Cooling system and method for electronic components

A technology for electronic components and cooling systems, applied in electrical components, semiconductor devices of light-emitting components, cooling/heating devices of lighting devices, etc., can solve the problem of direct cooling without providing heat source, and achieve effective cooling and compact cooling system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

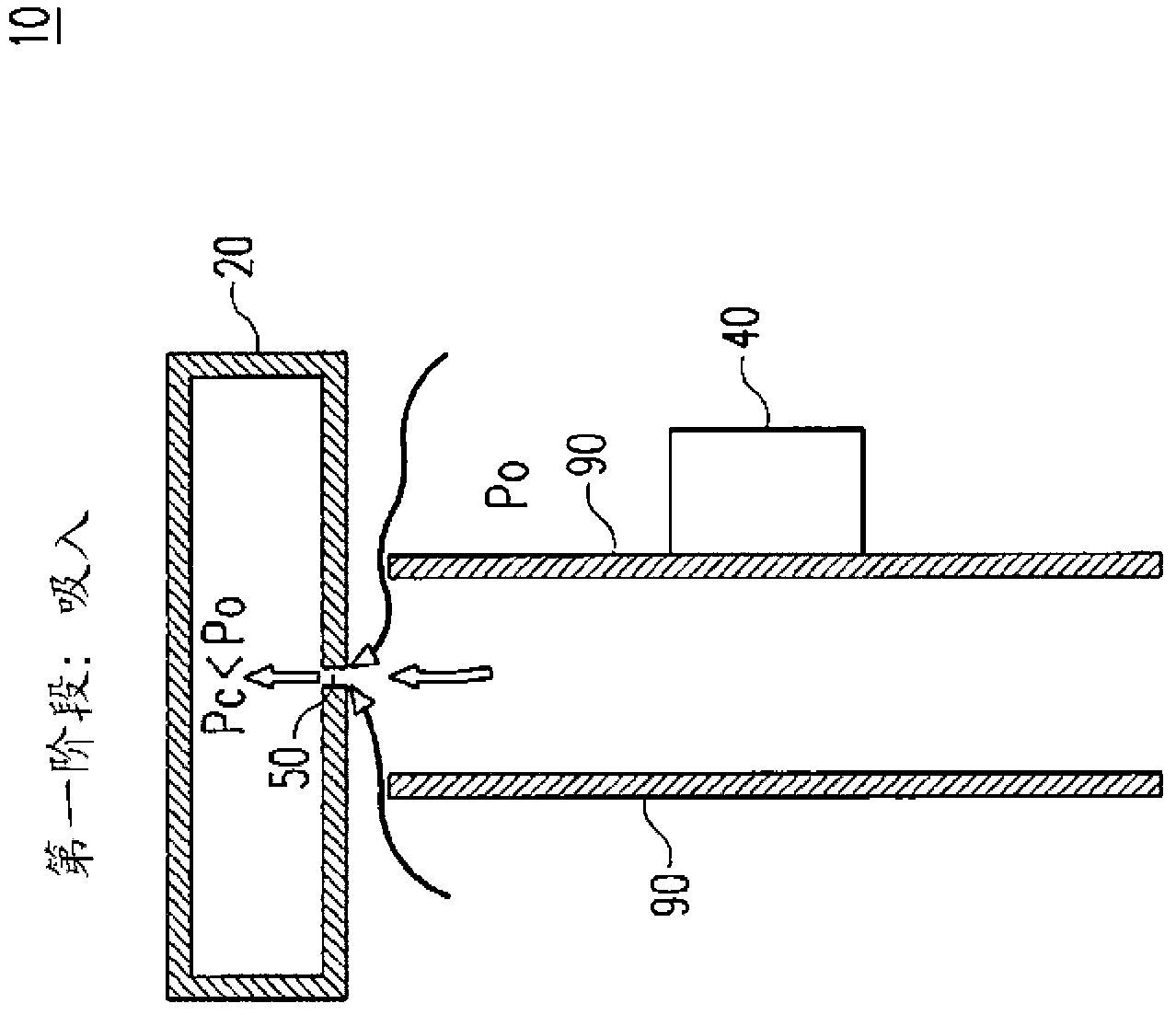

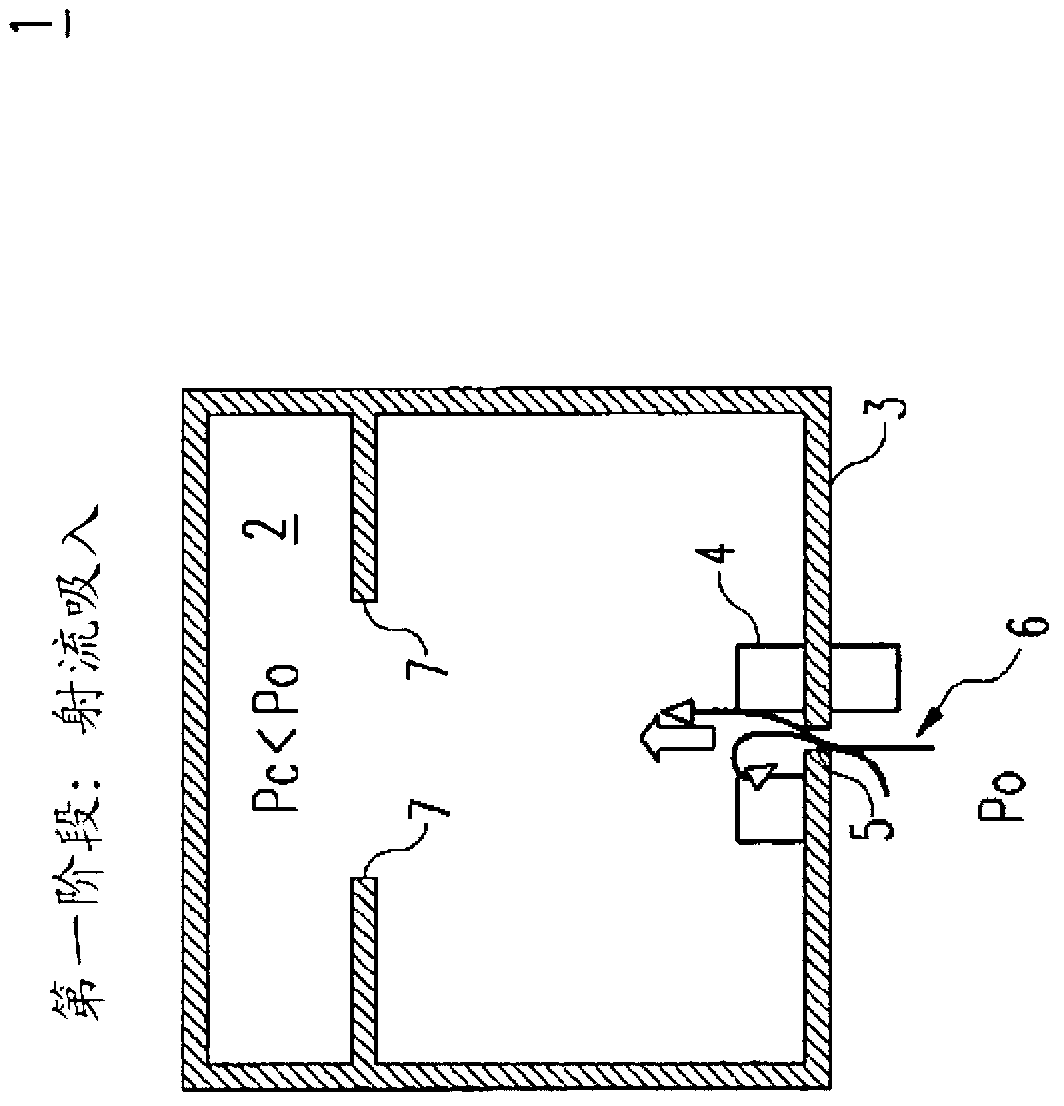

[0032] Figure 2a with 2b A cooling system 1 according to the invention is shown. The cooling system 1 comprises means for generating cyclic air pressure fluctuations, wherein the electronic components 4 are remote from the pressure generating means 7 . The pressure generating device 7 operates in two stages. Figure 2a The first stage, "Jet Inhalation", is shown. Figure 2b The second stage "jet discharge" is shown. In the first stage, the pressure generating device 7 generates a first air pressure, and in the second stage, the pressure generating device 7 generates a second air pressure, and by periodically moving from the first stage to the second stage and back to the first stage, which generates periodically varying pressures. Two-stage operation is the simplest mode of operation. However, the pressure generating device can also operate in more than two stages. The cooling system 1 also comprises means 5 which generate circulating air jets 6 when affected by the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com