Block-shaped infantile milk powder and preparation method thereof

A milk powder and infant technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of poor forming, preparation defects, and inability to solve the preparation defects of powdered infant formula milk powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

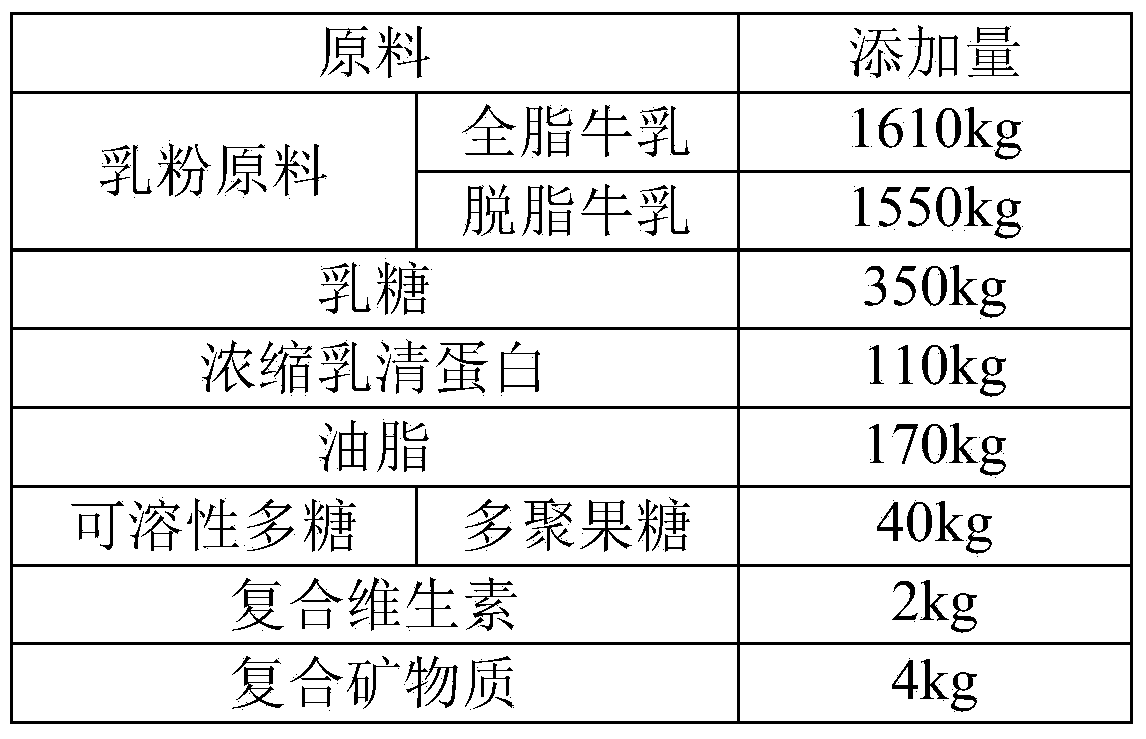

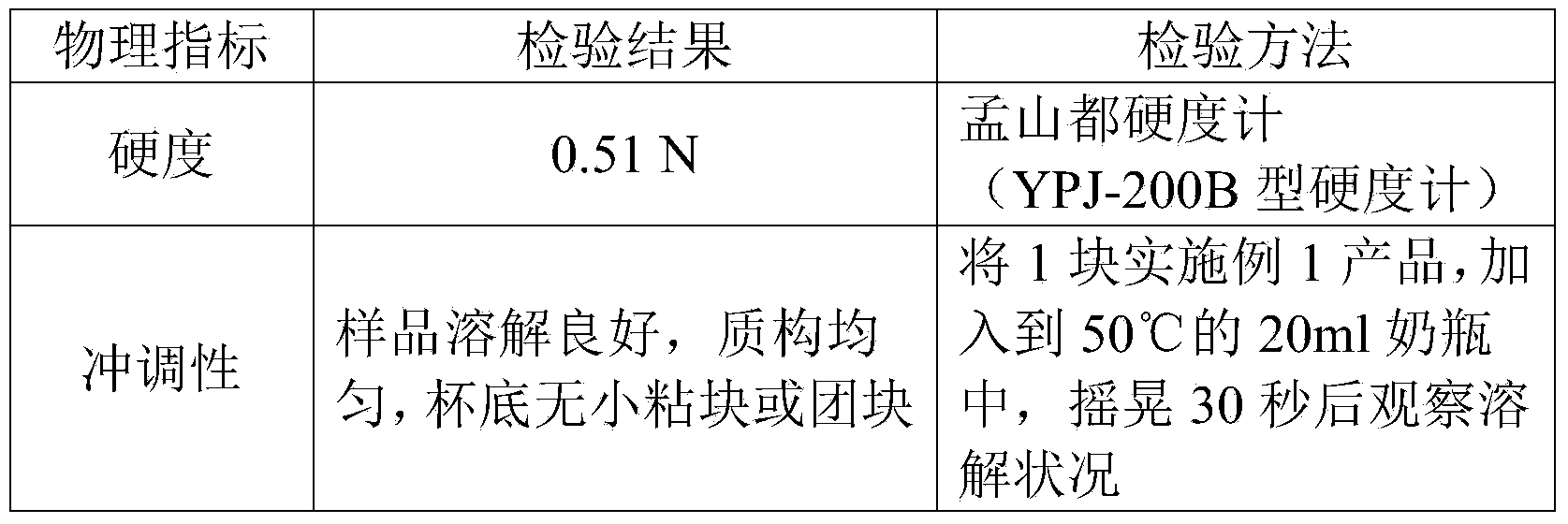

[0078] The raw material formula of table 4 embodiment 1

[0079]

