Zinc oxide pre-dispersed masterbatch particle and preparation method and applications thereof

A technology of pre-dispersed masterbatch and zinc oxide, applied in the field of rubber additives, can solve the problems of slow mixing speed and dispersion speed, long rubber vulcanization time, uneven dispersion, etc. The effect of adding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

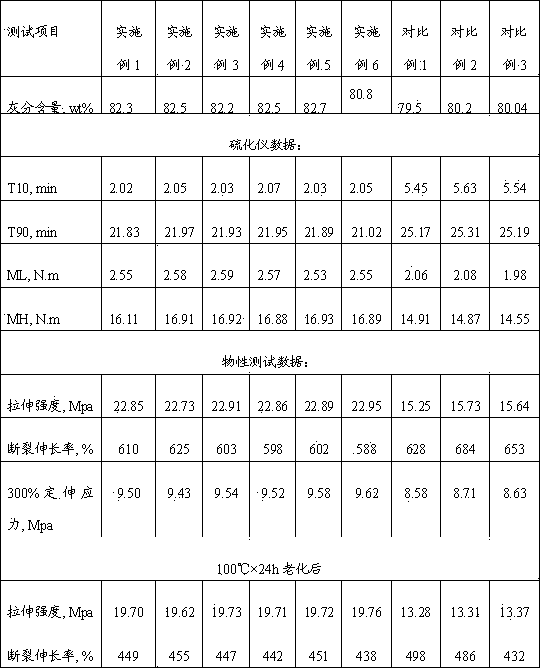

Examples

Embodiment 1

[0026] The zinc oxide pre-dispersed masterbatch described in this embodiment is composed of the following components by mass: 80 parts of zinc oxide powder; 4 parts of EPDM; 5 parts of BR; 4 parts of fatty acid zinc; 4 parts of zinc oleate; 3 parts of isobutylene sulfide share.

[0027] The preparation method of the zinc oxide pre-dispersed masterbatch particles described in the present embodiment is as follows:

[0028] (1) Put 4 parts of EPDM and 5 parts of butadiene rubber BR into the open mill, and mix evenly at room temperature to obtain the required rubber carrier;

[0029] (2) Add 80 parts of zinc oxide powder, the rubber carrier, 4 parts of fatty acid zinc, 4 parts of oleic acid zinc and 3 parts of vulcanized isobutylene into the internal mixer, and mix at 40°C. The feeding form enters the granulation equipment for granulation, and the short columnar zinc oxide masterbatch particles are obtained through extrusion granulation.

Embodiment 2

[0031] The zinc oxide pre-dispersed masterbatch described in this embodiment is composed of the following components by mass: 80 parts of zinc oxide powder; 5 parts of EPDM; 4 parts of BR; 6 parts of fatty acid zinc; 2 parts of zinc oleate; 3 parts of isobutylene sulfide share.

[0032] The preparation method of the zinc oxide pre-dispersed masterbatch particles described in the present embodiment is as follows:

[0033] (1) Put EPDM and butadiene rubber BR into the open mixer, and mix them uniformly at room temperature to obtain the required rubber carrier;

[0034] (2) Add zinc oxide powder, the rubber carrier, fatty acid zinc, oleic acid zinc and isobutylene vulcanization into the internal mixer, mix at 50°C, and enter the granulation equipment in the form of cold feed after mixing. Granules, after extrusion granulation to obtain short columnar zinc oxide masterbatch particles.

Embodiment 3

[0036] The zinc oxide pre-dispersed masterbatch described in this embodiment is composed of the following components by mass: 80 parts of zinc oxide powder; 6 parts of EPDM; 3 parts of BR; 2 parts of fatty acid zinc; 6 parts of zinc oleate; 3 parts of isobutylene sulfide share.

[0037] The preparation method of the zinc oxide pre-dispersed masterbatch particles described in the present embodiment is as follows:

[0038] (1) Put EPDM and butadiene rubber BR into the open mixer, and mix them uniformly at room temperature to obtain the required rubber carrier;

[0039] (2) Add zinc oxide powder, the rubber carrier, fatty acid zinc, oleic acid zinc and isobutylene vulcanization into the internal mixer, mix at 60°C, and enter the granulation equipment in the form of cold feed after mixing. Granules, after extrusion granulation to obtain short columnar zinc oxide masterbatch particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com