General fault detecting and maintenance method for equipment

A technology of fault detection and general equipment, applied in the direction of error detection/correction, special data processing applications, instruments, etc., can solve problems such as difficulty in standardizing and unifying the maintenance process, difficulty in effectively disseminating maintenance knowledge and experience, waste of resources, etc. Achieve the effect of improving maintenance quality, realizing automatic diagnosis and improving maintenance level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be further described below in conjunction with the accompanying drawings.

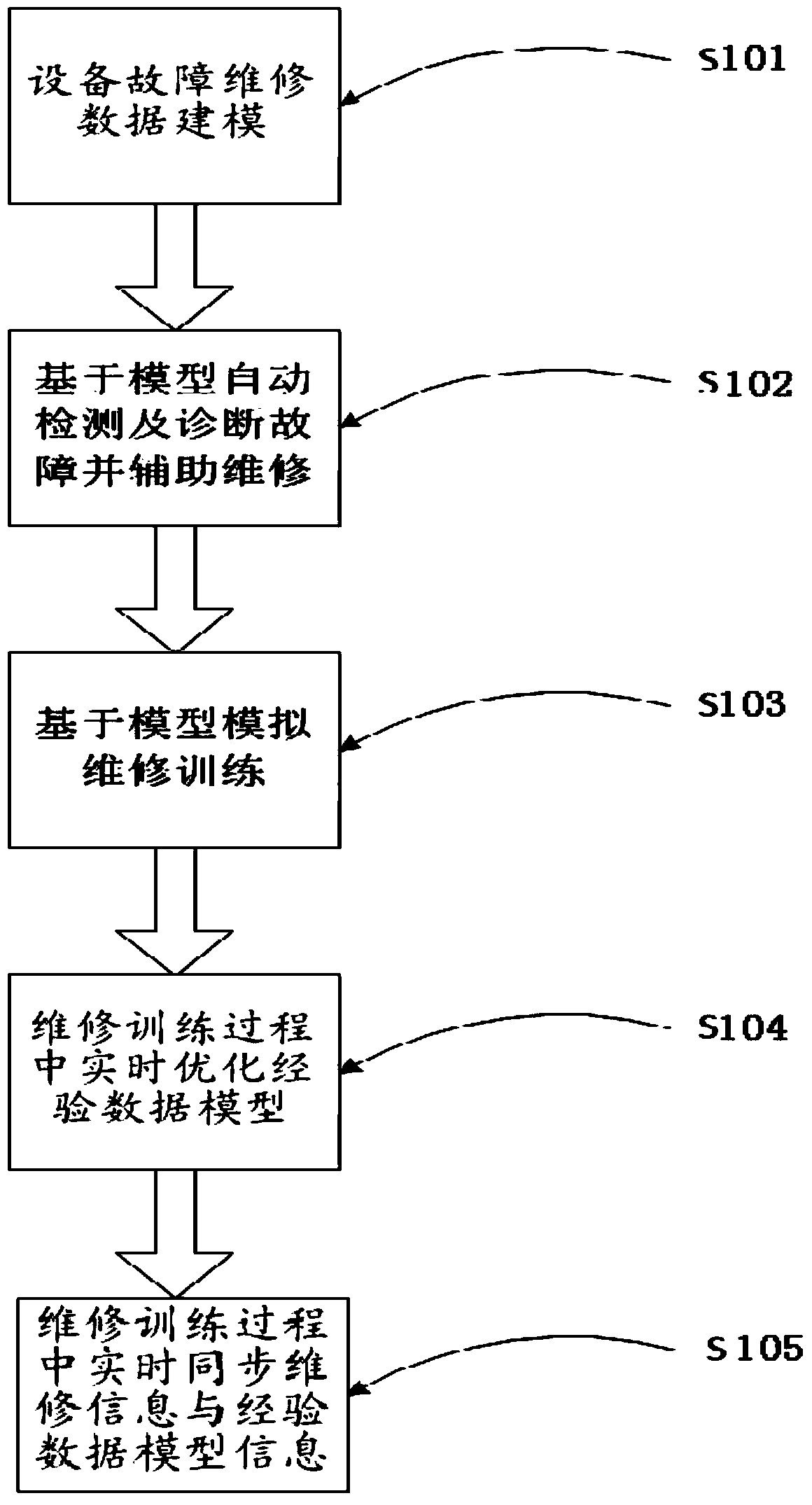

[0074] Such as figure 1 As shown, a kind of general equipment failure detection maintenance method provided by the present invention comprises the following steps:

