A device for dry removal of cathode plate ammonium sulfate crystals and recycling

A cathode plate, ammonium sulfate technology, applied in the improvement of process efficiency, photography process, instruments, etc., can solve the problems of environmental water pollution, large amount of cleaning wastewater, waste of ammonium sulfate resources, etc., to reduce pollution, improve work efficiency, The effect of reducing personnel costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

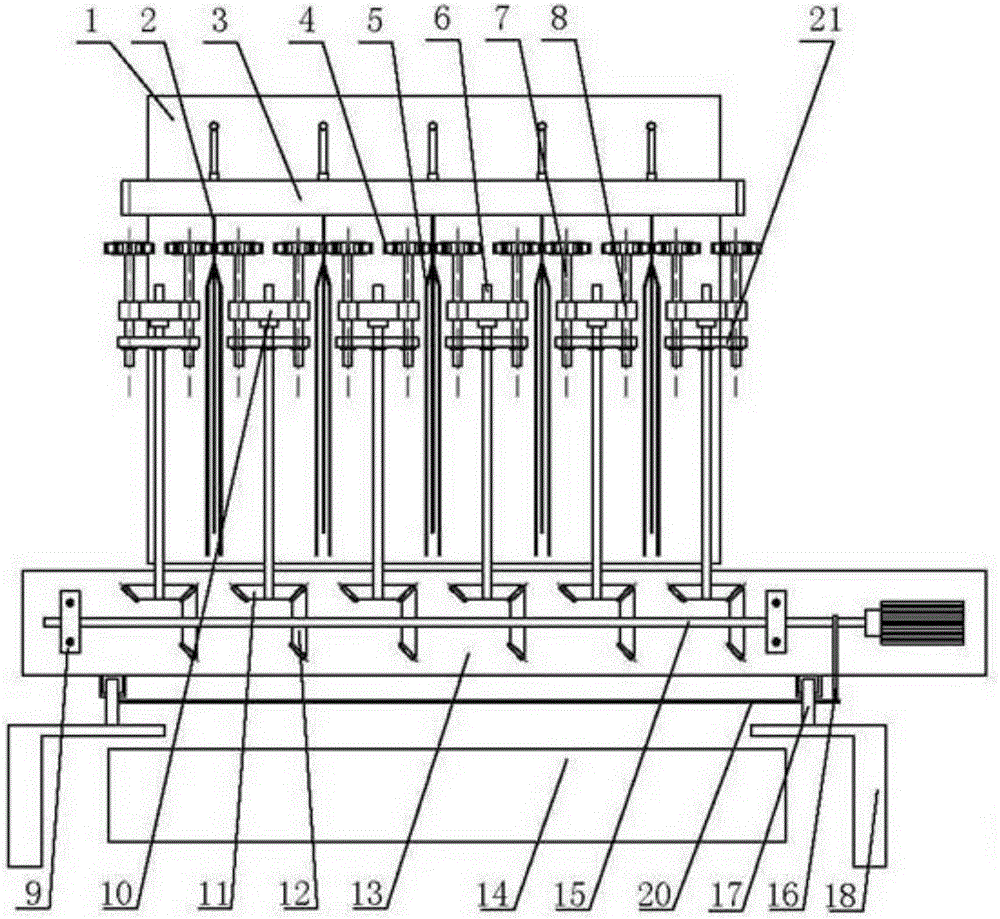

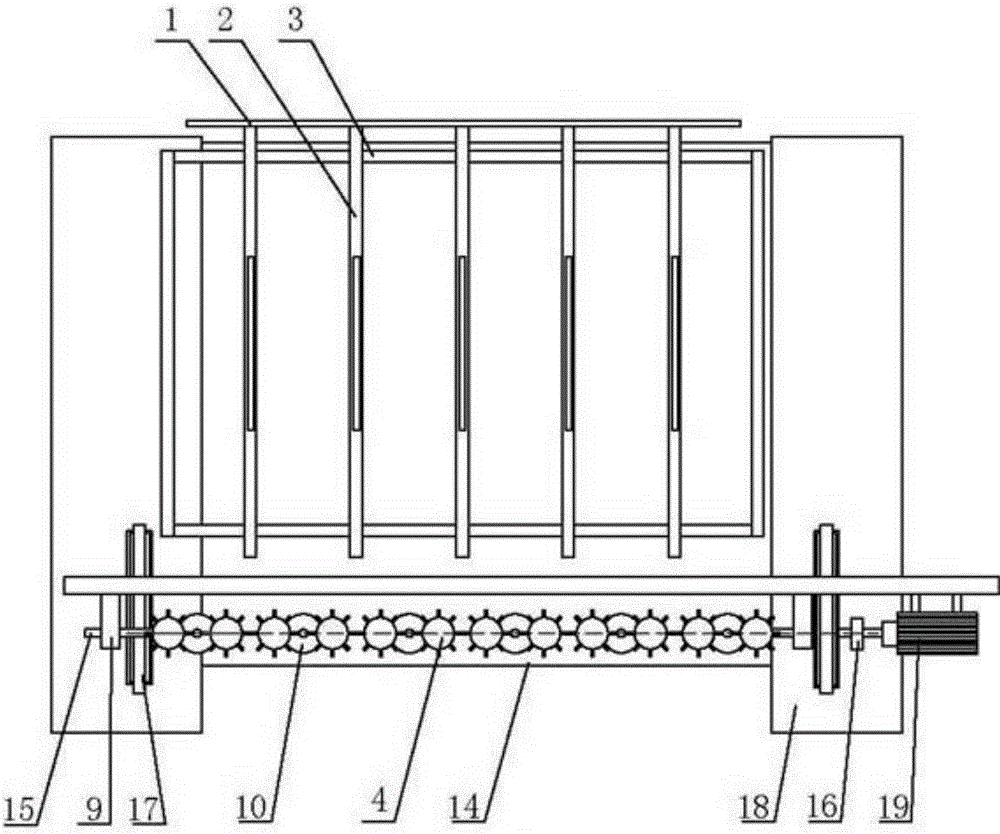

[0026] Such as figure 1 with figure 2 Shown, a kind of dry method removes the device of cathode plate ammonium sulfate crystallization and recycling, comprises baffle plate 1, cathode plate 2, cathode plate beam 3, ammonium sulfate collection box 14, rolling shovel 4, drive motor 19, driving part and In the walking part, the cathode plate 2 is suspended on the cathode plate beam 3, and an ammonium sulfate collection box 14 is provided below the cathode plate 2, and a baffle plate 1 is provided on one side of the cathode plate 2, and a baffle plate 1 is provided on the other side. There are scoops 4, drive motors 19, driving parts and walking parts, there are at least two scoops 4, the gap between the scoops 4 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com