[0080] The preparation process is as follows (taking the production of 1 ton of milk powder as an example):

[0081] (1) Ingredients: Pour 3000kg of demineralized water into the ingredient tank, start the vacuum mixer and stirring pump, heat up to 45°C, then add oil, multivitamins, multiminerals, and concentrated whey protein into the vacuum mixer pink. The grease is preheated to 45°C and mixed evenly before feeding. The compounding method of compound vitamins and compound minerals: the vitamins and minerals are pre-dissolved in 9 times the weight of water at 30°C and then added. After circulating and mixing with a vacuum mixer for 15 minutes, it was mixed with pretreated whole milk and skim milk to obtain feed liquid A with a solids concentration of 14% (wt).

[0082] (2) Flour making: First, carry out two-stage homogenization of the material liquid A, wherein the first-stage homogeneous pressure is 20MP...

Embodiment 2

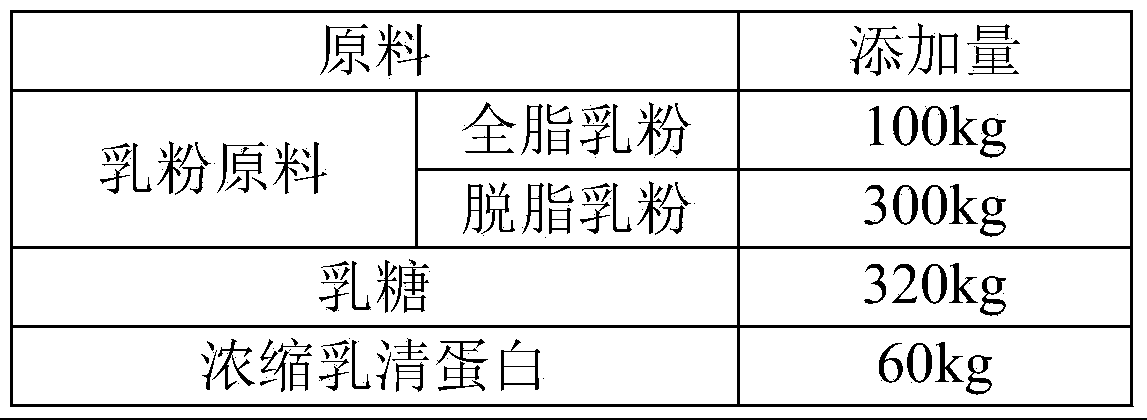

[0093] The raw material formula of table 7 embodiment 2

[0094]

[0095]

[0096] The preparation process is as follows (taking the production of 1 ton of milk powder as an example):

[0097] (1) Ingredients: Pour 4400kg of demineralized water into the ingredients tank, start the vacuum mixer and stirring pump, heat up to 50°C, first add whole milk powder, skimmed milk powder, oil, and multivitamins into the vacuum mixer , Complex Minerals, Concentrated Whey Protein Powder. The grease is preheated to 55°C and mixed evenly before feeding. The compounding method of compound vitamins and compound minerals: the vitamins and minerals are pre-dissolved with 10 times the weight of water at 40°C and then added. After circulating and mixing for 20 minutes with a vacuum mixer, the material liquid A was obtained, and the solids concentration was 18% (wt).

[0098] (2) Flour making: First, carry out two-stage homogenization of the material liquid A, wherein the first-stage homog...

Embodiment 3

[0110] The raw material formula of table 10 embodiment 3

[0111]

[0112] The preparation process is as follows (taking the production of 1 ton of milk powder as an example):

[0113] (1) Ingredients: Pour 5000kg of demineralized water into the ingredients tank, start the vacuum mixer and stirring pump, heat up to 48°C, first add whole milk powder, skimmed milk powder, oil, and multivitamins into the vacuum mixer , Complex Minerals, Concentrated Whey Protein Powder. The fat is preheated to 50°C before feeding and mixed evenly. The compounding method of compound vitamins and compound minerals: the vitamins and minerals are pre-dissolved with 11 times the weight of water at 35°C and then added. After circulating and mixing for 17 minutes with a vacuum mixer, the material liquid A was obtained, and the solids concentration was 16% (wt).

[0114] (2) Flour making: First, carry out two-stage homogenization of material liquid A, wherein the first-stage homogeneous pressure is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water content | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com