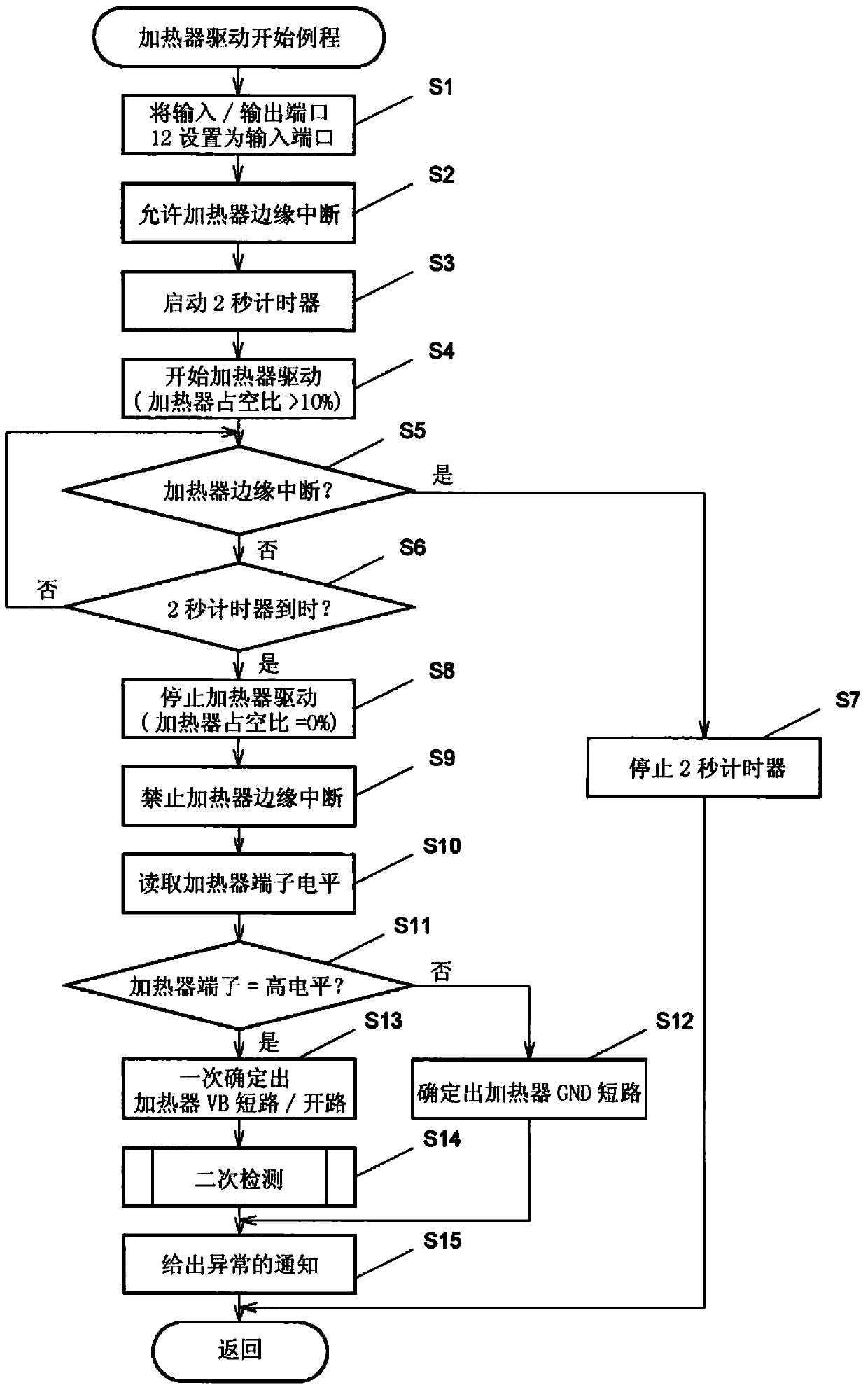

[0035] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It is a figure which shows the schematic structure of the load drive apparatus 1 of this embodiment. The load driving device 1 drives a resistive load, and in this embodiment, the use of the load driving device 1 to drive a detection element (not shown) for an oxygen sensor mainly made of a solid electrolyte body such as zirconia is exemplified. The case of heater 2 for heating. Descriptions for the oxygen sensor and detection elements will be omitted.

[0036] The load driving device 1 includes a microprocessor 10 , a pulse driving circuit 14 , an FET 15 , a resistor R, and the like, and is used to drive the heater 2 .

[0037] One end 2N of the heater 2 is connected to the ground terminal 21 via the lead wire 23 , and the ground terminal 21 is grounded to the ground potential GND within the circuit of the load driving device 1 . The other end 2P of the heater 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com