Phase change heat pump system

A heat pump system and phase change technology, applied in lighting and heating equipment, compressors with reversible circulation, fluid circulation arrangements, etc., can solve problems such as large energy consumption, and achieve the effect of less energy consumption and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

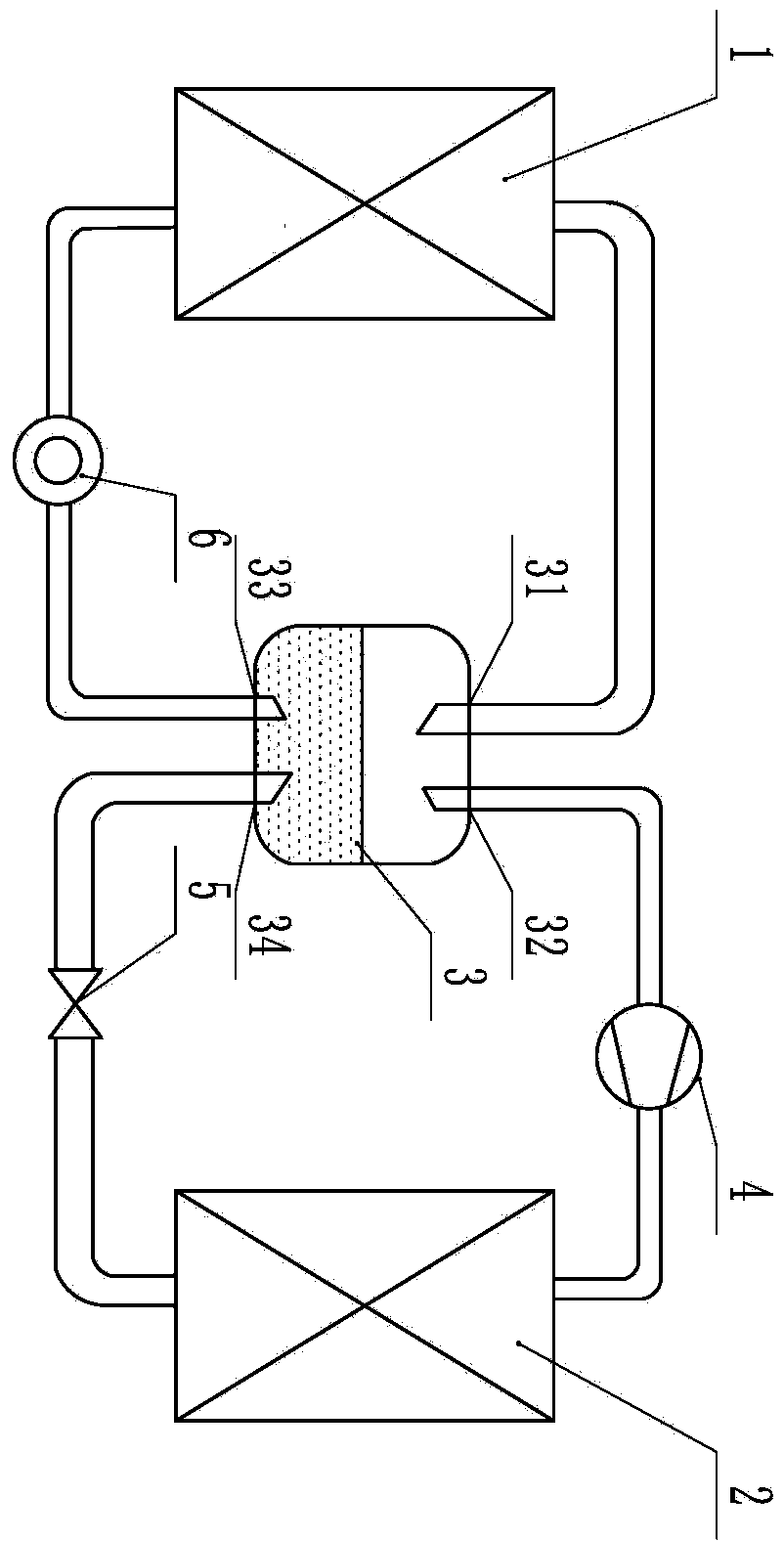

Embodiment 1

[0021] This embodiment is the workflow of the first energy transport, such as figure 1 A working flow chart of a phase change heat pump system is shown, the whole system includes an indoor heat exchanger (1), an outdoor heat exchanger (2), a liquid storage tank (3), a liquid storage tank interface 1 (31), Liquid storage tank port two (32), liquid storage tank port three (33), liquid storage tank port four (34), compressor (4), throttling device (5), circulation pump (6), connection Pipeline and circuit control part; the indoor heat exchanger (1), liquid storage tank (3), circulation pump (6) and connecting pipes form an indoor circulation loop; the outdoor heat exchanger (2), throttling device (5), liquid storage tank (3), compressor (4) and connecting pipes form an outdoor circulation loop; when the phase change heat pump system is working, the circulation pump (6) transfers the liquid working medium from the interface three ( 33) Suction is sent to the indoor heat exchanger...

