A kind of AC motor rotor manufacturing assembly assembly machine and assembly method

A technology for AC motors and rotors, which is applied in the manufacture of stator/rotor bodies, etc., which can solve problems such as inability to adjust, misalignment of rotor and stator assembly, and inability to clamp and limit the rotor, so as to reduce assembly time, avoid assembly misalignment, and increase The effect of the occasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

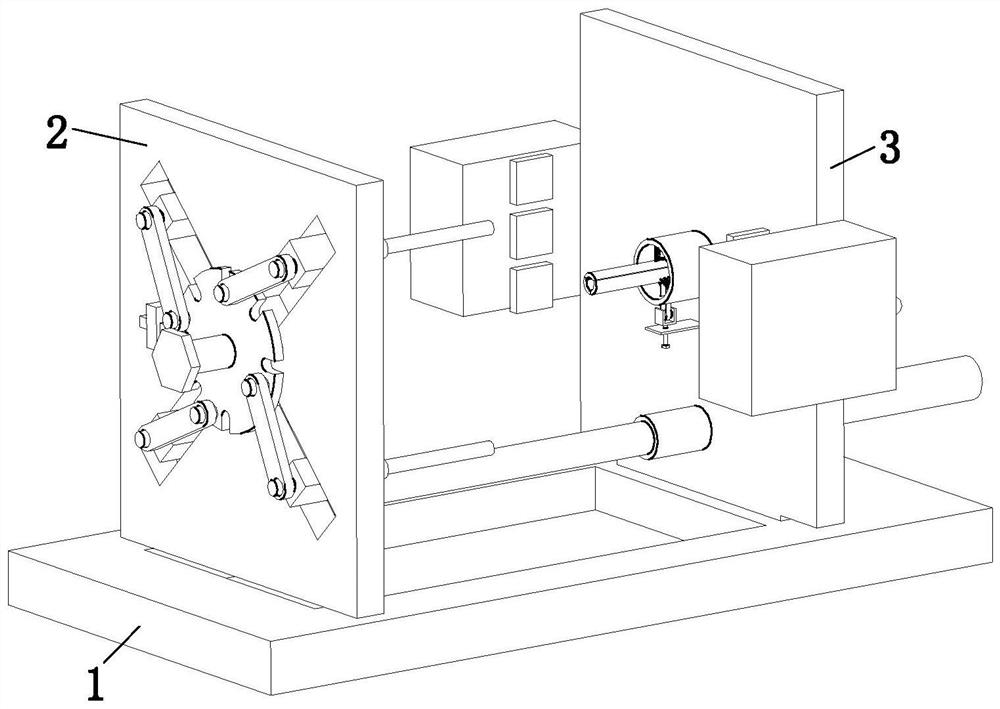

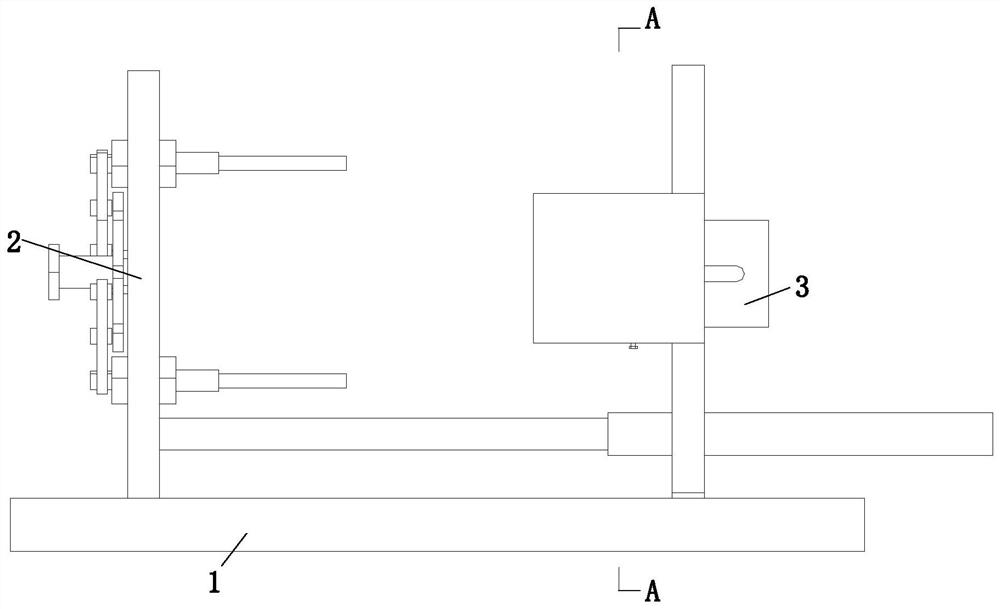

[0034] Such as Figure 1 to Figure 8 As shown, an AC motor rotor manufacturing, assembling and assembling machine includes a placement board 