Scara robot

A technology of robots and servo motors, applied in the field of robots, can solve the problems of insufficient overall structural layout and insufficient rigidity, and achieve the effects of good dynamic response capability, high mechanical efficiency, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further illustrate the technical means and functions adopted by the present invention to achieve the predetermined invention goal, the specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

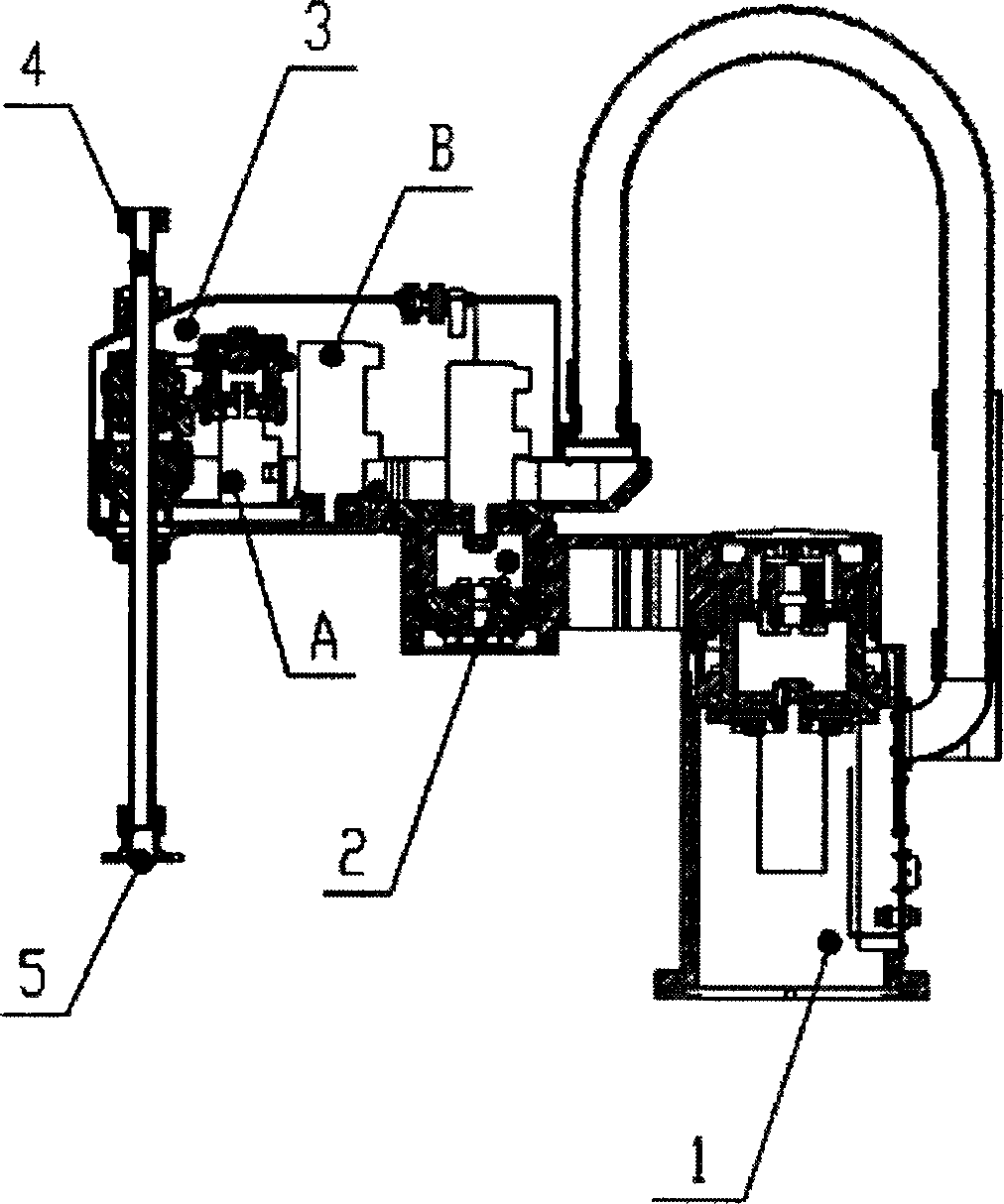

[0026] Such as Figure 1~6 The Scara robot shown is driven by an absolute encoder type full servo, and its main structure includes a first rotary joint 1, a second rotary joint 2, a rotary-moving compound motion joint 3, a spline screw 4, and an end working device.

