Diesel injector capable of successively injecting oil

A diesel engine and fuel injector technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems that the installation position of the fuel injector cannot be guaranteed, high cost, and the strength of the cylinder head is reduced, so as to improve fuel atomization Performance, efficiency improvement, effect of reducing soot and HC emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

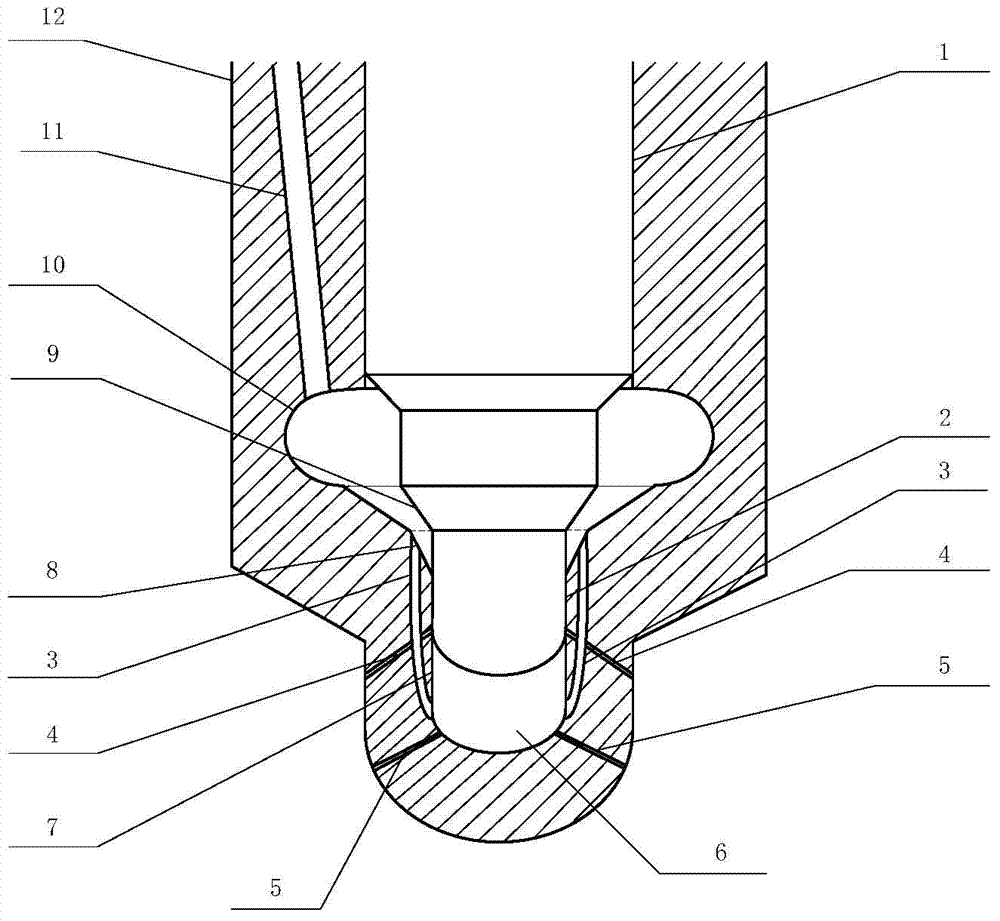

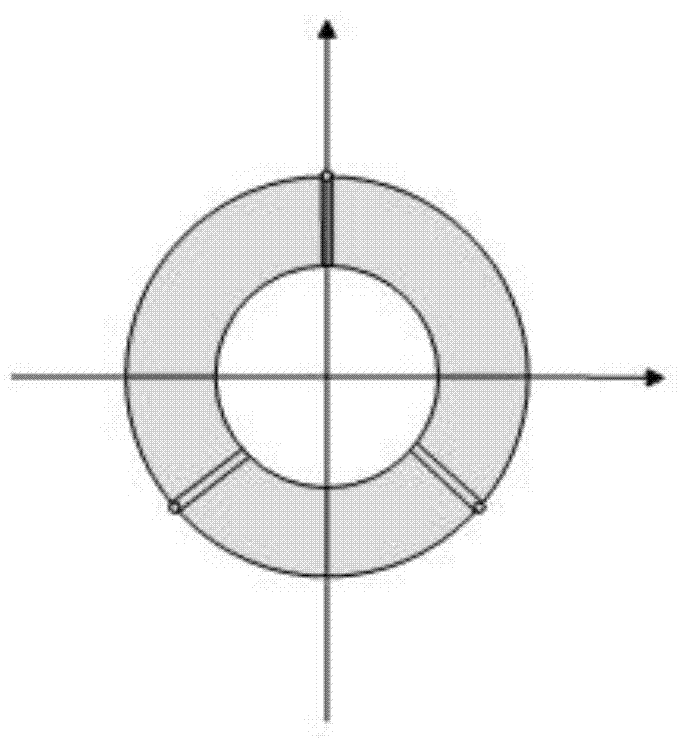

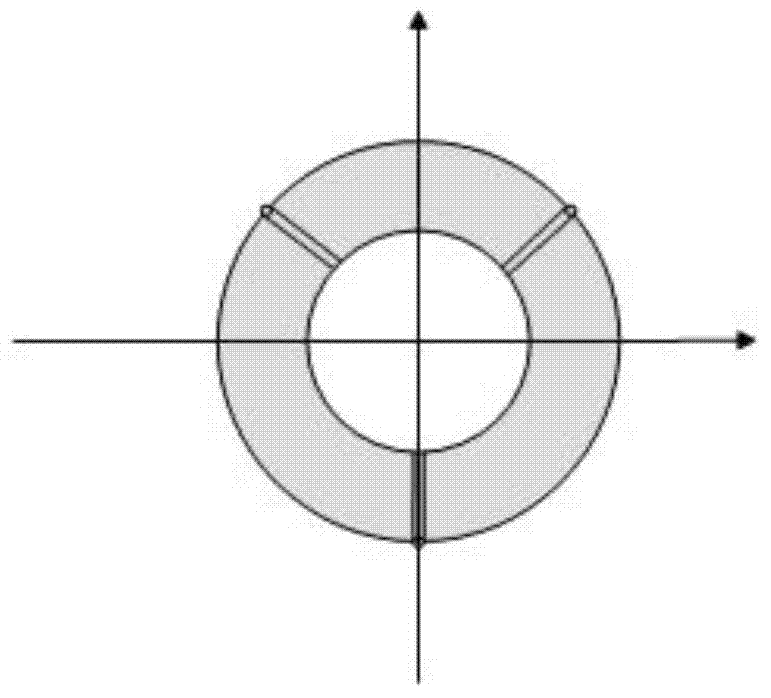

[0012] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0013] combine Figure 1~3 , the needle valve body 1 of the present invention follows the form of the traditional fuel injector, and the main innovations are the improvement of the bottom of the needle valve, the design of the fuel injection hole, and the design of the channel 3 to realize the change of the input fuel injection according to the fuel injection volume. A function of the number of orifices. by figure 1 Shown to illustrate the positional relationship of the main components of the present invention:

[0014] The needle valve cone surface 9 is in the shape of a conical surface at the bottom of the needle valve body 1, and when the needle valve body 1 is seated, it is precisely matched with the needle valve sealing surface 8 below; The upper and lower ends of the sealing surface 8 are opened at the bottom of the injection chamber 6; the sealing piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com