Aircraft structural strength test loading level

A strength test and aircraft structure technology, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve problems such as torsional instability, uneven force on connecting cables, and reduced bearing capacity, so as to increase the turning radius and practicability Strong, avoid bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment carry out further description:

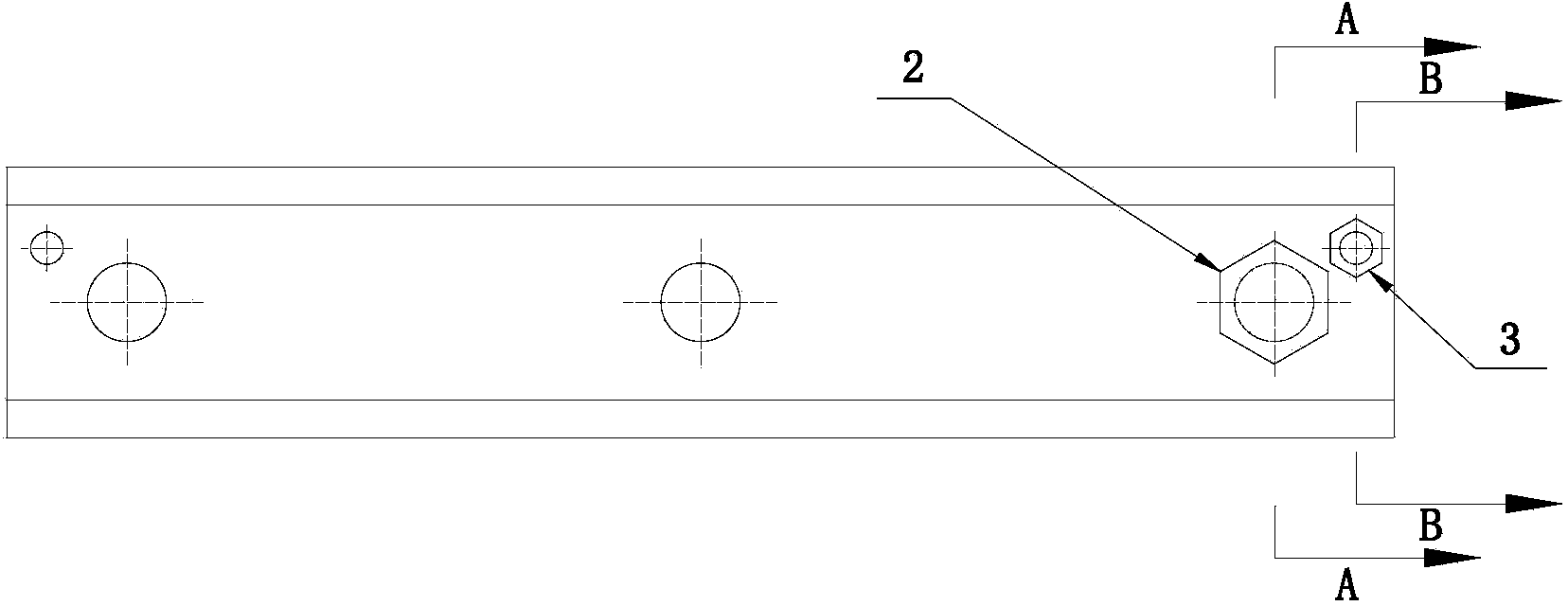

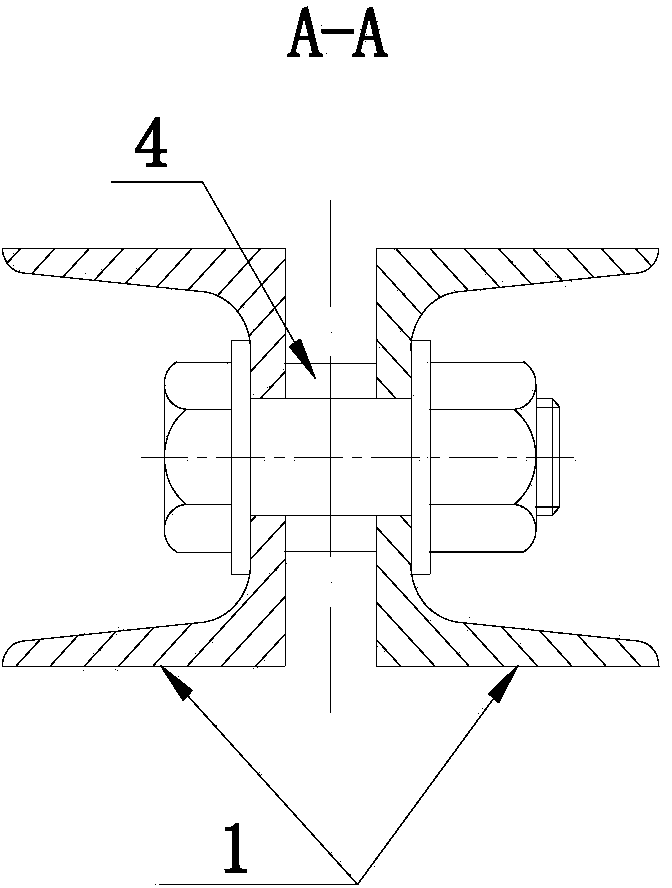

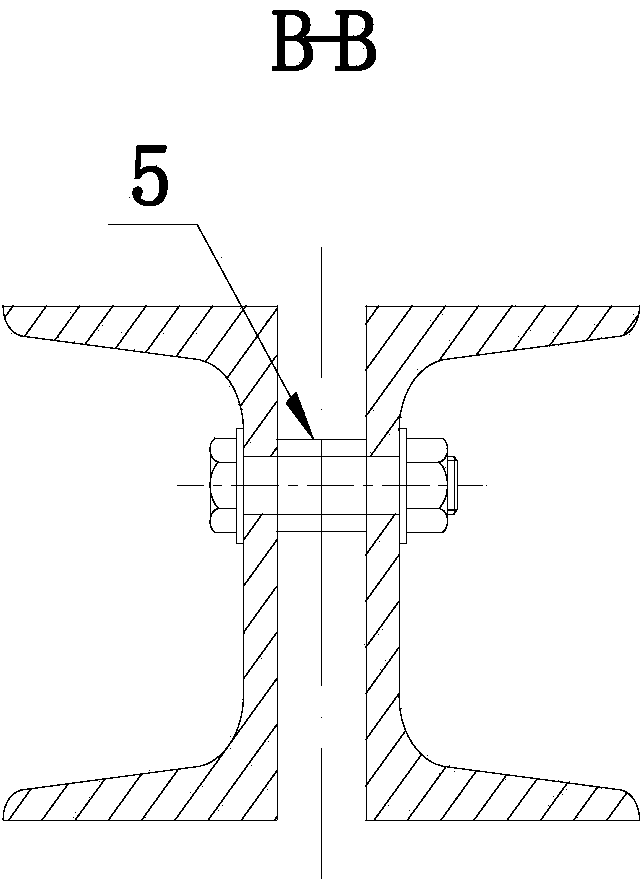

[0020] Please also see figure 1 , figure 2 , image 3 ,in, figure 1 It is a structural schematic diagram of the loading lever of the aircraft structure strength test of the present invention, figure 2 yes figure 1 The A-A cutaway diagram, image 3 yes figure 1 The B-B cutaway diagram. The loading lever of the present invention is composed of 2 pieces of channel steel, 3 connecting bolts (including gaskets and nuts), 3 connecting bolt bushings, 2 positioning bolts (including nuts) and 2 positioning bolt bushings. Among them, the channel steel bears the bending load. Three connecting bolts are arranged on the center line of the bottom of the two pieces of channel steel, which are used to connect the channel steel and the connection between the loading lever and other loading levers, and carry the load transferred by the cable connection. The connecting bolt bushing is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com