[0075] S101 Data modeling of equipment failure maintenance

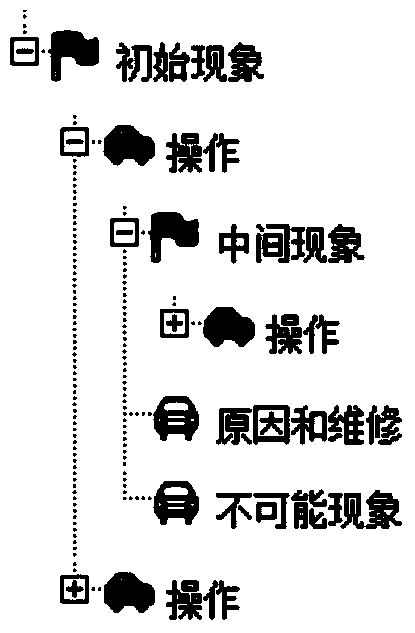

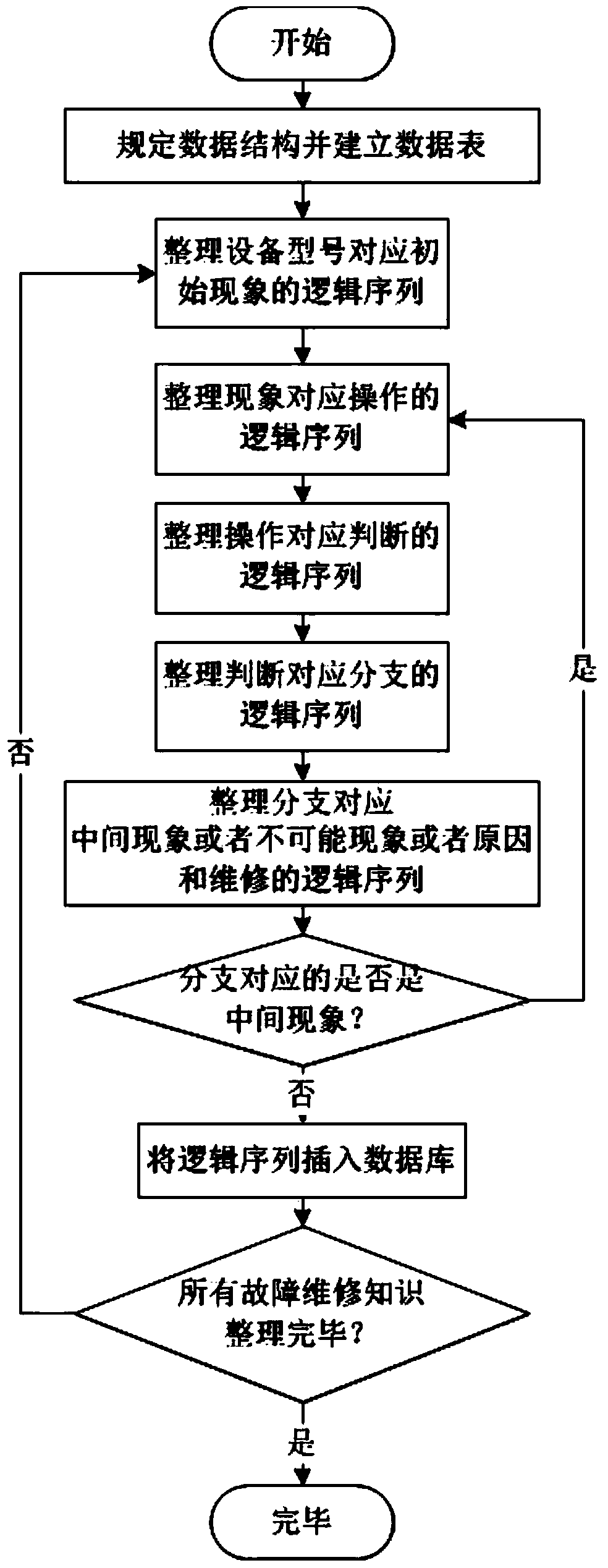

[0076] The fault maintenance data of various equipment is abstracted into a "fault-repair tree" model, and the model is transformed into a database for storage. The model conforms to the basic definition of a tree (data structure), and consists of four types of nodes: "phenomenon" nodes, "operation" nodes, "cause and repair" nodes, and "theoretically impossible" nodes.

[0077] A tree (data structure) is defined as follows:

[0078] a. Each node has zero or more child nodes;

[0079] b. A node without a predecessor is called a root node;

[0080] c. Each non-root node has one and only one parent node;

[0081] d. The remaining data elements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com