A solar energy assembly with double-layer protective films

A solar module and protective film technology, which is applied in the field of solar modules, can solve the problems of low recombination rate and reduced lifespan of minority carriers on the surface of silicon wafers, and achieve the effects of high conversion efficiency, optimized graphic design, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

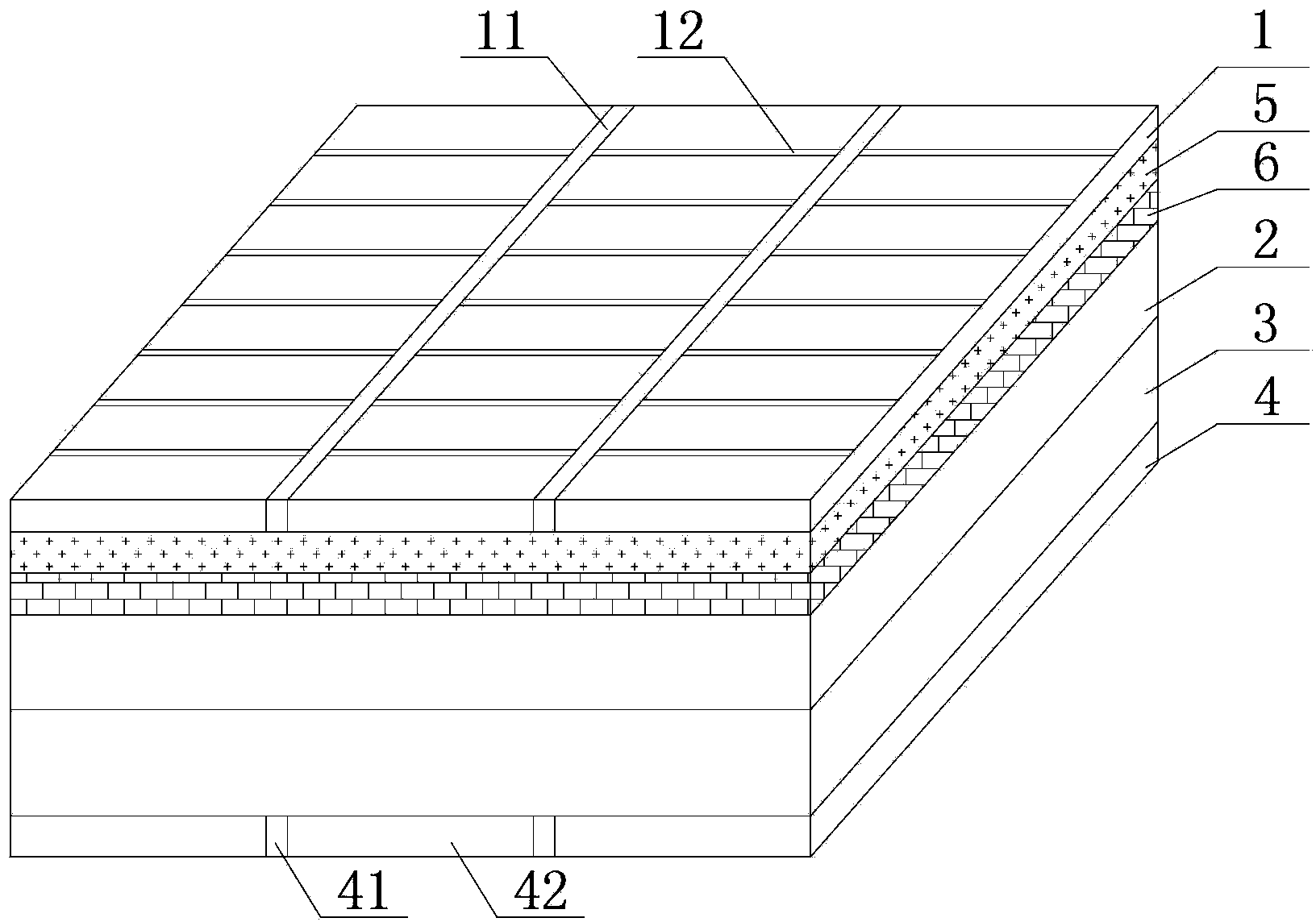

[0017] See figure 1 , the present invention has a negative electrode layer 1, an N-type silicon layer 2, a P-type silicon layer 3, a positive electrode layer 4, an anti-reflection film layer 5 and a passivation film layer 6 stacked in sequence; the negative electrode layer 1 and the positive electrode 4 are both silver layers, A main grid 11 formed by screen pattern printing and sub-grids 12 perpendicular to the main grid 11 and equally spaced are provided on the surface of the negative electrode layer 1 ; a back electrode 41 and a back electric field 42 are provided on the positive electrode layer 4 . The anti-reflection film layer 5 is a silicon nitride layer, and the anti-reflection film layer 5 is arranged between the negative electrode layer 1 and the N-type silicon layer 2; the passivation film layer 6 is a silicon dioxide layer, and the passivation film layer 6 is arranged on the anti-reflection layer. Between the membrane layer 5 and the N-type silicon layer 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com