Reflectivity and transmittance comprehensive measurement method based on pulse laser light source

A pulsed laser, comprehensive measurement technology, applied in the direction of testing optical performance, etc., can solve the problems of inability to accurately measure reflectivity, spectrophotometric devices cannot be accurately measured, etc., to achieve the effect of simple and convenient switching and simplifying the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

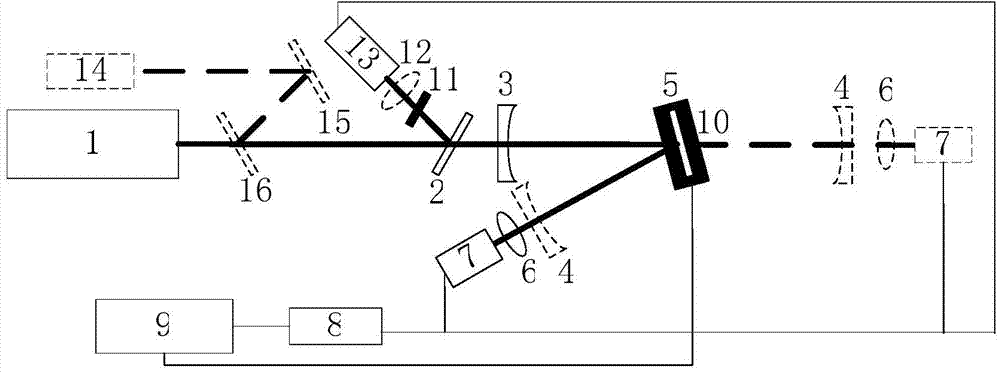

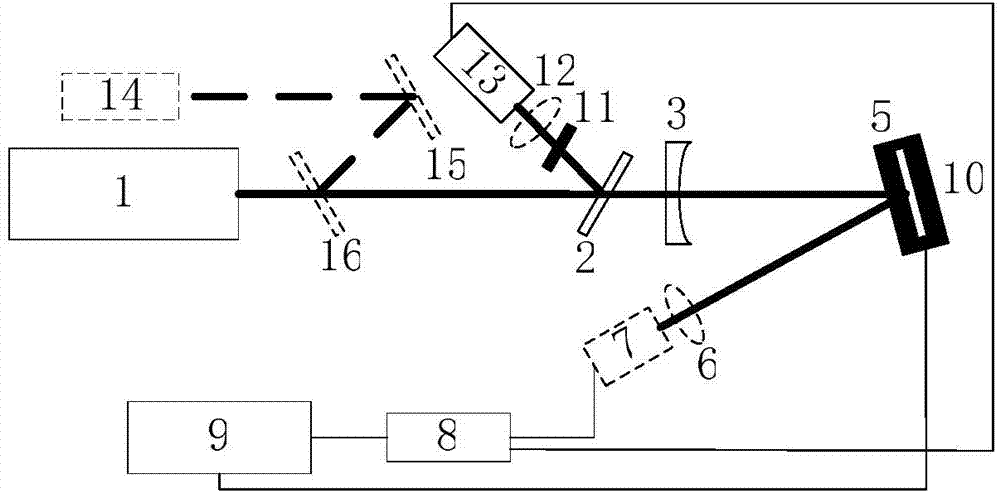

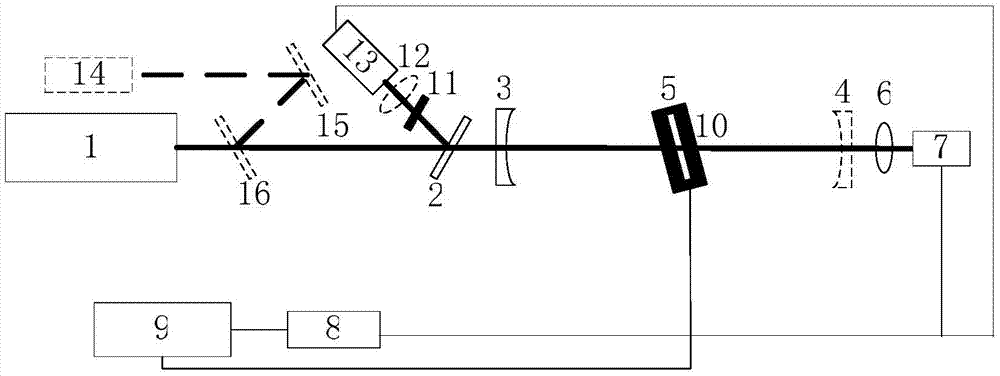

[0025] Combine below Figure 1 to Figure 3 The measurement system describes a comprehensive measurement method of reflectivity based on a pulsed laser light source of the present invention.

[0026] The light source 1 is a pulsed laser, the laser output pulse line width is greater than the free spectral range of the resonator; the pulsed laser beam is split into a reference beam and a detection beam by the plane high reflector 2, and the reference beam is attenuated by the variable attenuator 11 and then passed by the focusing lens 12 Focus on the photodetector 13, adjust the variable attenuator 11 to make the light intensity of the reference beam equal to the light intensity of the detection beam; the output signals of the photodetectors 7 and 13 are collected by the data acquisition card 8 and input to the computer 9 for storage and processing; visible auxiliary The light source 14, reflector 15 and beam splitter 16 are used to assist in adjusting the optical path. If the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com