Wind-resistant box-type substation and construction method thereof

A box-type substation, pre-installed technology, applied in the field of substations, to achieve the effect of easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

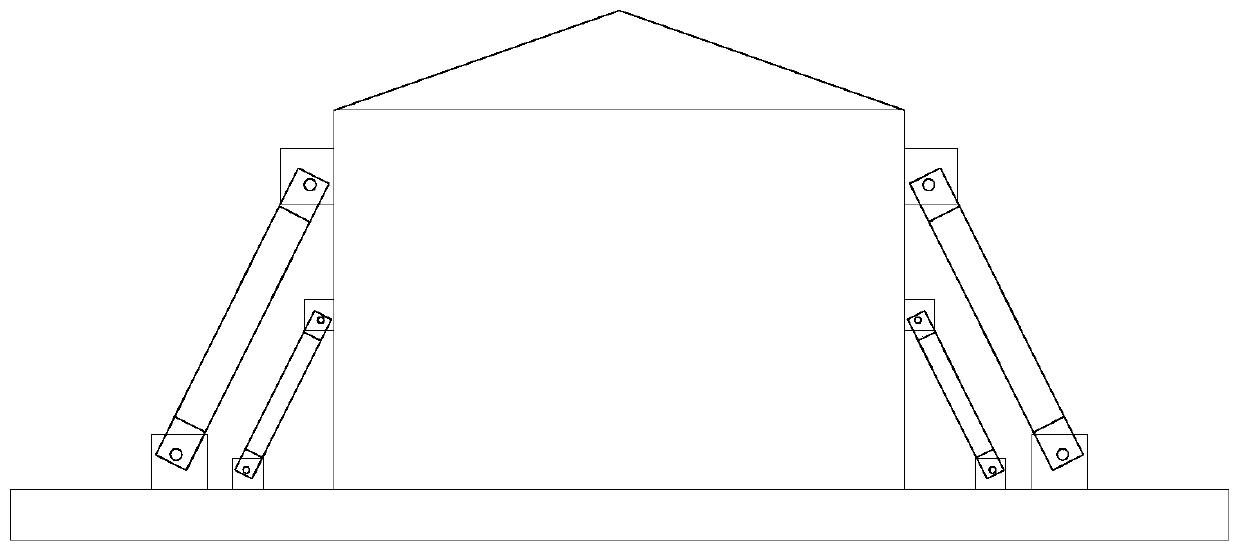

[0037] Embodiment 1: A wind-resistant prefabricated box-type substation, with an oblique energy dissipation support 1 installed between the wall board and the bottom board;

[0038] The oblique energy dissipation support 1 is assembled from a plurality of oblique energy dissipation support unit bodies 2;

