Guide mechanism of drainage valve shell

A technology of drainage valve and guide structure, which is applied in the field of bathroom, can solve the problems affecting the guide performance of guide tubes, and achieve the effect of high product guide precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

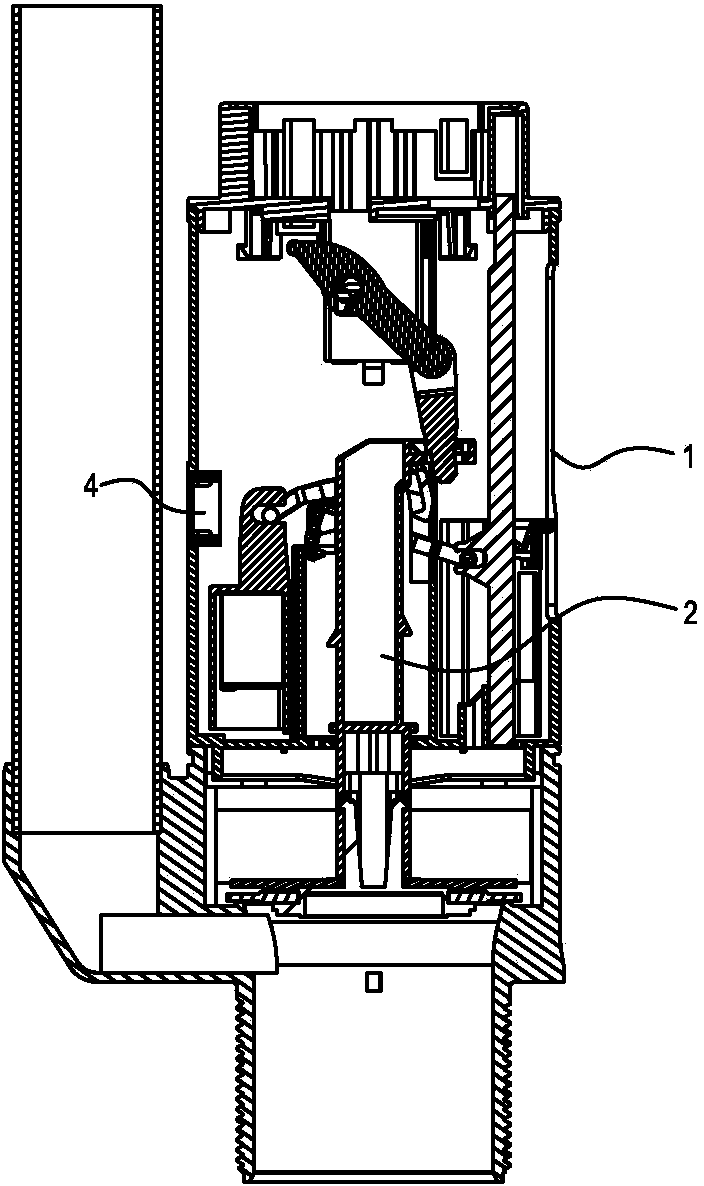

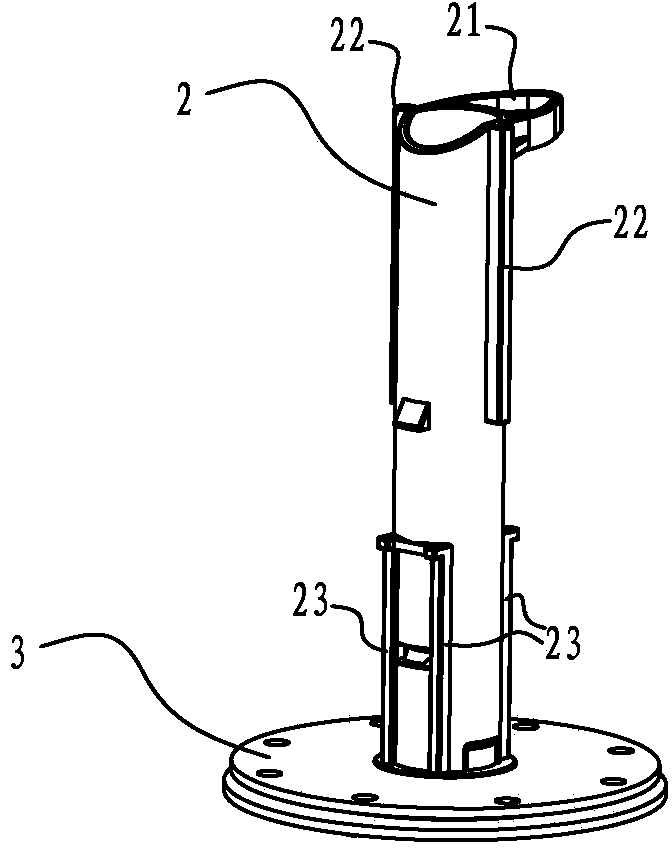

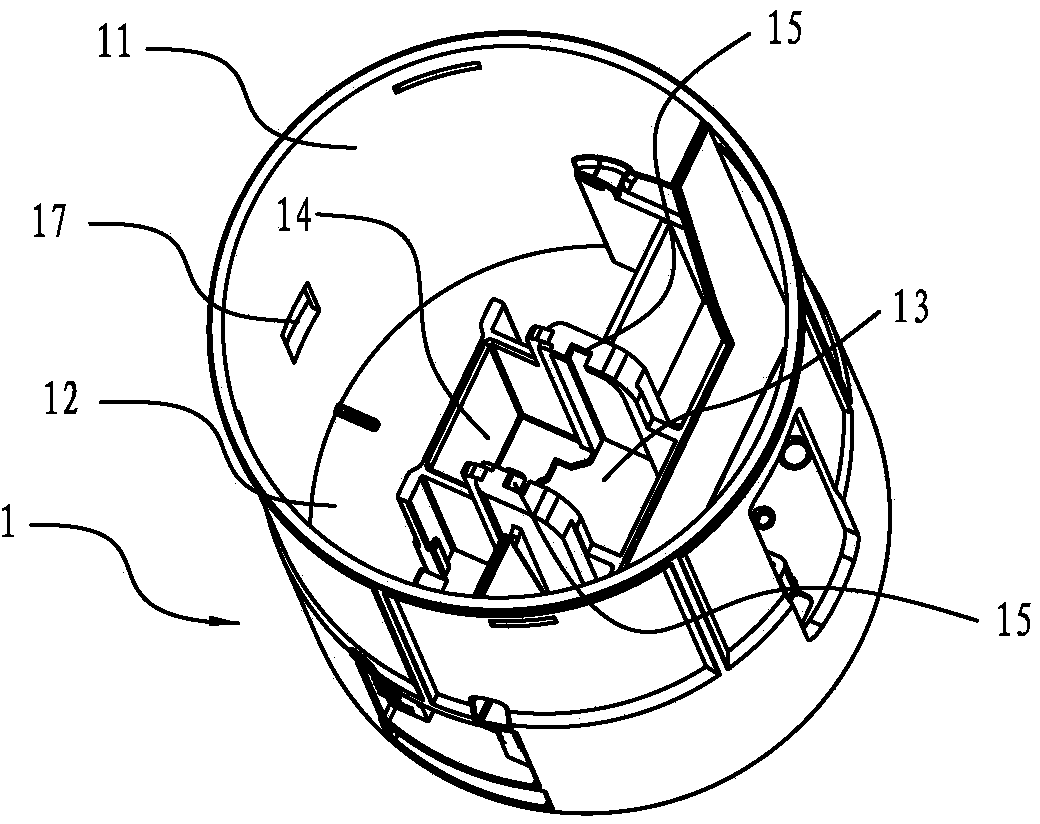

[0032] For specific embodiments of the present invention, refer to Figure 1 to Figure 4 A casing 1 of a drain valve is a cylindrical shape with one end closed, and it includes a cylindrical wall 11 and a bottom plate 12 at the lower end.

[0033] A central guide hole 13 is provided at the center of the bottom plate 11 . Around the central guide hole 13, a square surrounding wall 14 is provided upwards, and the bottom plate 12 and the surrounding wall 14 are integrally formed. The bottom plate and the cylinder wall are independent parts respectively. Wherein, the two sides of central guide hole 13, the inner upper end of surrounding wall 14 are symmetrically provided with a pair of guide grooves 15 in the vertical direction, wherein, the guide position of central guide hole 13 is 13-1 (that is, cooperates with the guide rib 23 of the conduit. position), the guide groove 15 and the guide position 13-1 do not coincide on the vertical projection.

[0034] A through hole 17 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com