Anti-dislocation whole-vehicle assembling equipment for electric power-assisted tricycle

A technology for electric power assist and assembly equipment, which is applied in the direction of electric vehicles, assembly machines, metal processing equipment, etc. It can solve the problems of insufficiently stable installation, unfixed clamping position, and lack of anti-displacement components, etc., to improve assembly accuracy and avoid The effect of dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

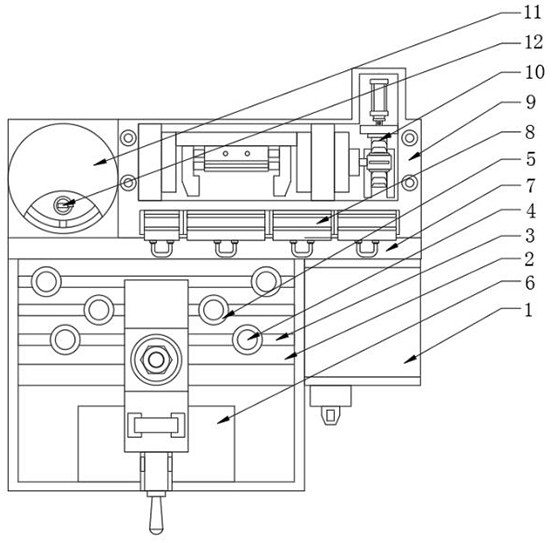

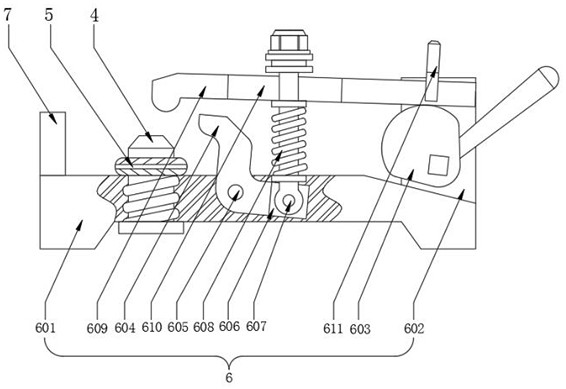

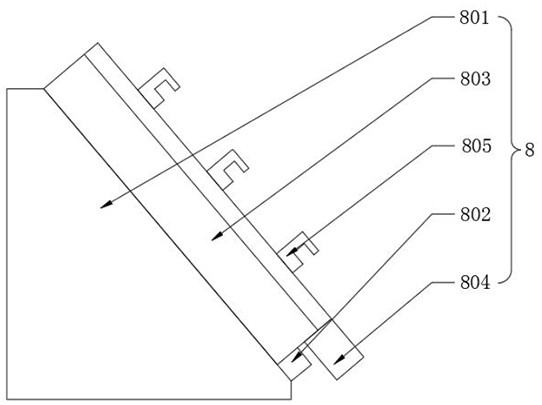

[0022] see Figure 1-Figure 8 , the present invention provides a technical solution: comprising a conveyor belt 1 and an anti-displacement mechanism 6, a worktable 2 is provided at the end of the conveyor belt 1, and a chute 3 is opened on the surface of the worktable 2, and a support rod 4 is slidably installed inside the chute 3, and The top of the support rod 4 is engaged with a rotating handle 5, and the lower end surface of the worktable 2 is equipped with an anti-displacement mechanism 6, and the anti-displacement mechanism 6 includes a base 601, a boss 602, an eccentric 603, a side pressure piece 604, a bearing 605 and an elbow Section 606, a boss 602 is fixedly installed on the right end face of the base 601, and an eccentric wheel 603 is rotatably installed inside the boss 602, a side pressure piece 604 is rotatably installed in the middle of the base 601, and a bearing 605 is installed in the middle of the side pressure piece 604. , the side pressing member 604 is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com