Circulating water cooling device in film tube of film blowing machine

A technology for a water cooling device and a film blowing machine, which is applied to the field of circulating water cooling devices in a film tube of a film blowing machine, can solve the problems of poor cooling effect, waste of water resources, etc., and achieve the effects of energy saving and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

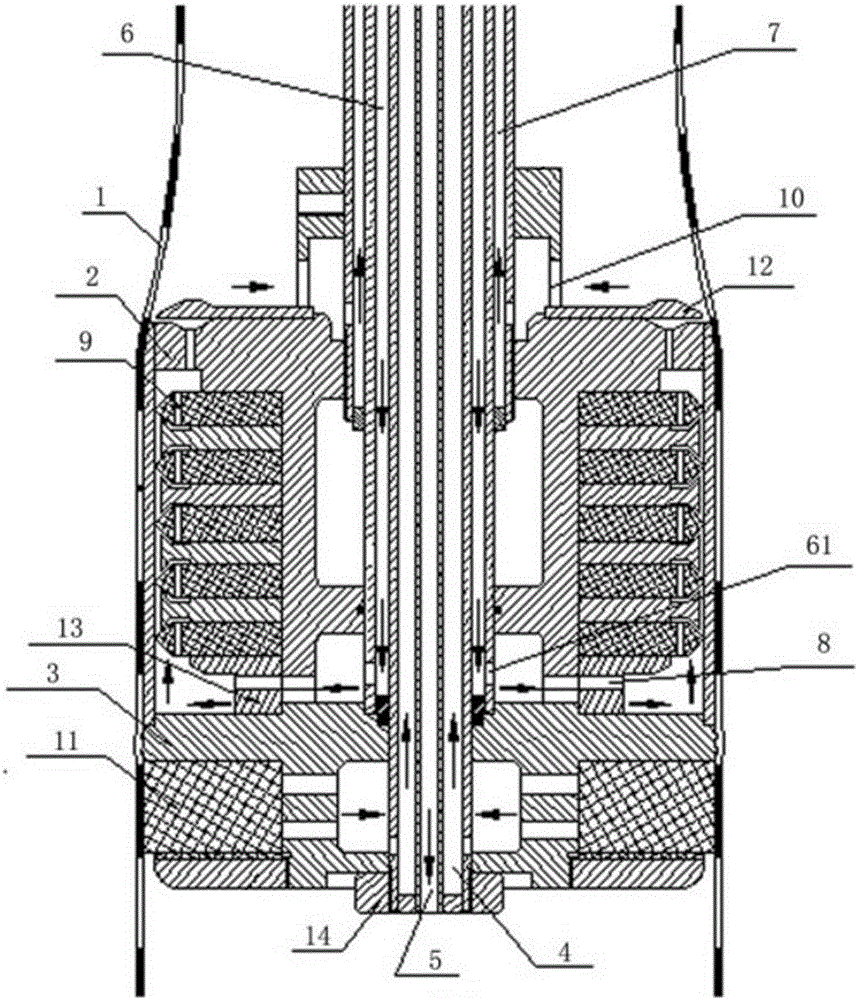

[0017] refer to figure 1 , figure 2 , a circulating water cooling device in the film tube of a film blowing machine, in which a cooling mandrel 2 is arranged in the film tube 1, and the cooling mandrel 2 of the present invention adopts metal aluminum as the mold core, because metal aluminum is relatively light in weight, The heat transfer speed is fast, and the price is relatively cheap; the cooling mandrel 2 is provided with a vacuum chamber 3, and the center of the vacuum chamber 3 is provided with an air inlet pipe 4, because the function of the vacuum chamber 3 is through the water-absorbing ring 11 Carry out vacuum suction to the water film attached to the membrane tube 1, in order to prevent the membrane tube 1 after cooling from being deformed by vacuum suction, the air inlet pipe 4 is provided in the present invention to keep the membrane The shape of the pipe 1 is to facilitate the smooth progress of the next process; the periphery of the air inlet pipe 4 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com