Roller device

A technology of equipment and guide rollers, applied in the direction of roller table, roller column, semiconductor/solid-state device manufacturing, etc., can solve problems such as damage to transfer objects and reduction of product production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

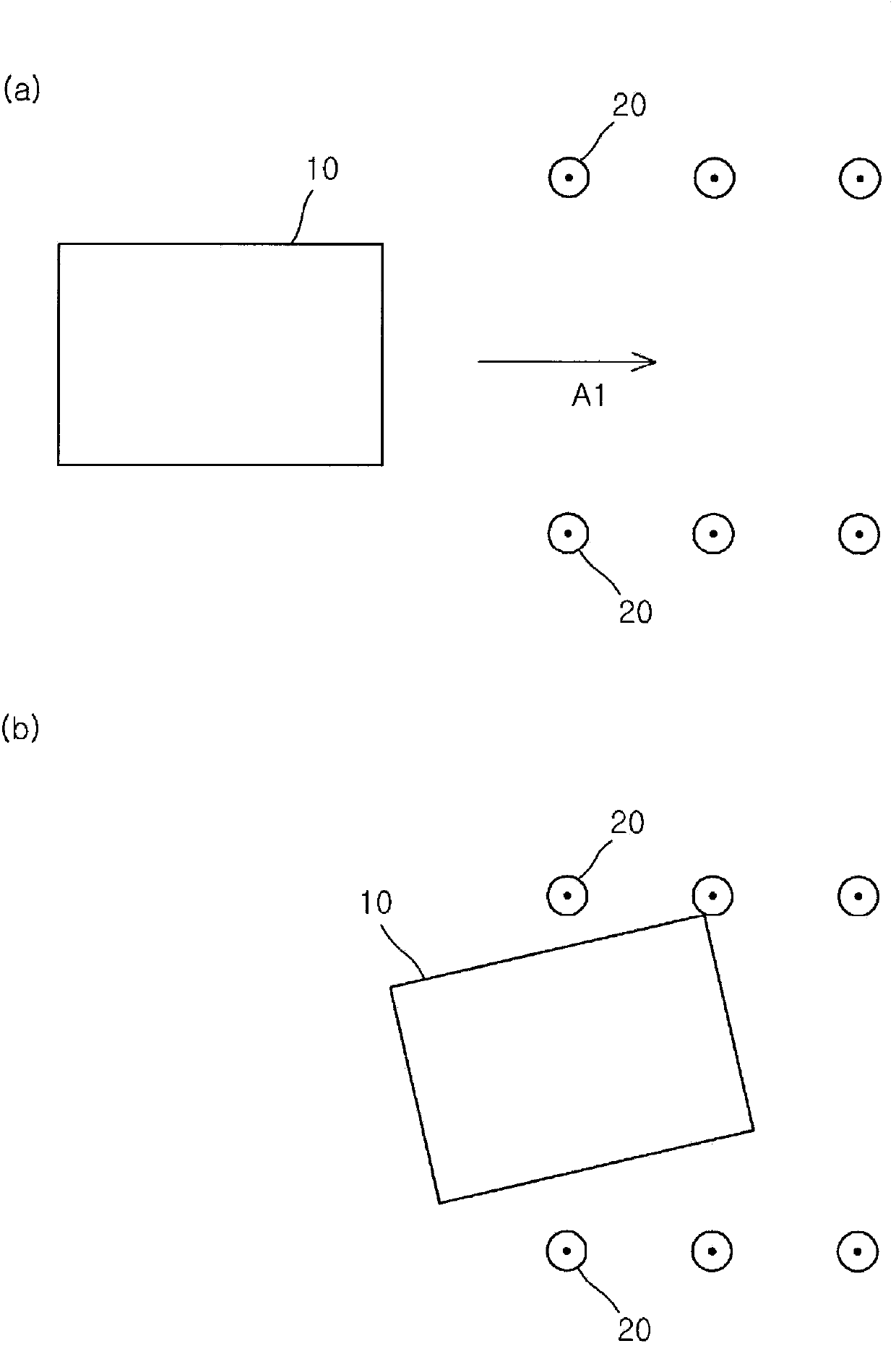

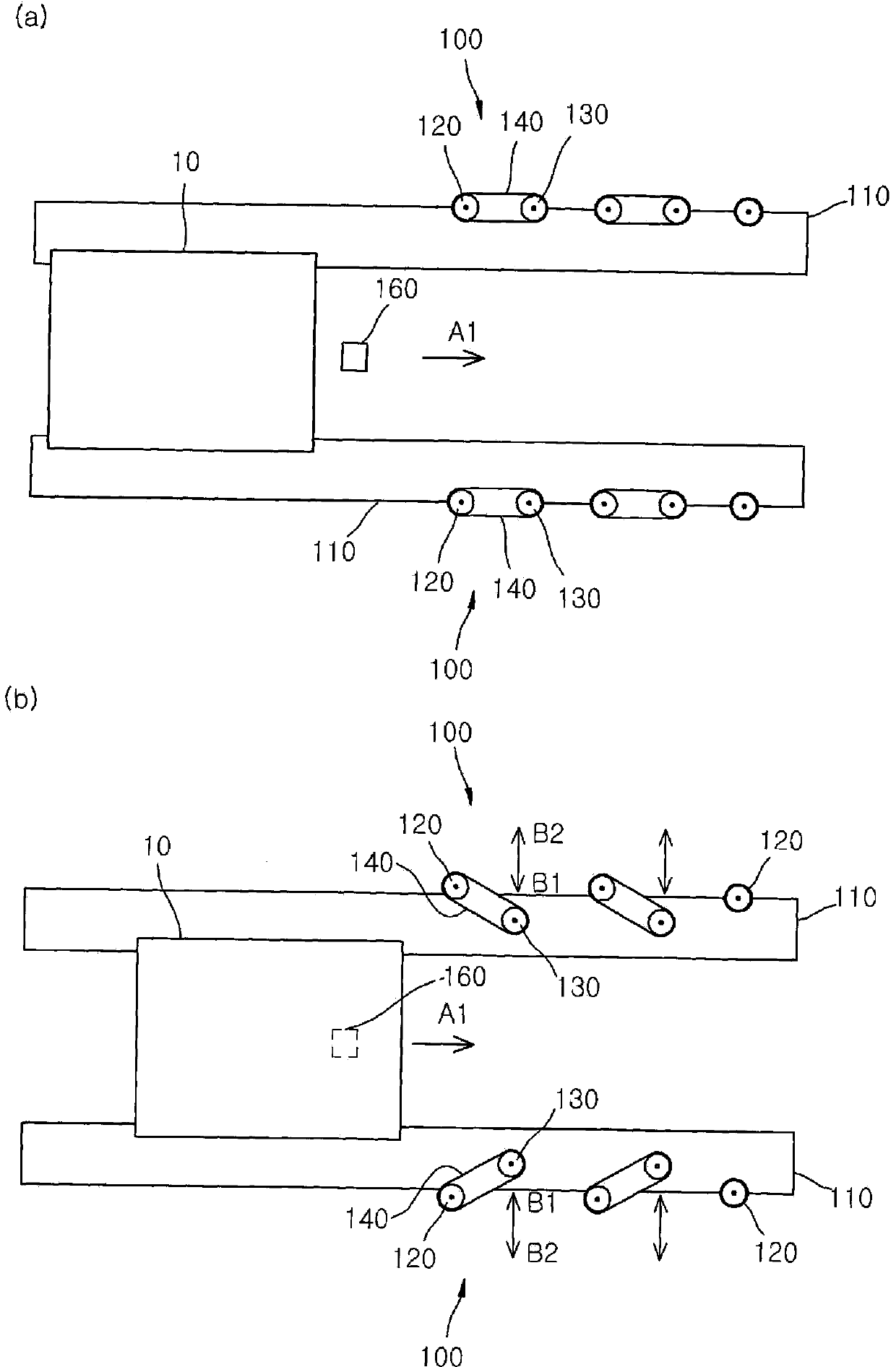

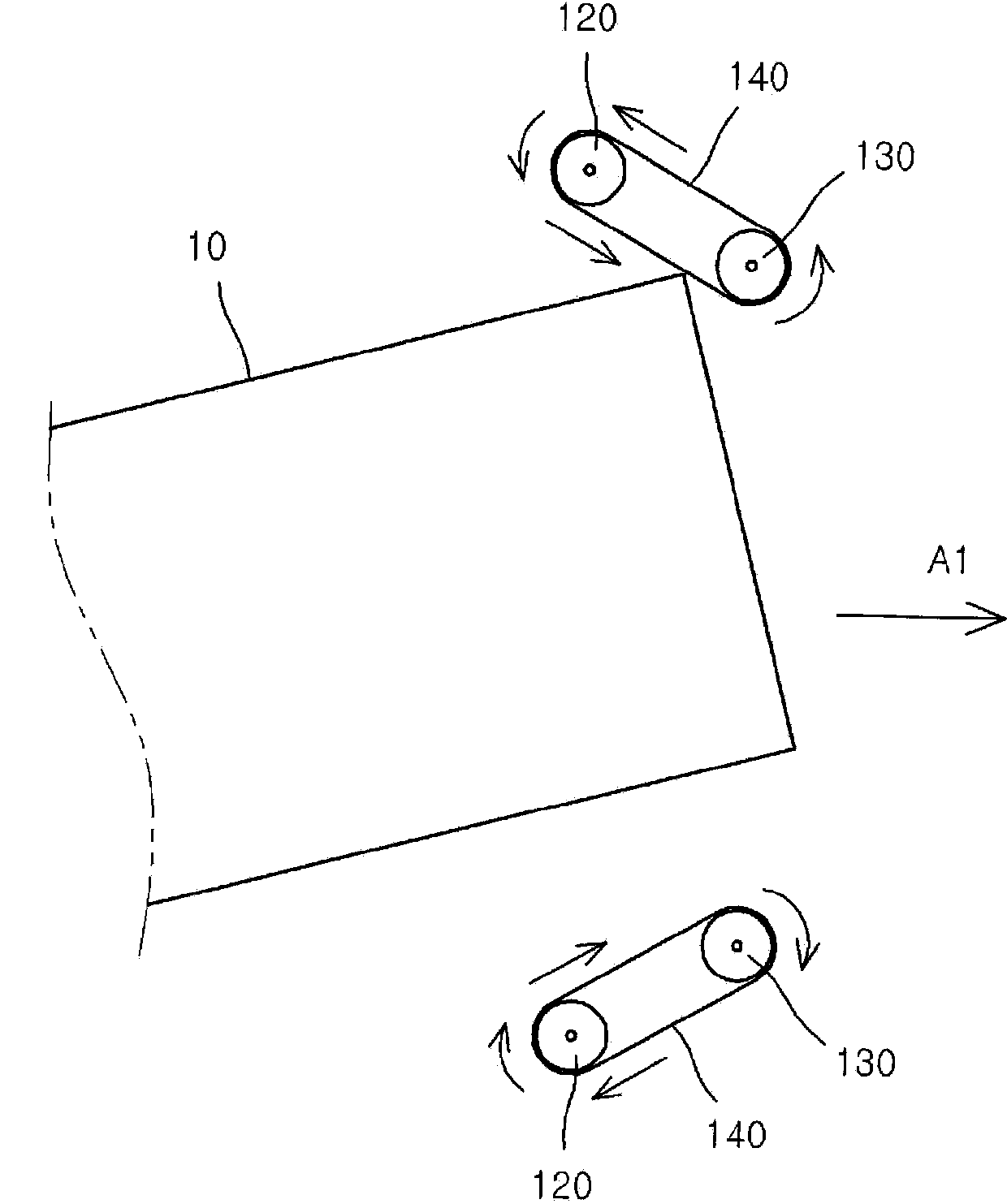

[0019] Hereinafter, an embodiment of a guide roller apparatus according to the present invention will be described with reference to the accompanying drawings.

[0020] figure 2 is a view showing a guide roller device according to an embodiment of the present invention; image 3 to show the figure 2 The view of the first roller, the second roller and the belt rotated by the first roller rotary drive of the guide roller device; Figure 4 To illustrate when the passed object is not passed along the passed direction figure 2 a view of the operation of the second roll of the guide roll apparatus; and Figure 5 for showing figure 2 View of the spring member of the guide roller device.

[0021] refer to Figure 2 to Figure 5 , the guide roller device 100 in this embodiment includes a transfer unit 110, a plurality of first rollers 120, a second roller 130, a belt 140, a second roller moving unit (not shown), a first roller rotation driver (not shown Out), a controller (no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com