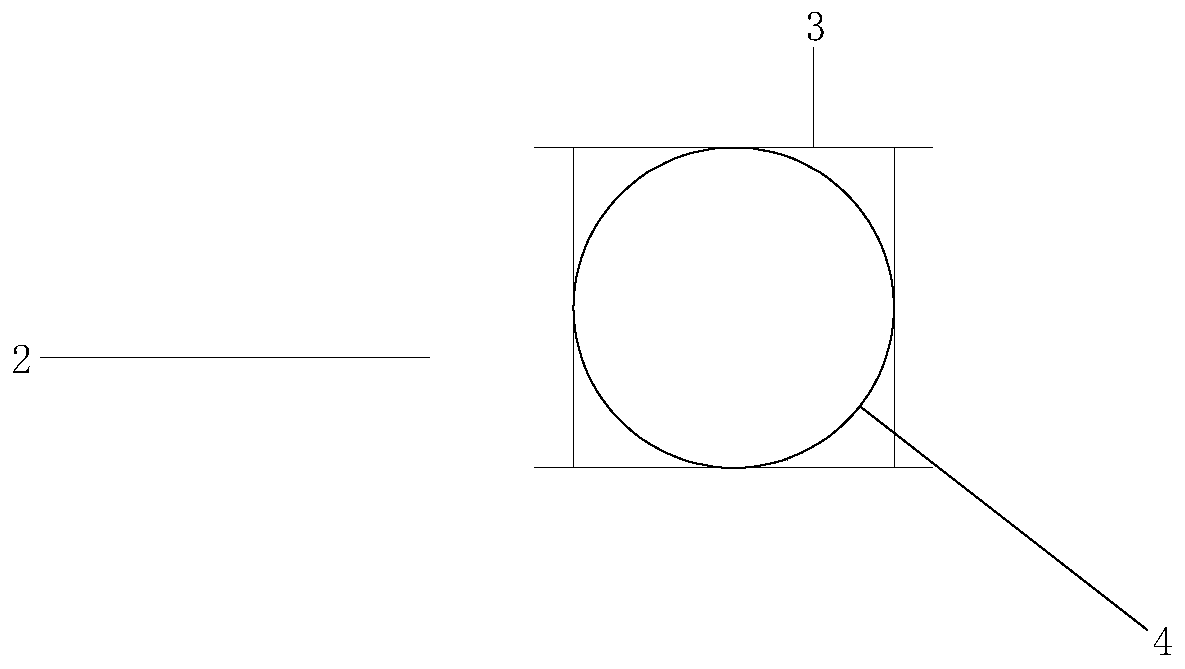

[0039] The oblique energy dissipation support unit body 2 includes: an external frame 3 and an internal cylindrical structure 4; the cross section of the external frame 3 maintains a circumscribed relationship with the circular cross section of the cylindrical structure, wherein the cylindrical structure 4 Using mild steel;

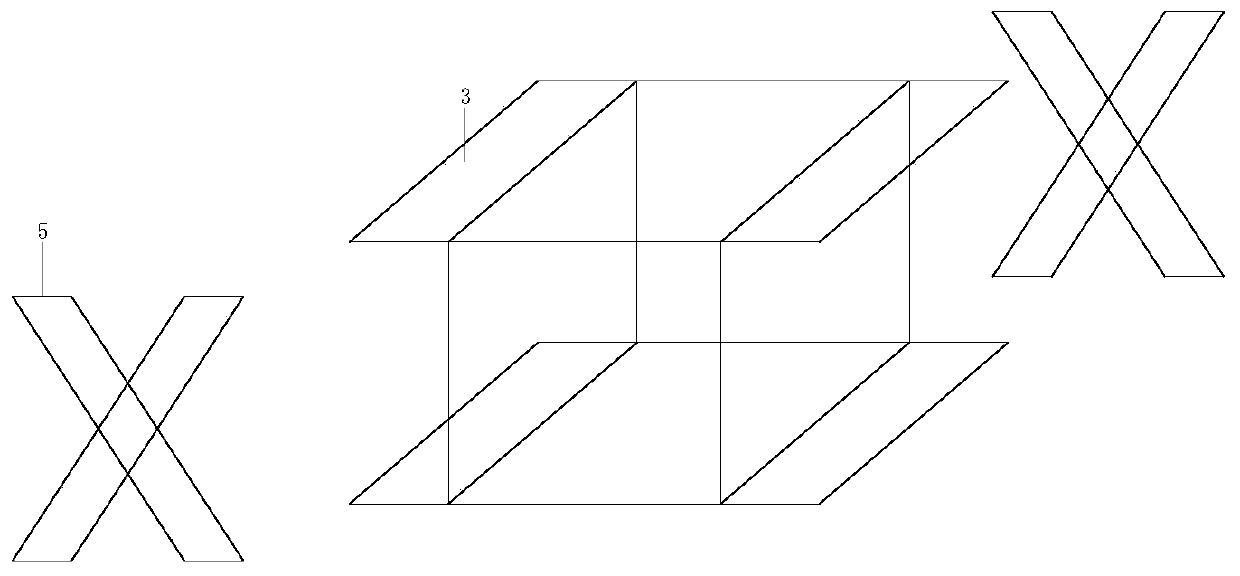

[0040] The frame 3 includes: a top plate, a bottom plate, two vertical side plates, and two X-shaped connecting plates 5;

[0041] The two corresponding surfaces of the frame 3, that is, the surfaces corresponding to the two end surfaces of the cylindrical structure 4, are provided with an X-shaped connecting plate 5;

[0042] The top plate, bottom pl...

Embodiment 2

[0053] Embodiment 2: Although the design of the slanted plate in Comparative Example 1 increases the contact surface between the frame 3 and the cylindrical structure 4, it can exert the energy dissipation capacity of mild steel; however, after adding the slanted plate, the rigidity of the frame 3 is too high. Large, the deformation between the vertical side plate and the top and bottom plates is not easy to occur (soft steel can only play the role of energy consumption after the vertical side plate is tilted), so the connection between the vertical side plate and the top and bottom plates should be reduced strength.

[0054] Such as Figure 7 As shown, it is the design structure of the oblique energy-dissipating support unit body 2 of the second embodiment, the vertical side plate is connected with the top plate and the bottom plate through the oblique plate, and the vertical side plate is no longer extended to the top plate and the bottom plate;

[0055] Such as Figure 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com