Embodiment 2

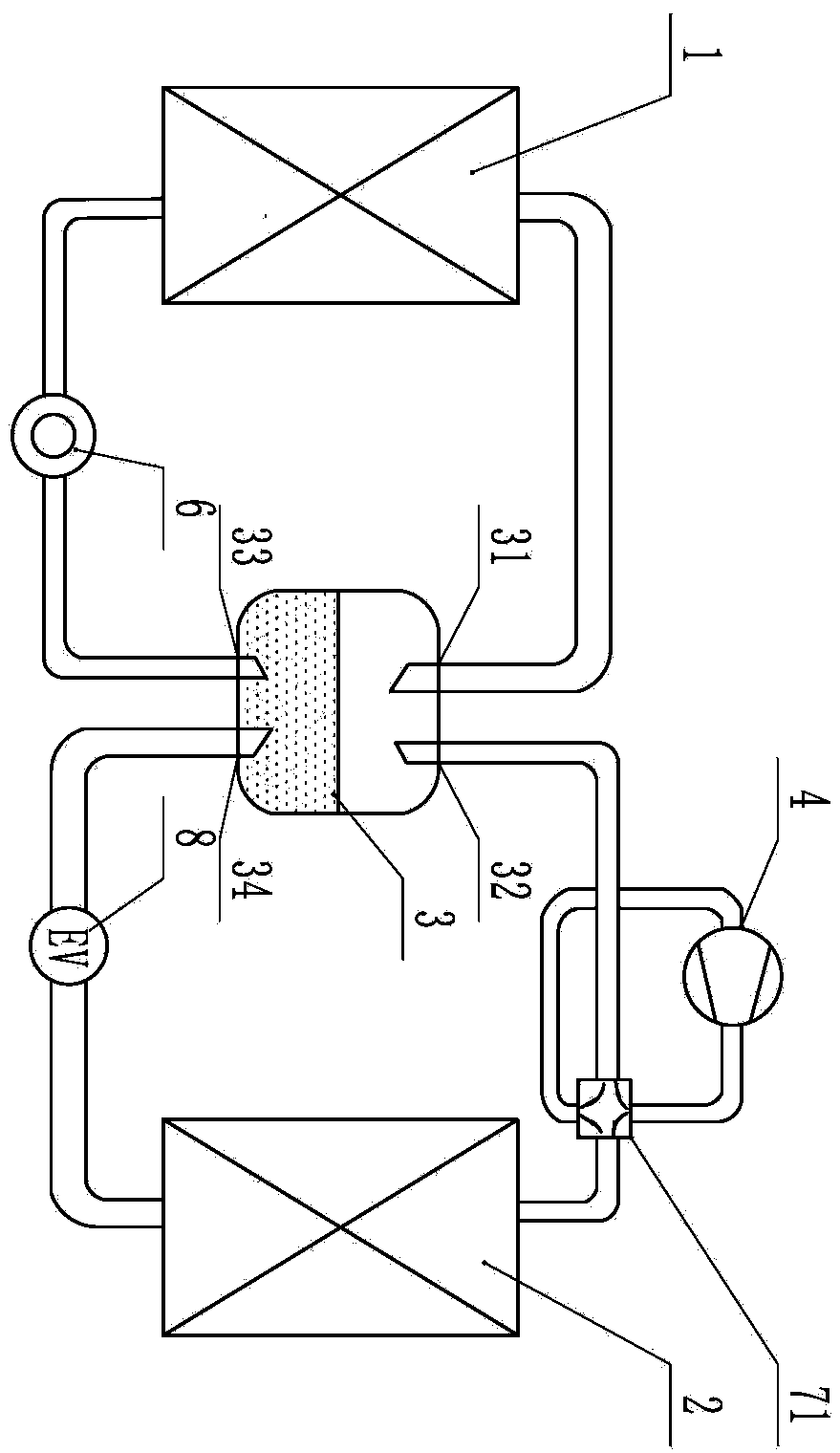

[0023] attached figure 2 It is a schematic diagram of the structure of the second embodiment of the present invention, so that the functions of the indoor heat exchanger (1) and the outdoor heat exchanger (2) in the system are exchanged, that is, the outdoor heat exchanger (2) acts as an evaporator function, the indoor heat exchanger (1) plays the role of a condenser, which is improved on the basis of the first embodiment.