1, a support device 2 and a plug-in device 3, the upper end of the placement board 1 is connected to the support device 2 through a sliding fit, and the upper end of the placement board 1 is far away from The supporting device 2 is provided with a plug-in device 3 , and the plug-in device 3 is installed on the placement board 1 .

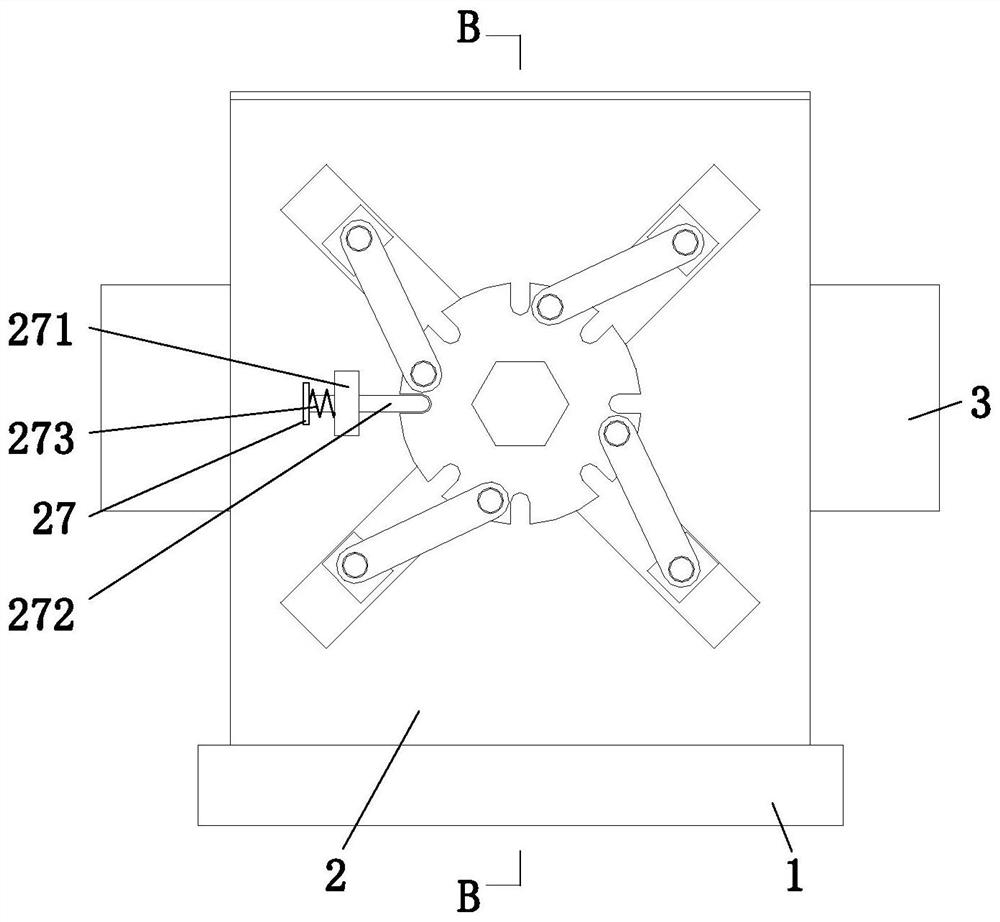

[0035] The supporting device 2 includes a sliding plate 21, a rotating plate 22, a rotating handle 23, a transmission rod 24, a sliding block 25, a placing mechanism 26 and a limit mechanism 27, and the upper end of the placing plate 1 is connected by a sliding fit. Sliding plate 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com