Method for measuring content of elements in coal ash

A technology of element content and coal ash, which is applied in the field of analysis and testing to achieve good measurement results and accurate and reliable element content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

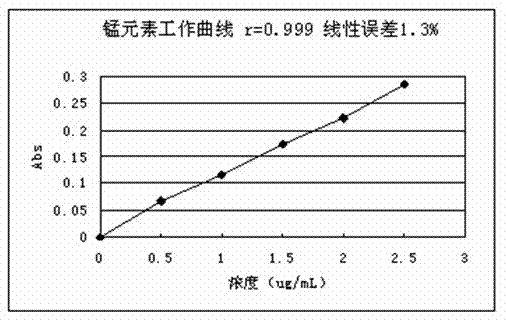

Image

Examples

Embodiment

[0029] A method that can accurately measure the content of potassium, sodium, iron, calcium, magnesium and manganese in coal ash, goes through the following steps:

[0030] 1. Preparation of mixed standard working solutions

[0031] 1.1. Preparation of iron, calcium and magnesium standard solutions: draw 10 mL of iron standard stock solution with a concentration of 1000 μg / mL, calcium standard stock solution with a concentration of 1000 μg / mL, and magnesium standard stock solution with a concentration of 1000 μg / mL, respectively, and divide them into 10 mL. Put it in a 100mL volumetric flask, add water to dilute to the mark, shake well, and obtain standard solutions of iron, calcium and magnesium with a concentration of 100μg / mL;

[0032] 1.2. Preparation of potassium, sodium and manganese standard solutions: draw 1 mL of potassium standard stock solution with a concentration of 100 μg / mL, 1 mL of sodium standard stock solution with a concentration of 100 μg / mL, and 1000 μg / mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com