Connector and manufacturing method thereof

A connector, front and rear direction technology, applied in the field of connectors and their manufacturing, can solve the problems of inconvenient assembly of an insulating body, a small lens, etc., achieve convenient and rapid assembly, and avoid assembly dislocation problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

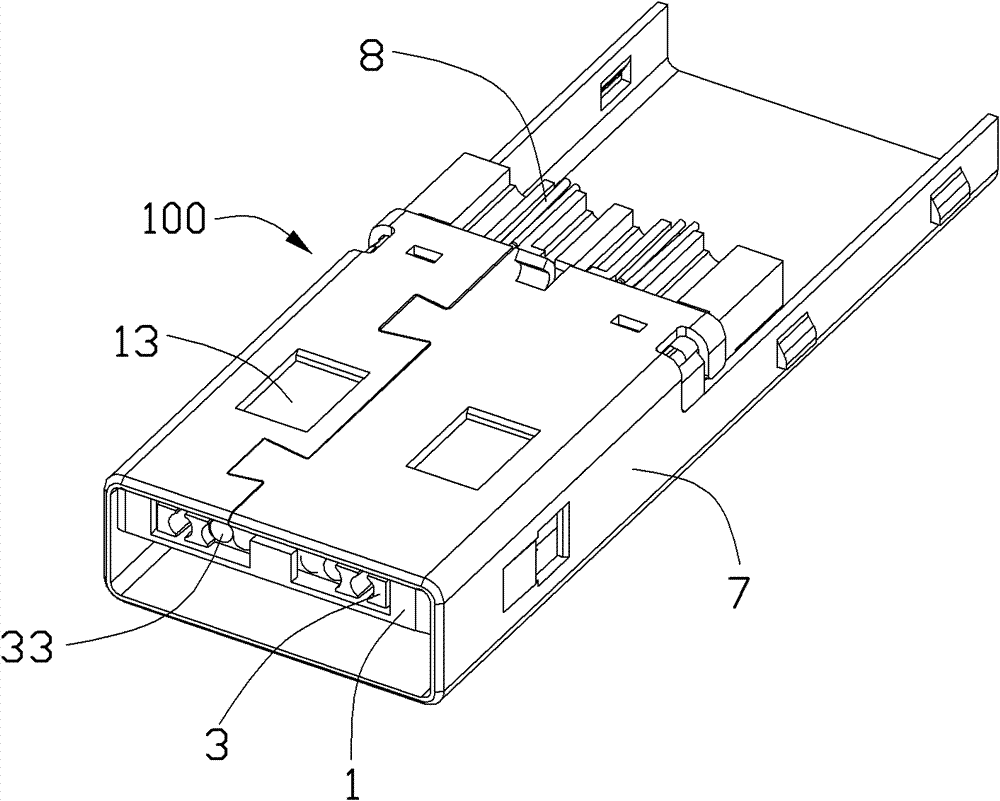

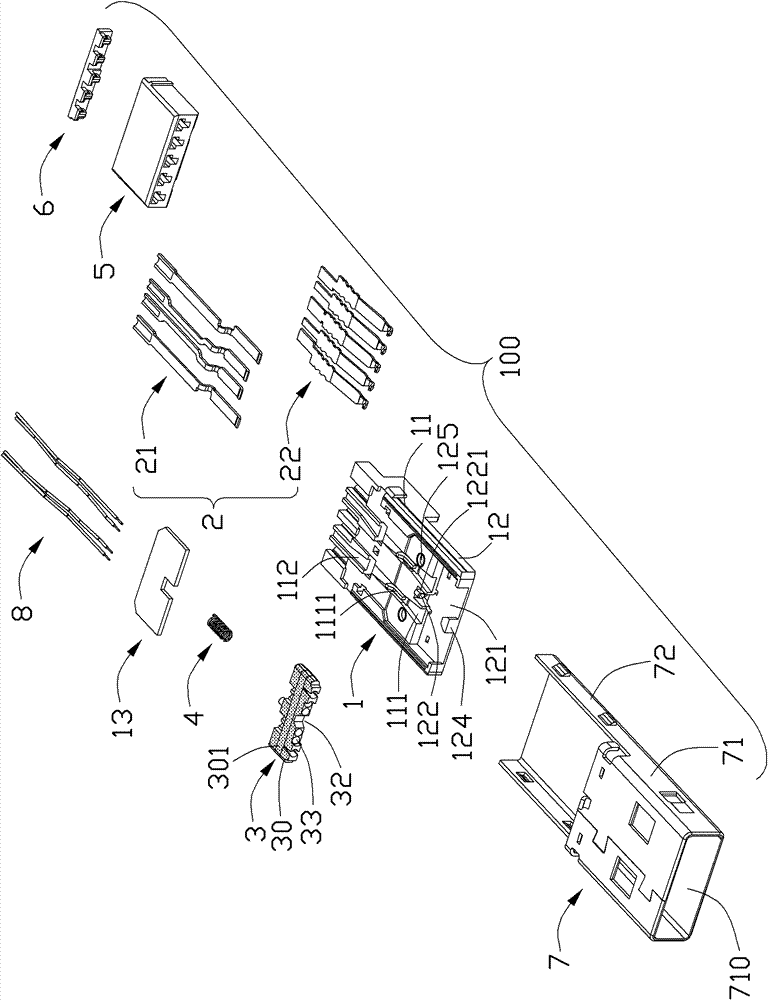

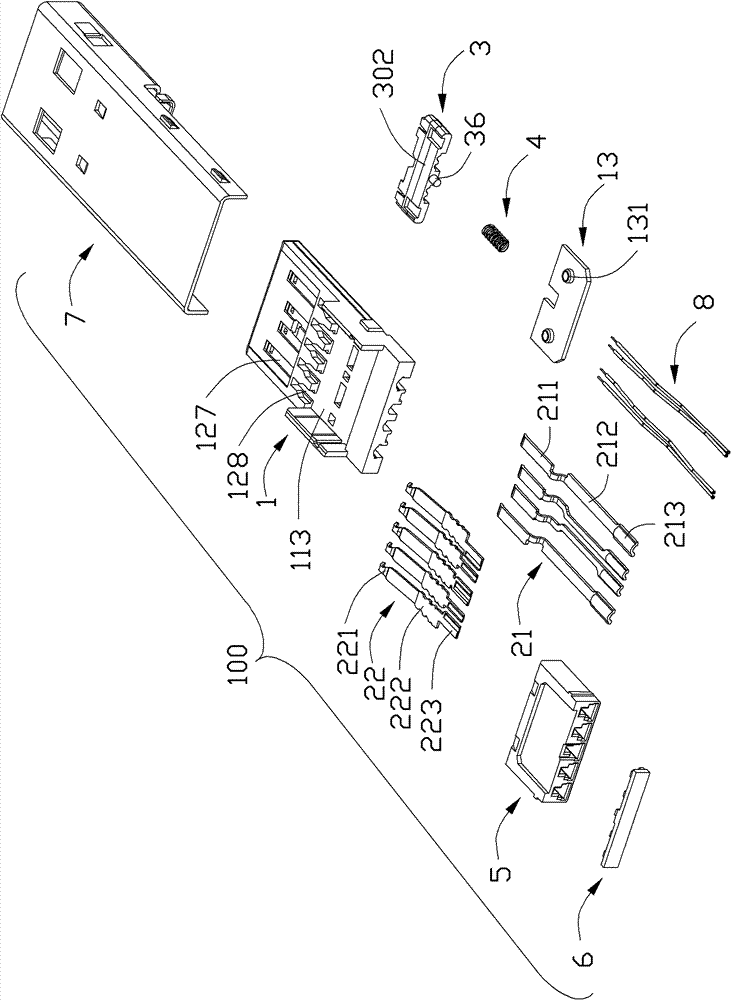

[0012] see Figure 1 to Figure 4 The connector 100 of the present invention includes an insulating body 1, a number of conductive terminals 2 held on the insulating body 1, an optical module 3 mounted on the insulating body 1, and an elastic member 4 clamped between the insulating body 1 and the optical module 3 (a spring in this embodiment), a seat body 5 held on the insulating body 1 , a positioning block 6 matched with the seat body 5 , and an optical fiber 8 connected to the optical module 3 .

[0013] The insulating housing 1 includes a main body 11 and a tongue 12 extending forward from a front end of the main body 11 .

[0014] A pair of grooves 111 separated from each other are provided at the front part above the main body part 11 of the insulating body 1 and at the rear part above the tongue plate 12. The front part of the groove 111 is wider than its rear part and middle part, so that the groove 111 Tapering forward and backward. A long and thin rib 1111 is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com