Rotary kiln barrel base plate mounting device

A technology for installing devices and rotary kilns, which is applied in metal processing, metal processing equipment, manufacturing tools, etc. It can solve the problems of restricting the production speed of rotary kilns, high labor intensity of workers, and low installation efficiency, so as to realize the automatic operation of cylinder installation , Reduce labor intensity and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

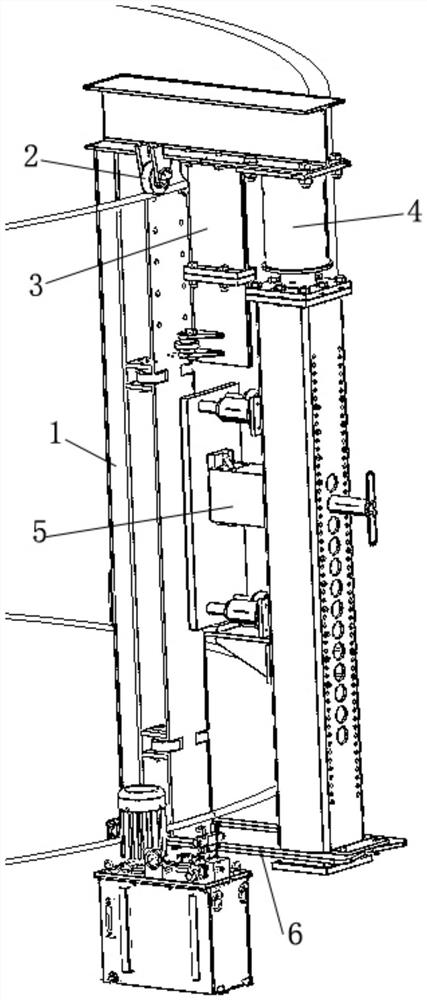

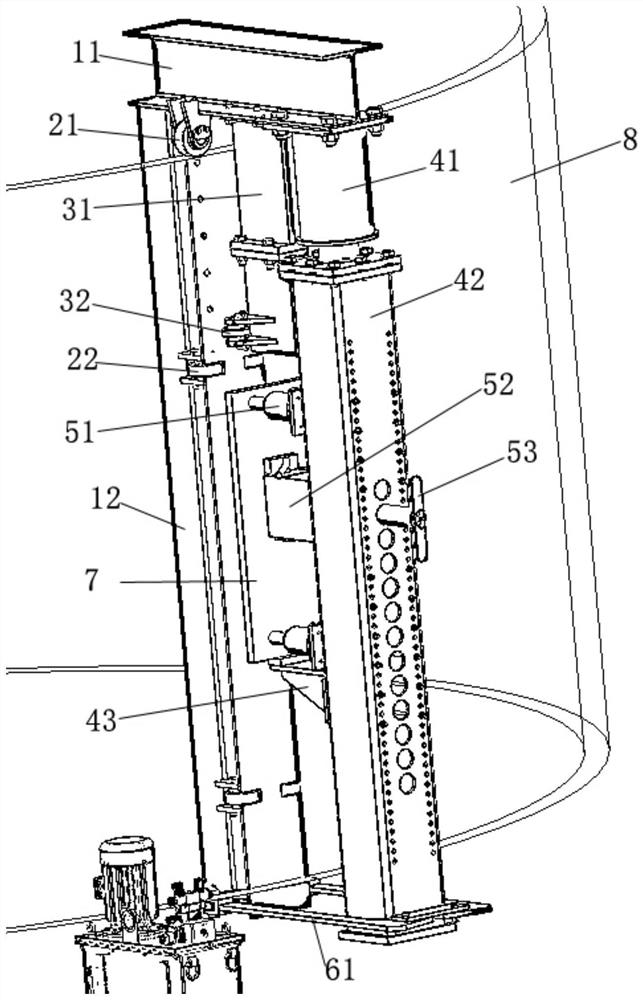

[0023] Such as figure 1 and figure 2 As shown, a rotary kiln shell backing plate installation device provided by the present invention consists of a support frame 1, a traveling wheel mechanism 2, a limit wheel mechanism 3, a rotating mechanism 4, a backing plate holding and pressing mechanism 5, and a locking mechanism 6 And hydraulic station etc. composition.

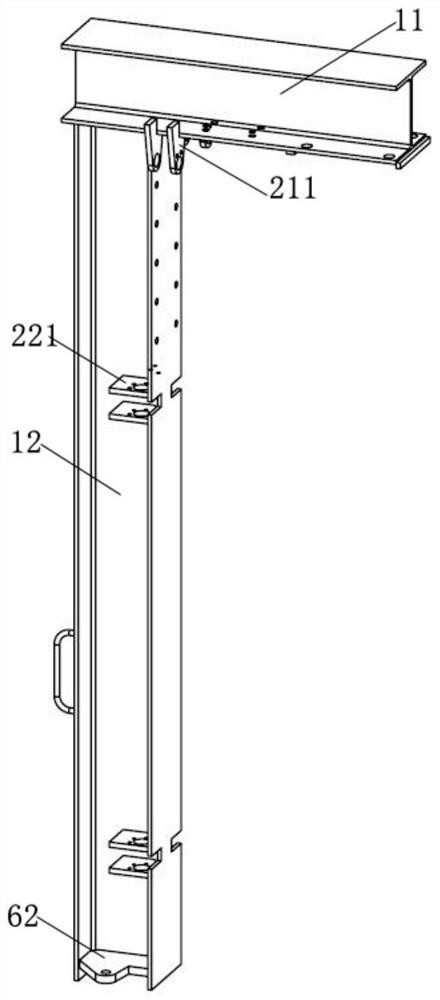

[0024] see image 3 , the support frame 1 is composed of a beam 11 and a support column 12, the beam 11 and the support column 12 are divided into an I-shaped steel structure, the upper end of the support column 12 is fixedly connected with the lower surface of one end of the beam 11, and the lower surface of the beam 11 on the right side of the support column 12 A plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com