Bare bobbin conveying device of automatic winder

An automatic winding and conveying device technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of lifting belt block jamming, easy jamming of empty bobbins, and shortened service life. Easy to install and operate, avoid being stuck, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings:

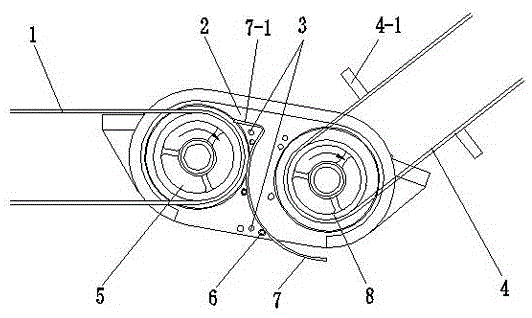

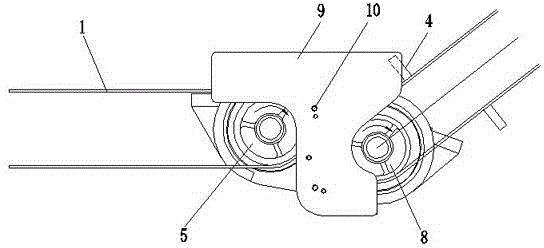

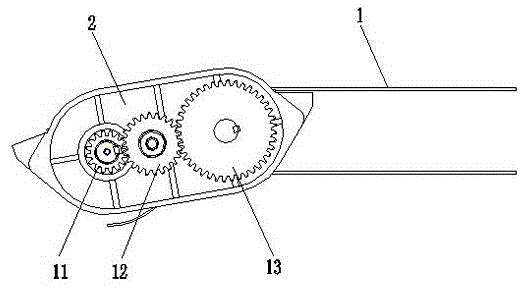

[0021] see Figure 1-Figure 2 , An embodiment of an empty pipe conveying device of the present invention includes: a gearbox 2, a flat belt 1, a flat pulley 5, a lifting pulley 8, a lifting belt 4, and a block 4-1 on the lifting belt 4.

[0022] Increase the minimum distance between the existing flat pulley 5 and the lifting pulley 8, and make the height of the stopper 4-1 be promoted. An arc guard plate 7 is set between the flat pulley 5 and the lifting pulley 8, the concave surface of the arc guard plate 7 faces the lifting pulley 8, and the radian of the arc guard plate 7 is consistent with the lifting pulley 8 , the distance between the two remains uniform. The lower end of the arc guard plate 7 is located below the hoisting pulley 8, and the upper end of the arc guard plate 7 is close to the flat belt 1 upper layer on the flat pulley 5.

[0023] The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com