A kind of blanket reducing agent for printing

A reducing agent and blanket technology, applied in the field of cleaning agents, can solve the problems of lack of improving the printing suitability of the blanket, unable to restore the elasticity of the blanket, and restoring the elasticity, so as to eliminate the phenomenon of surface hardening, not damage human health, and prolong the use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

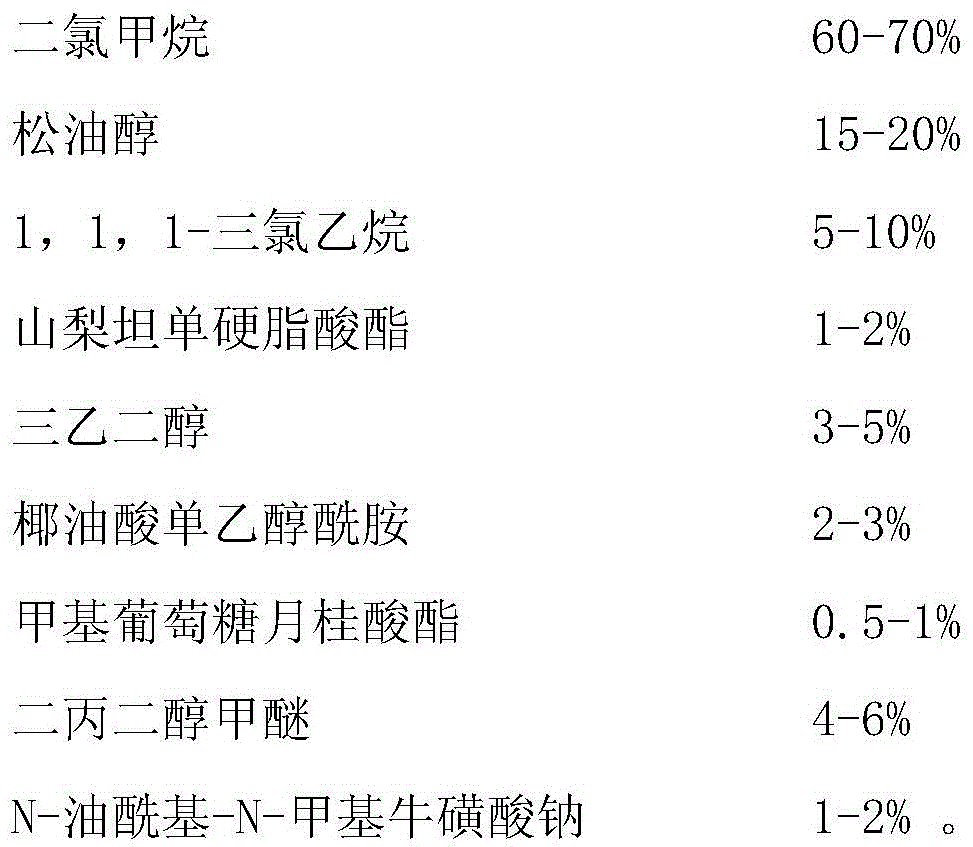

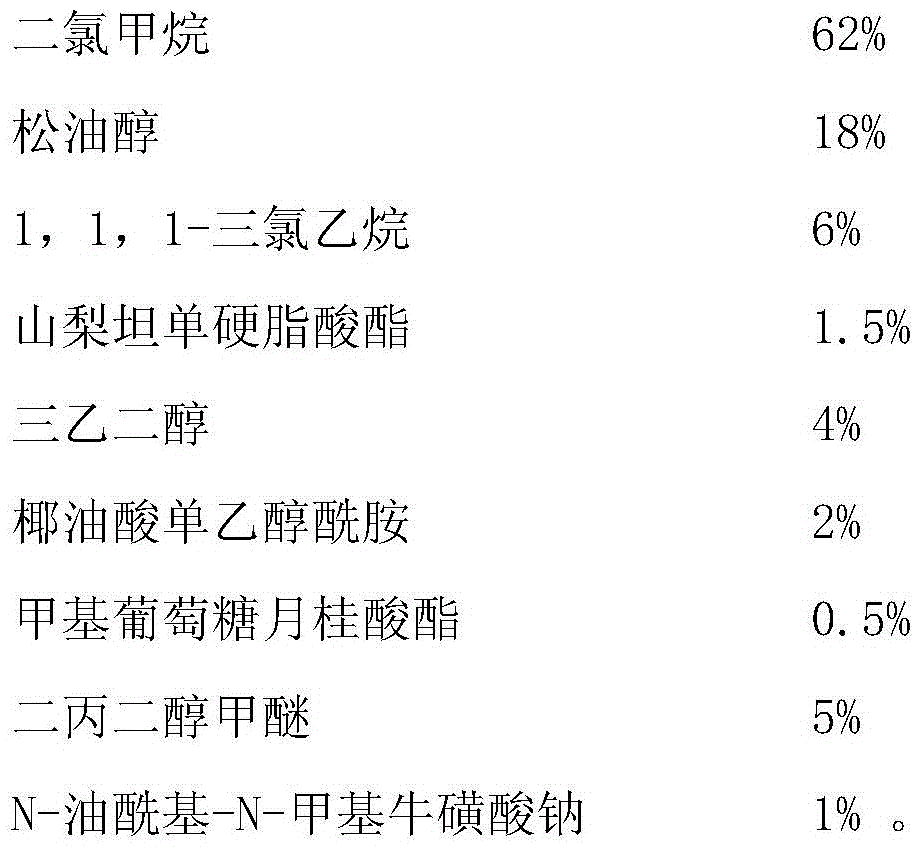

[0013] A blanket reducing agent for printing is made up of the following raw materials in parts by weight:

[0014]

[0015] Stir the above-mentioned raw materials evenly at room temperature according to the formula ratio, and use a cloth ball or yarn ball to dye an appropriate amount of the reducing agent of the present invention on the surface of the blanket and rub it evenly, and the depression can be restored to level within 1 minute. It can be dissolved and emulsified by left and right, and can be completely decontaminated by scrubbing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com