[0024] The circulation pump (6) is replaced by a two-way power motor system (such as a Roots motor) that can directly change the direction from a one-way circulation pump. The compressor (4) is connected in series with a four-way valve one (71); the throttling device (5) is Electronic expansion valve (8); the other components are the same as those in the first embodiment, and its start-up and operation process are the same as those in the first embodiment.

[0025] When the phase-change heat pump system is cooling, the specific working mode is the same a...

Embodiment 3

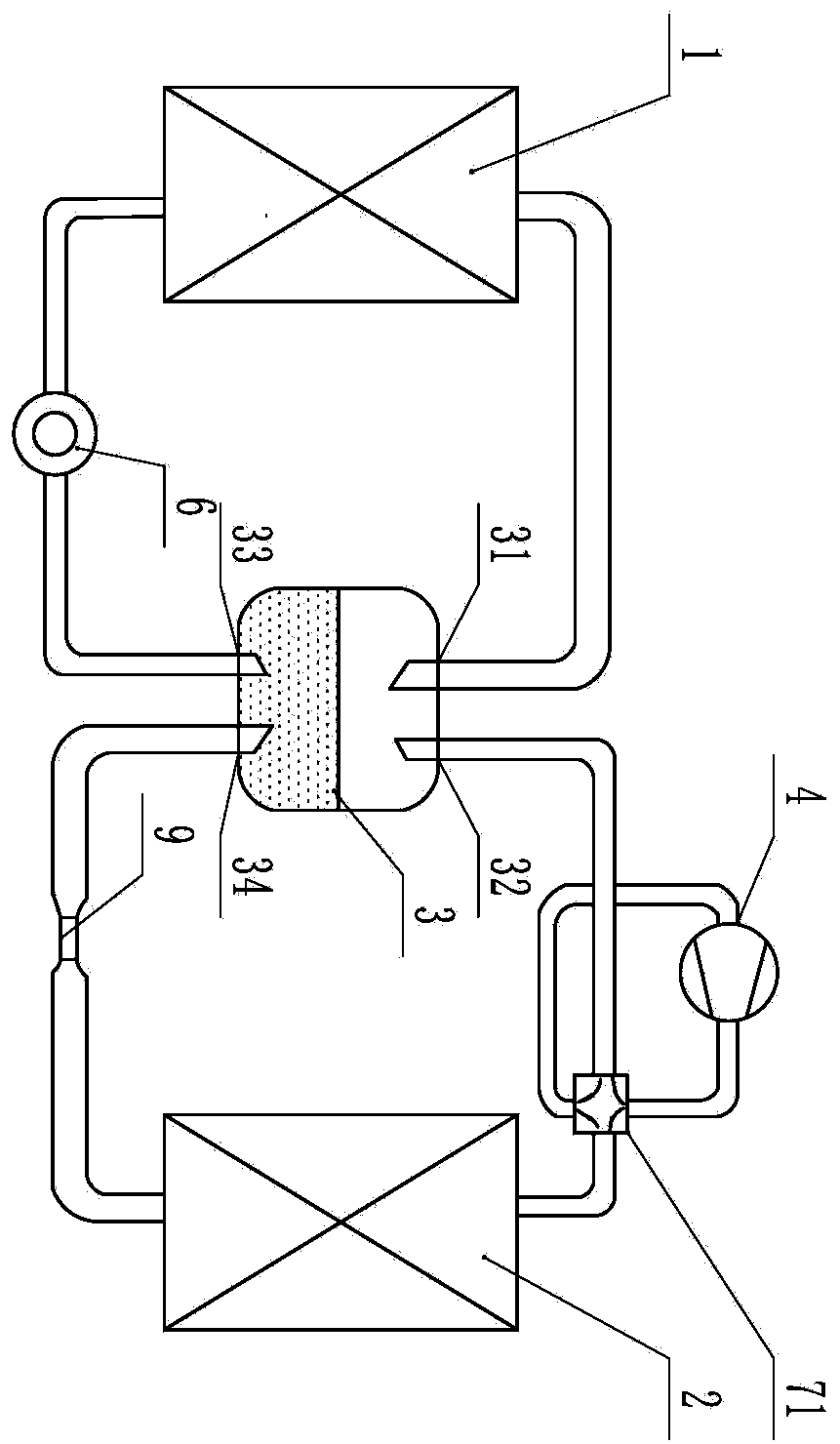

[0028] attached image 3 It is a structural schematic diagram of the third embodiment of the present invention, except that the electronic expansion valve (8) is replaced by a capillary (9), other components are the same as in the second embodiment, and its start-up and operation process are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com