An automatic loading and unloading device

An automatic technology of loading and unloading, applied in the direction of mold separation device, unloading device, mold, etc., can solve the problems of not being able to demould multiple bricks as a whole, reducing production efficiency, and being scratched or damaged greatly. Improve labor productivity, reduce defective products, and reduce demolding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

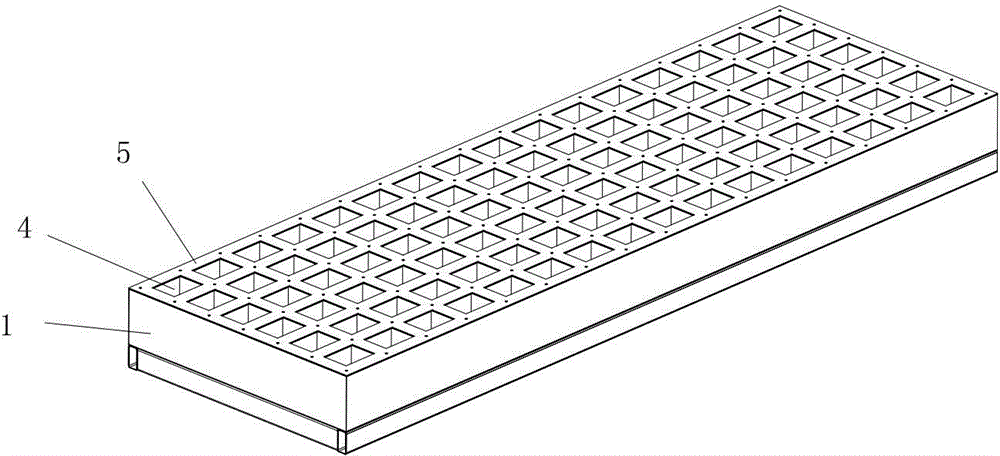

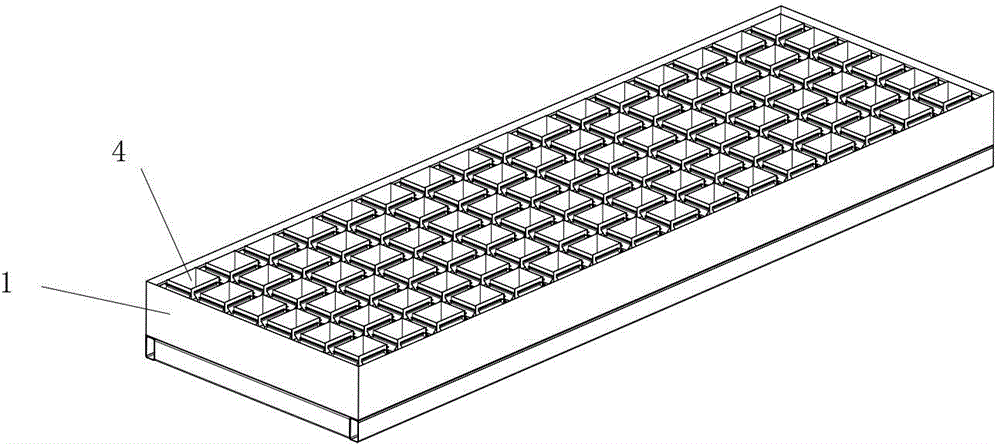

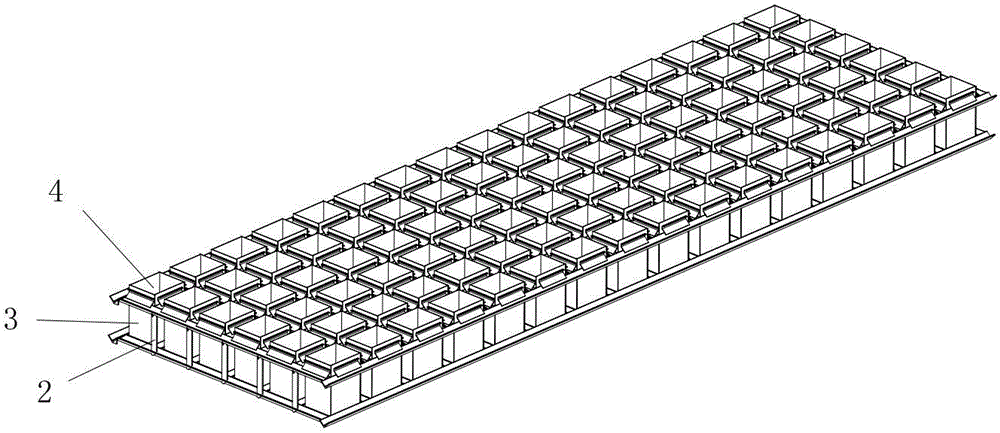

[0022] A kind of automatic loading and unloading device described in this embodiment 1, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, including a frame 1, a formed keel frame 2 is provided in the frame, a rectangular mold cavity 4 assembled from four movable templates 3 is arranged in the keel frame, and a pressing block 5 and an elastic frame are arranged on the top of the keel frame. Pad 6, the keel frame is provided with a positioning inclined guide groove 7 inwardly and upwardly inclined near the upper end, and a bead 8 with a corresponding angle is provided near the bottom of the keel frame; The guide groove cooperates with the sliding limit guide block 9 which forms a corresponding angle with it, and the movable formwork is provided with a positioning pad 10 which cooperates with the bead and forms a corresponding angle with it near the bottom. During production, the entire automatic loading and unloading device is placed on a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com