Conveyor belt system and conveyor belt

A technology for conveyor belts and belt sections, applied in the direction of conveyors, transportation and packaging, etc., which can solve problems such as increased friction, and achieve the effects of improved elongation characteristics, small shape changes, and easy shape changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

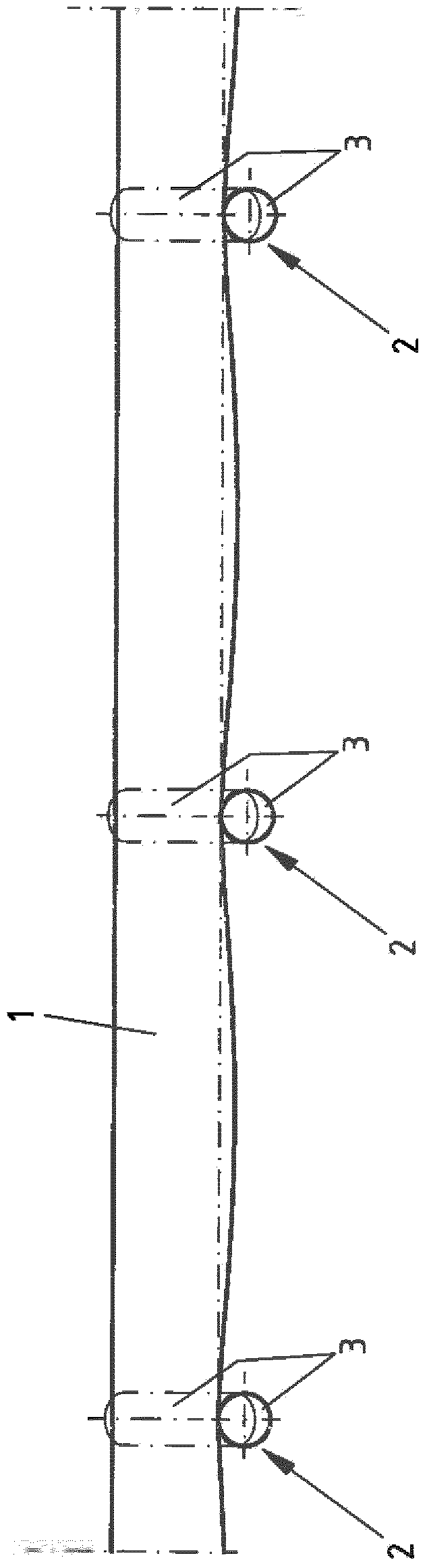

[0034] figure 1 A side view is provided depicting a trough section of a conveyor belt system wherein a conveyor belt 1 extends in the longitudinal direction and a plurality of support roller brackets 2 are spaced apart in the longitudinal direction against which the conveyor belt 1 is supported on support rollers 3. As shown here, the lower edge of the conveyor belt 1 hangs down between the support roller brackets 2 with respect to the horizontal position. The conveyor belt 1 can be designed as a continuous rotating belt, in which the conveyor belt 1 moving back and forth is guided in opposite directions in two planes, one of which lies above the other. However, for reasons of clarity, only the upper part running with the corresponding support rollers 3 is shown.