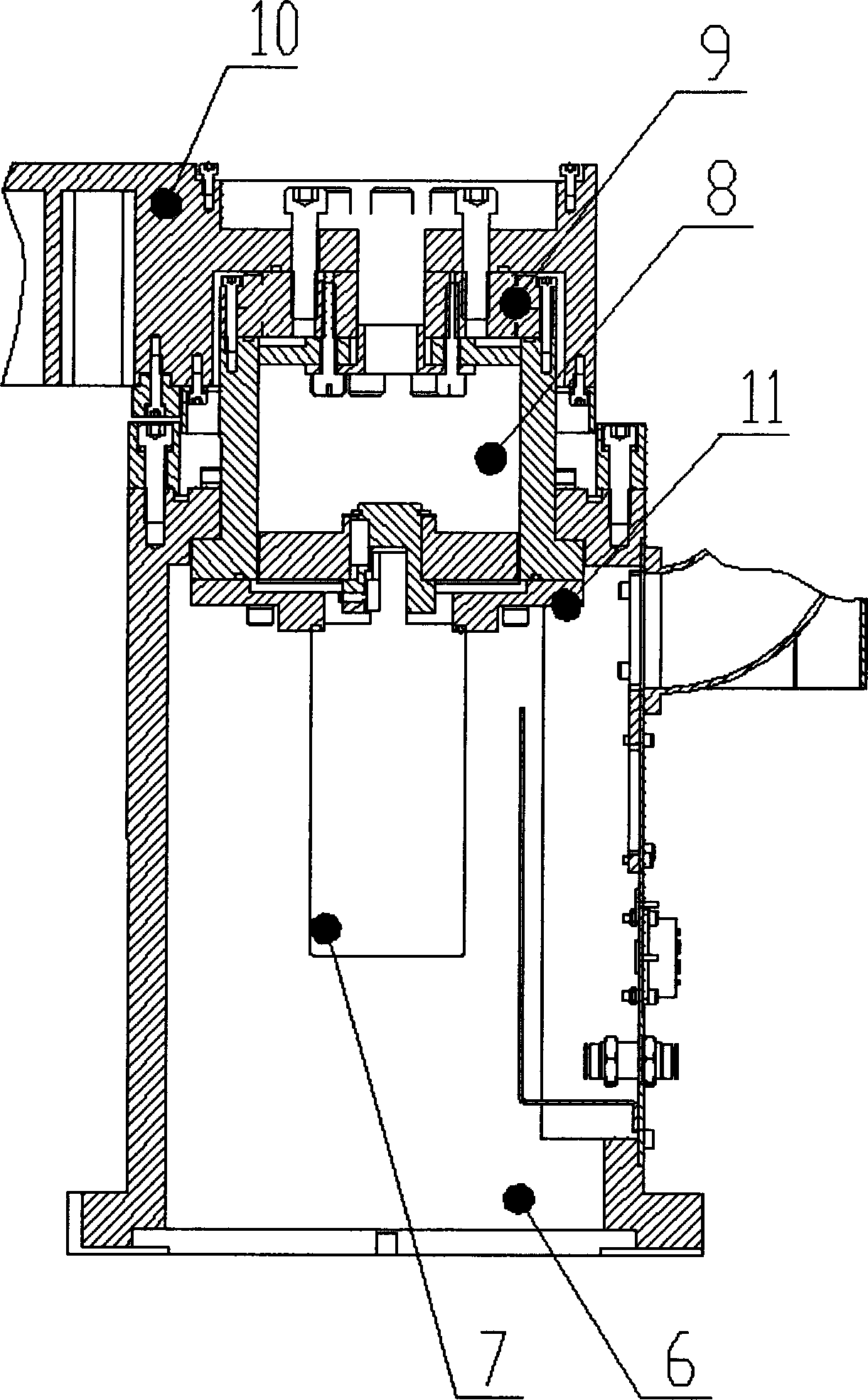

[0027] The first rotary joint 1 is driven by a servo motor 7, and the servo motor 7 is connected to the steel wheel of the first harmonic reducer 8 through the motor connection flange 11, and the steel wheel of the first harmonic reducer 8 is fixed on the first rotary On the base 6 of the joint 1, it is fixed by a steel wheel, and the flexible spline output installation structure, the first harmonic reducer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com