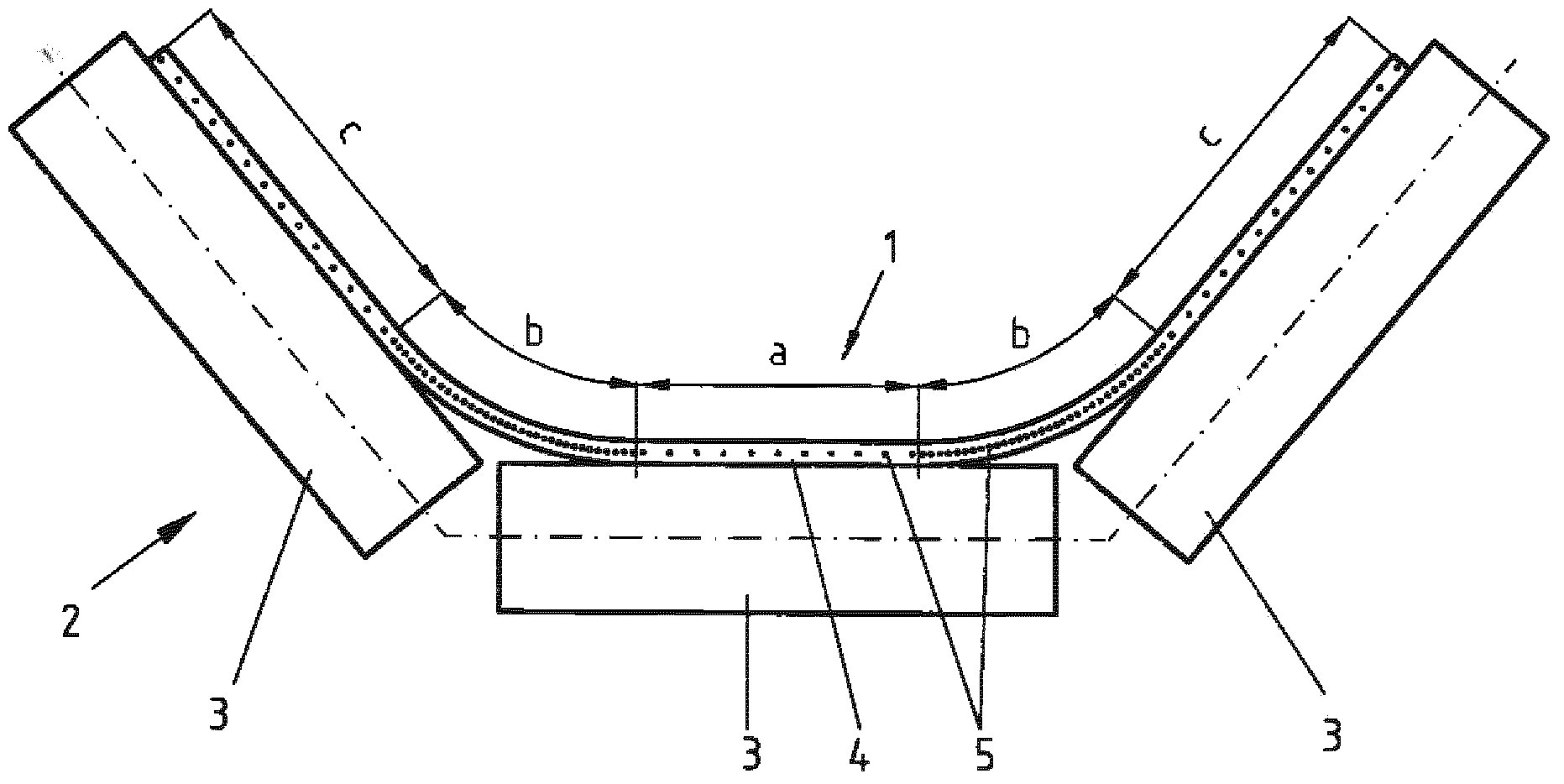

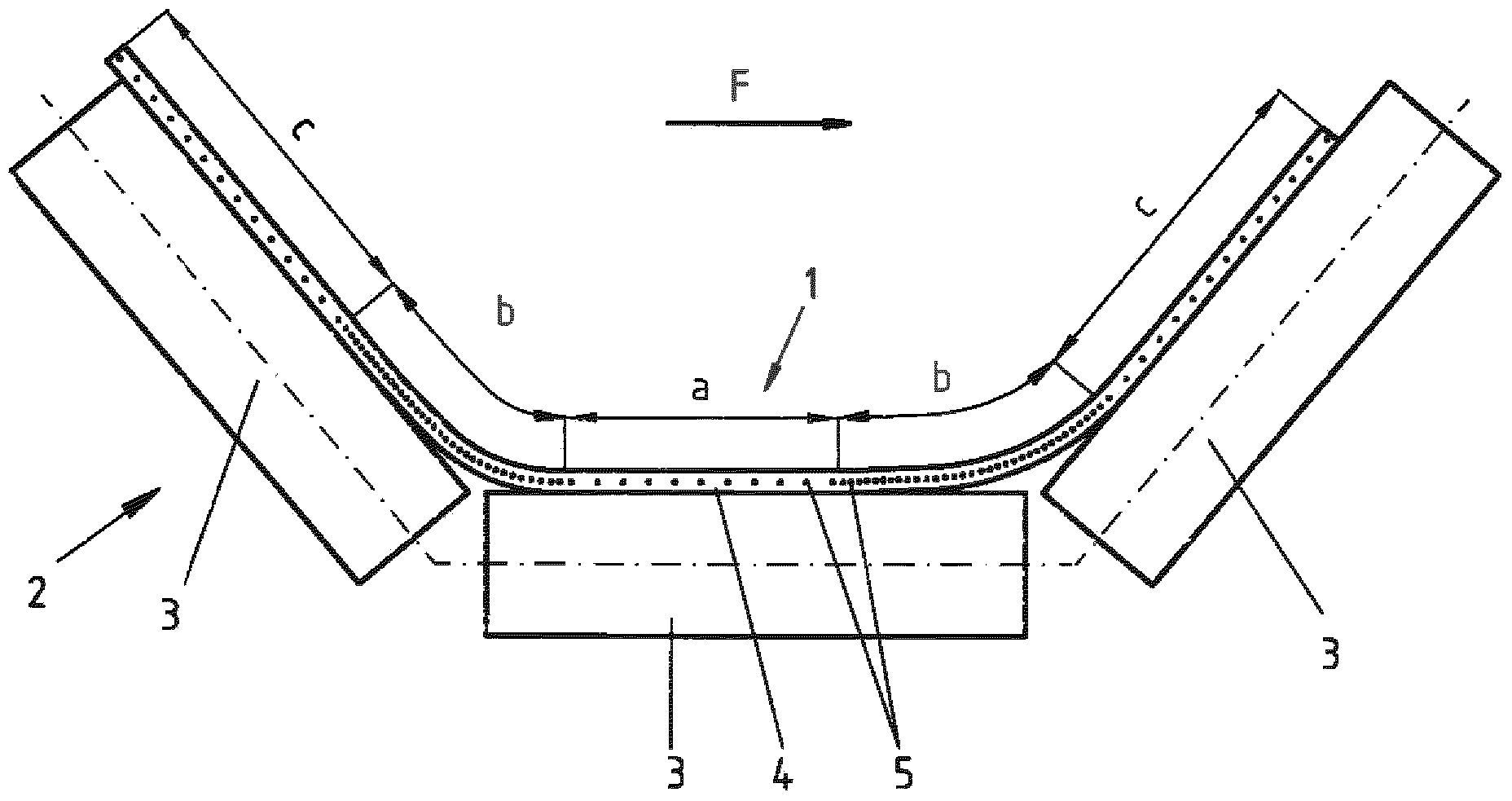

[0035] FIG. 2 a shows a cross section through the conveyor belt 1 in the region of a support roller bracket 2 for the conveyor belt system according to the invention. As shown, the exemplary embodiment shows that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com